Household bean curd mask mud manufacturing device based on space moving shear stress

A technology for space movement and manufacturing devices, which is applied in the direction of medical preparations containing active ingredients, dressing preparations, skin care preparations, etc. It can solve problems such as crushing and lack of suitable tofu, and achieve rapid lifting of connecting columns, rotation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

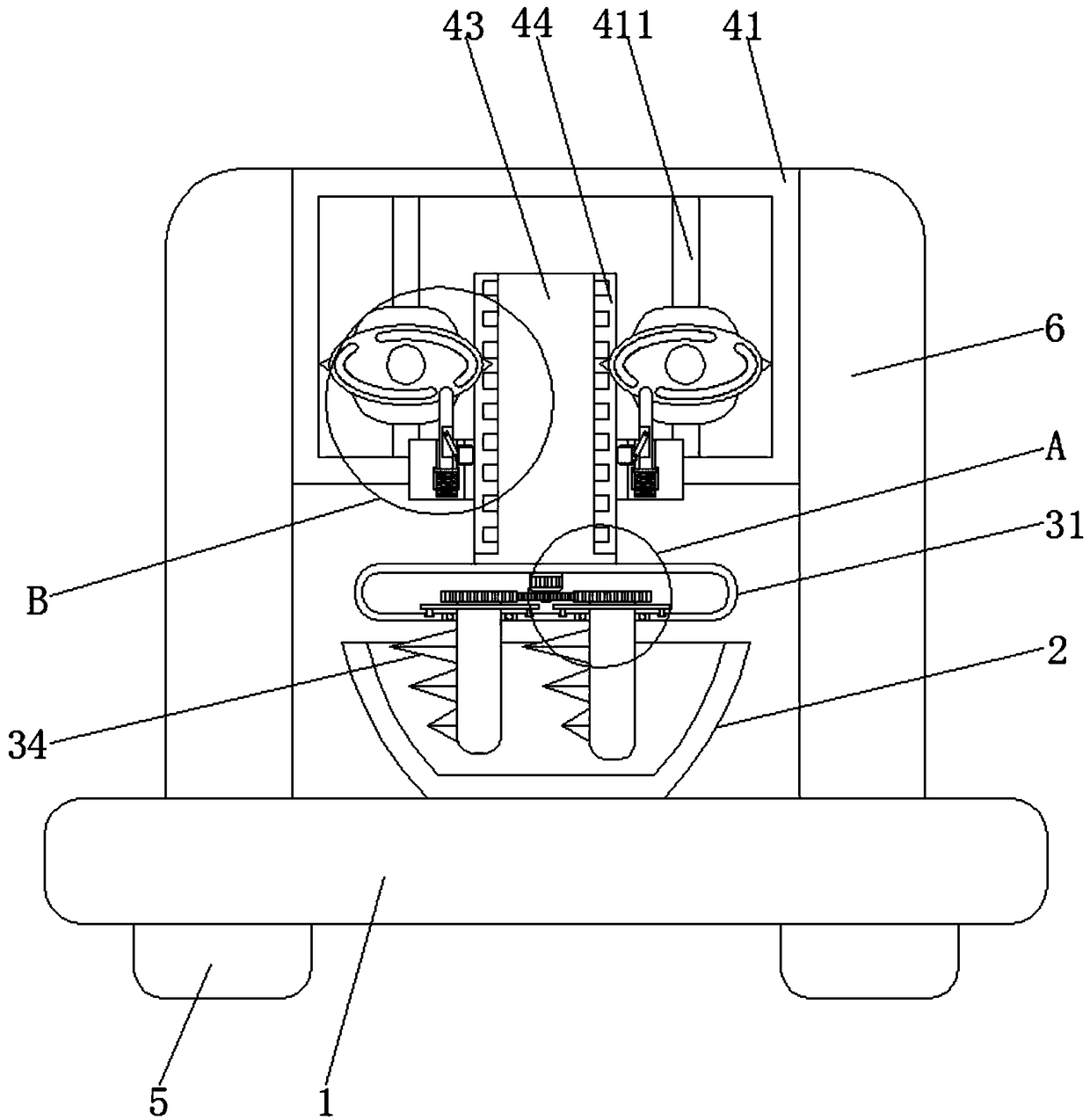

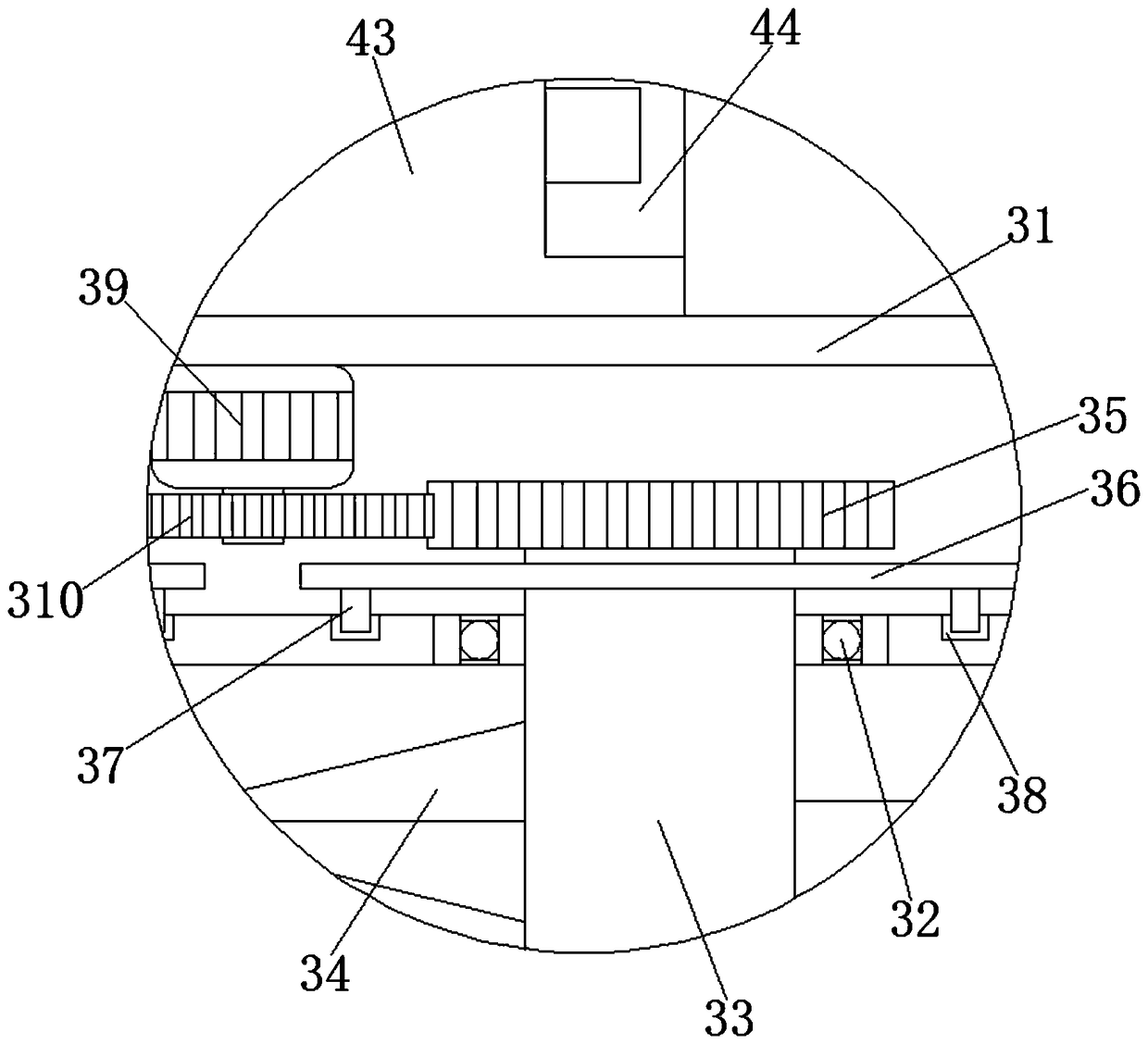

[0031] Such as Figure 1-5 As shown, a household bean curd facial mask mud manufacturing device based on spatial movement shear stress includes a bearing platform 1, the two sides of the bottom of the bearing platform 1 are symmetrically fixedly connected with support legs 5, and the two sides of the top of the bearing platform 1 are symmetrically fixedly connected with supports The column 6 is fixedly connected with the holding bowl 2 in the middle of the top of the bearing platform 1, the driving mechanism 3 is arranged in the middle of the top of the bearing platform 1, and the lifting mechanism 4 is arranged between the tops of the supporting columns 6 on both sides, and the driving mechanism 3 includes a pressure bearing plate 31, the two sides of the bottom of the pressure bearing plate 31 are symmetrically provided with a first opening, the first opening is fixedly connected with a bearing 32, the two sides of the bottom of the pressure bearing plate 31 are symmetrically...

