Apparatus for maintaining internal cleanliness of interface unit

A technology of interface unit and cleanliness, which is applied in the field of wafer coating and developing production in the semiconductor industry, can solve the problems of internal cleanliness decline, waste of production time, energy consumption, etc., and achieve the effect of saving money, increasing production capacity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

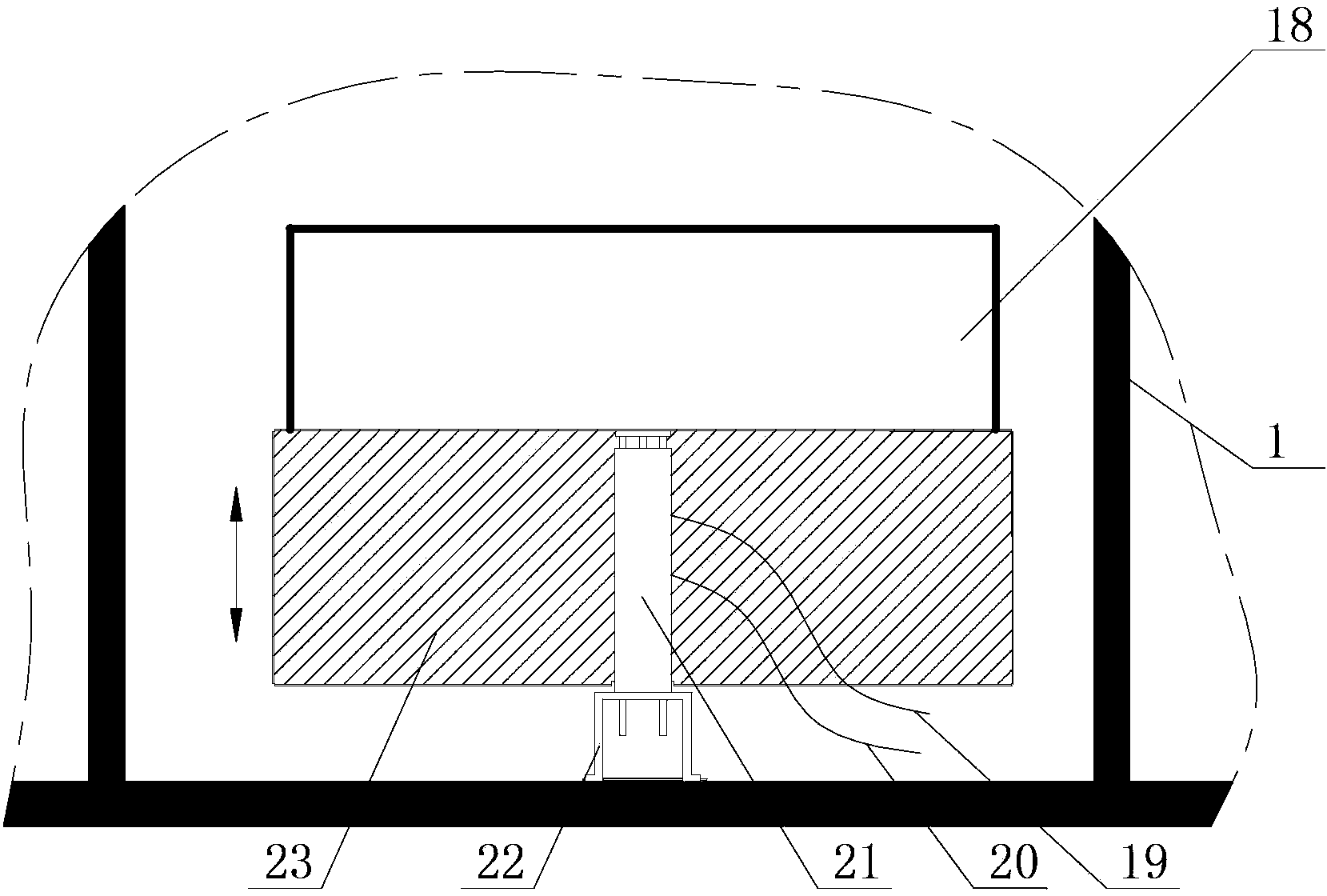

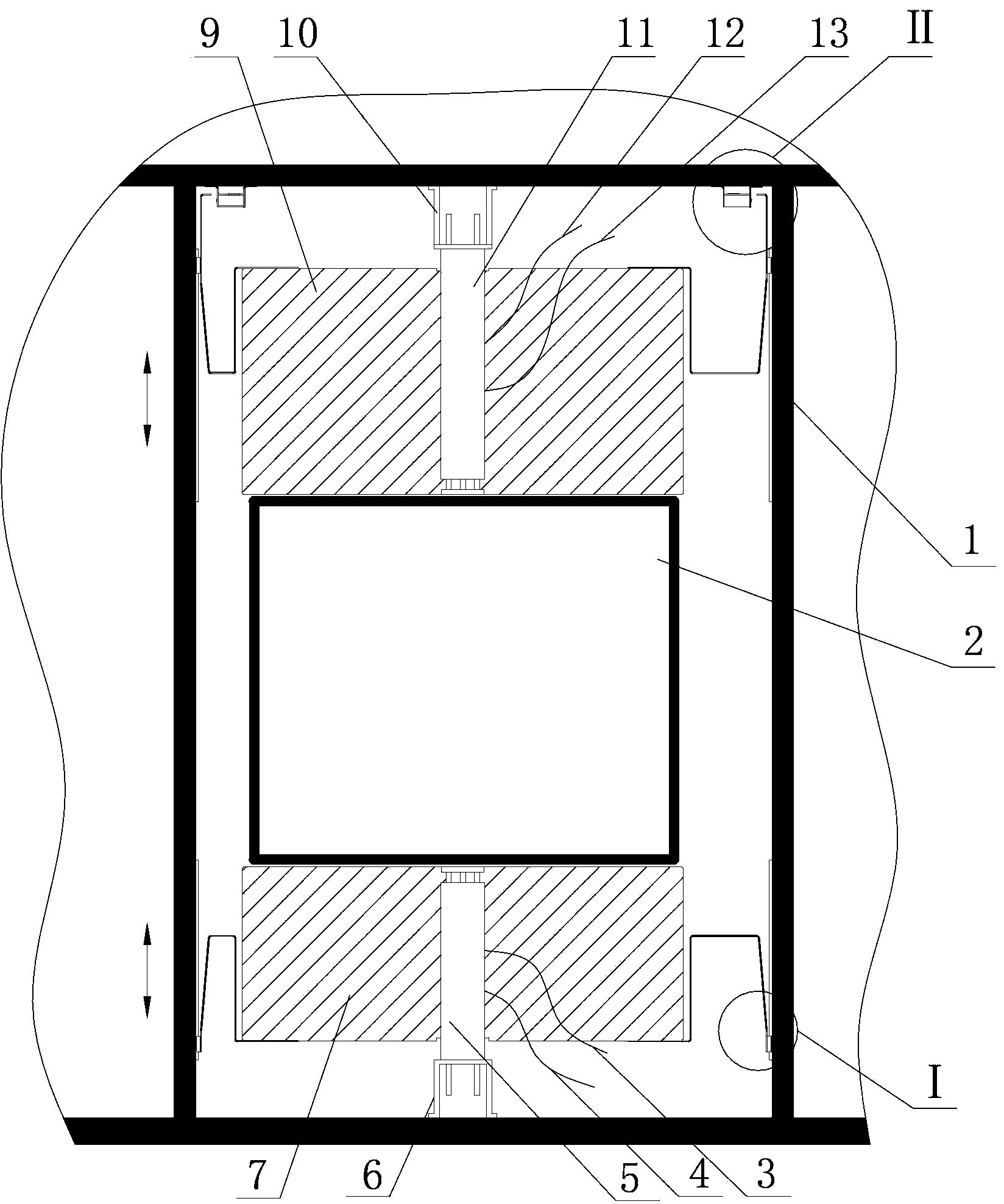

