Hundred-level gas cleaning type detoxifying cabinet

A detoxification cabinet, 100-level technology, applied in the field of laboratory equipment, can solve the problems of many dead corners and blind areas in detoxification, high energy consumption of detoxification cabinets, waste of laboratory operating costs, etc., to avoid erosion and serious threats, and meet air cleanliness Requirements, reduce the effect of detoxification dead corner blind area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

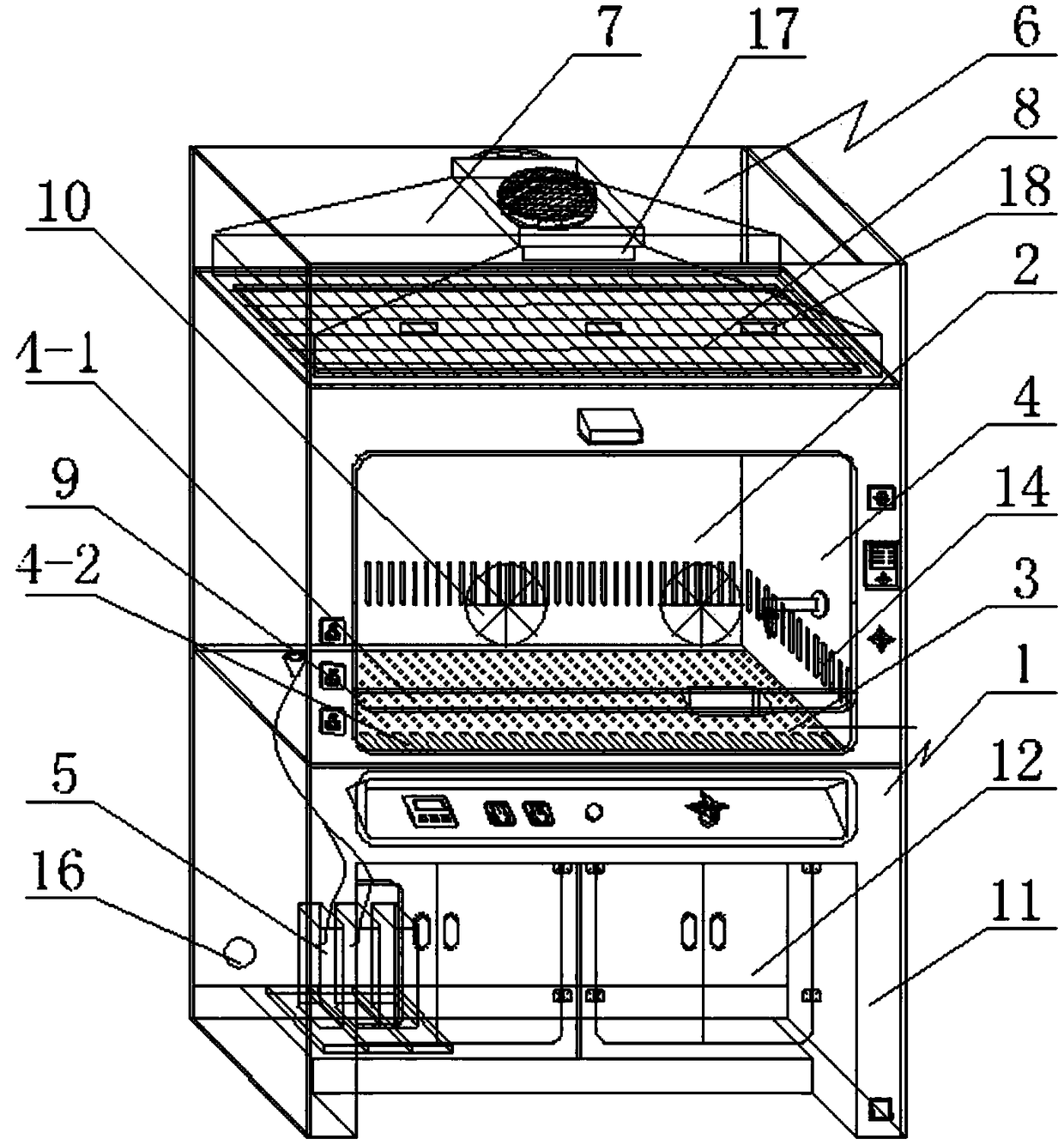

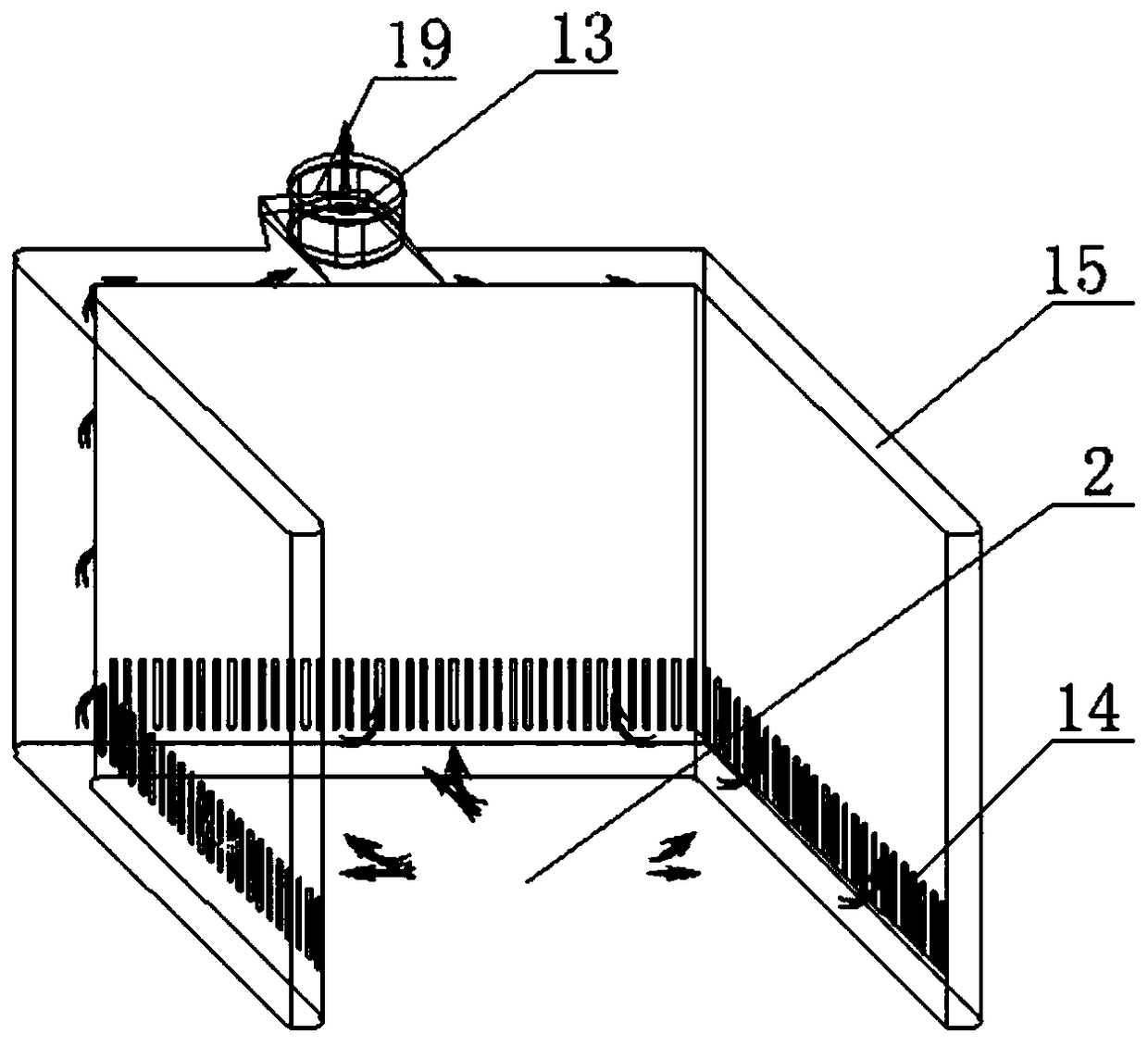

[0011] See figure 1 , image 3 , a 100-level clean gas detoxification cabinet, which includes a detoxification cabinet body 1, the detoxification cabinet body 1 includes an operating space 2, an operating table 3 is arranged in the operating space 2, and a plurality of diversion holes 4 are arranged on the operating table 3, The diversion hole 4 comprises a grille-shaped diversion hole 4-1 at the near end of the operating table 3 and a circular diversion hole at the far end of the operating table 3. The diversion hole 4-2 is connected to the exhaust outlet 13, and the operating table 3 is connected to the waste gas outlet. A liquid collection device 5 and a waste water discharge device (not shown in the figure), a precision clean filter system 6 is arranged in the operating space 2, and the clean filter system 6 includes a conical or trapezoidal air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com