Embodiment 2

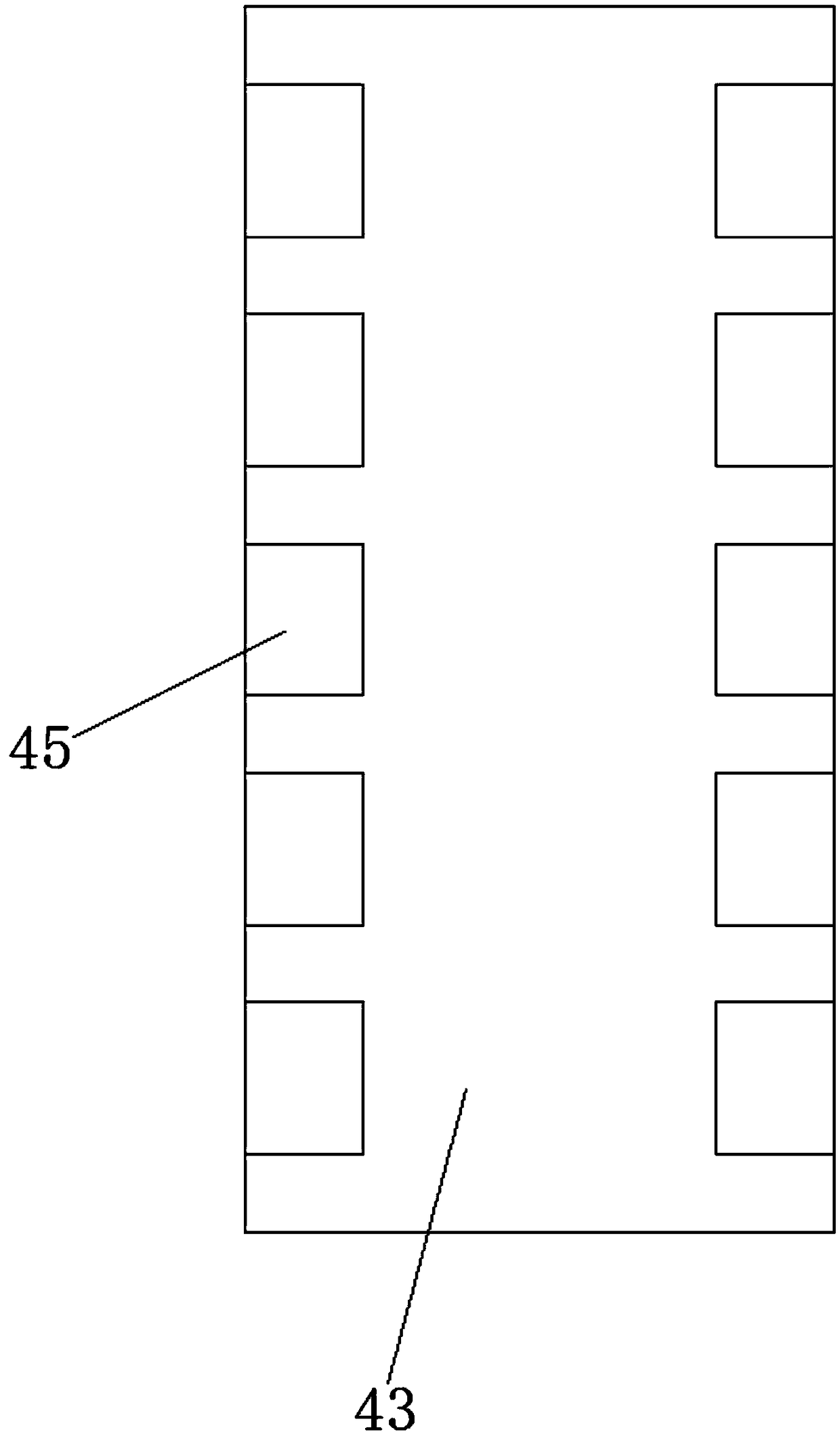

[0033] On the basis of Embodiment 1, the lifting mechanism 4 includes a load-bearing beam column 41, a second opening is provided in the middle of the bottom of the load-bearing beam column 41, a fixing device 42 is provided at the second opening, and a connection is provided in the middle of the bottom of the load-bearing beam column 41. The column 43 is symmetrically provided with tooth grooves 44 in the middle of both sides of the connecting column 43 , and the front of both sides of the connecting column 43 is symmetrically provided with fixing grooves 45 .

Embodiment 3

[0035]On the basis of Embodiments 1 and 2, a second motor 46 is symmetrically fixedly connected to both sides of the bottom of the inner wall of the load-bearing beam column 41, and an output shaft extends from the front of the second motor 46, and the end of the output shaft of the second motor 46 is fixedly connected. There is a rotating shaft 47, the middle part of the rotating shaft 47 is fixedly connected with a runner 48, the two ends of the runner 48 are symmetrically fixedly connected with gear teeth 49, the top and bottom of the runner 48 front are symmetrically fixedly connected with a bead 410, and the second motor 46 A first support rod 411 is fixedly connected to the center of the top, and a second support rod 412 is fixedly connected to the center of the bottom of the second motor 46 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com