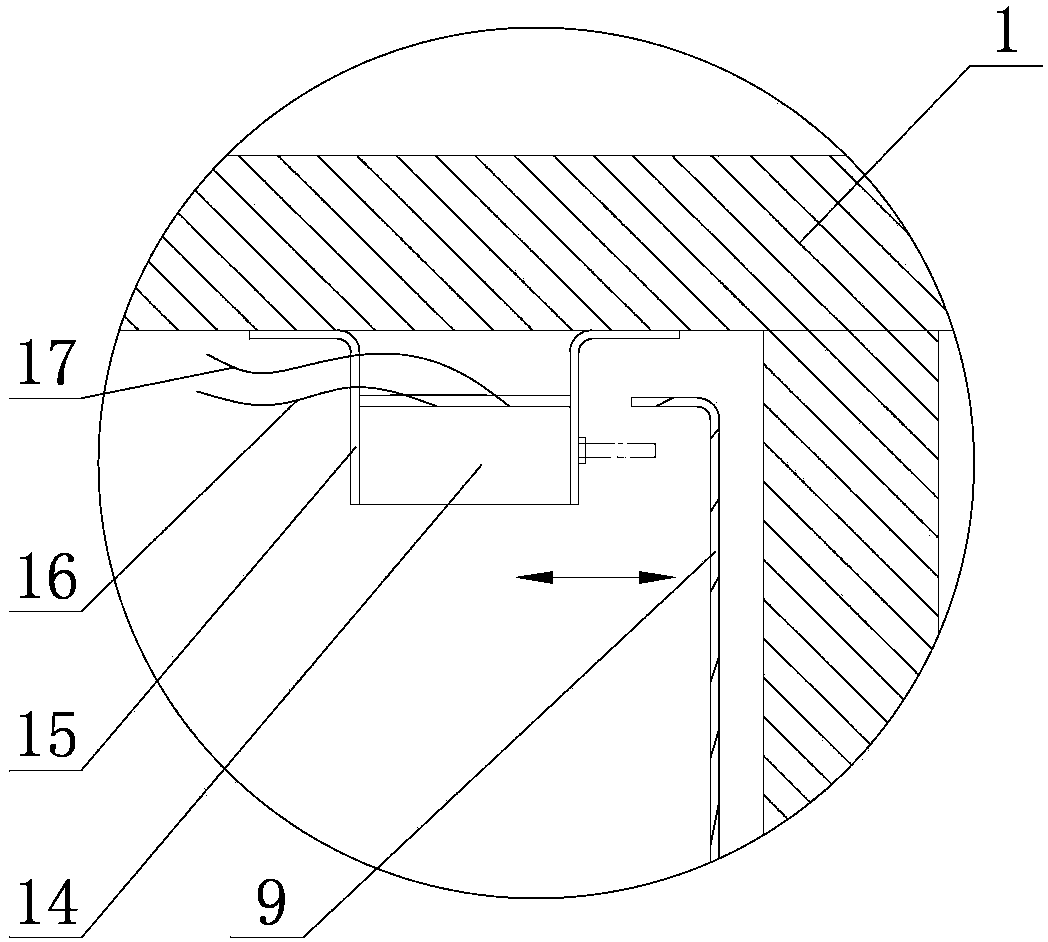

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] The present invention is arranged on the openings on both sides of the interface unit connected with TRACK and the lithography machine, and includes a shielding baffle and a driving device connected thereto, and the shielding baffle is driven by the driving device to close or open the interface unit and TRACK and the lithography machine For the connected opening, a sealing device is provided at the joint between the shielding baffle and the frame inner wall of the opening of the interface unit. The driving device is arranged on the inner wall of the frame 1 of the interface unit, and the driving device is connected with the TRACK host, and its action is controlled by the TRACK host. The driving device can adopt a cylinder device or a motor. The TRACK host is an existing technology.

[0022] like figure 1 As shown, the present invention is provided at the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com