Air filter and rectification device for semiconductor equipment

A rectifier and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of uneven air flow, influence of wafer process accuracy, etc., to ensure uniformity, save reprocessing time, improve The effect of process precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

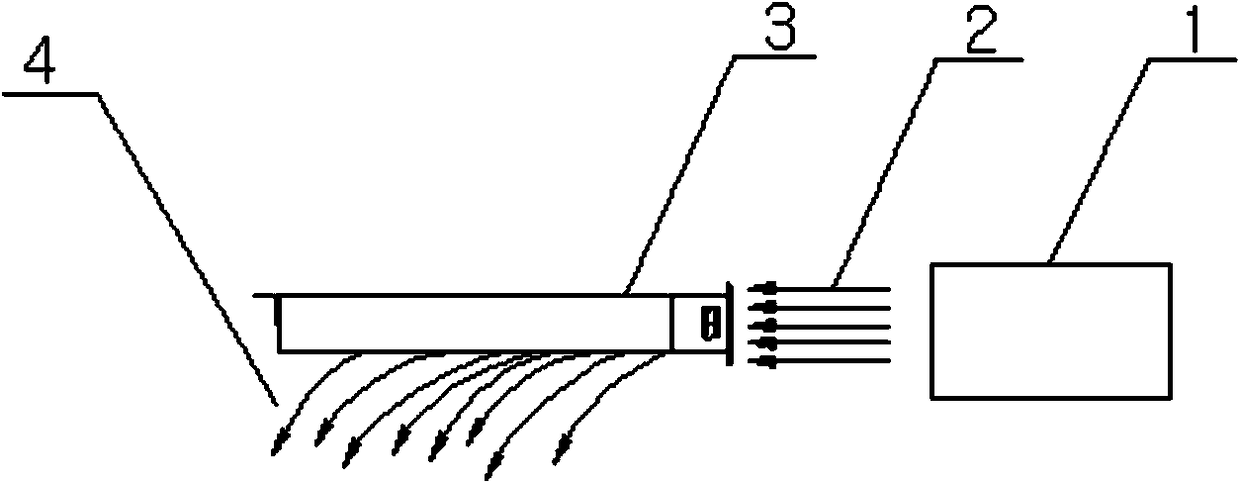

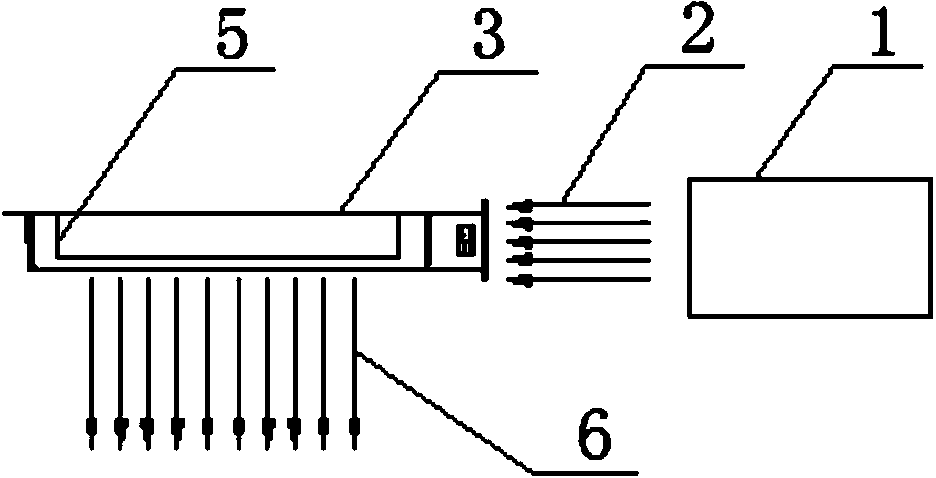

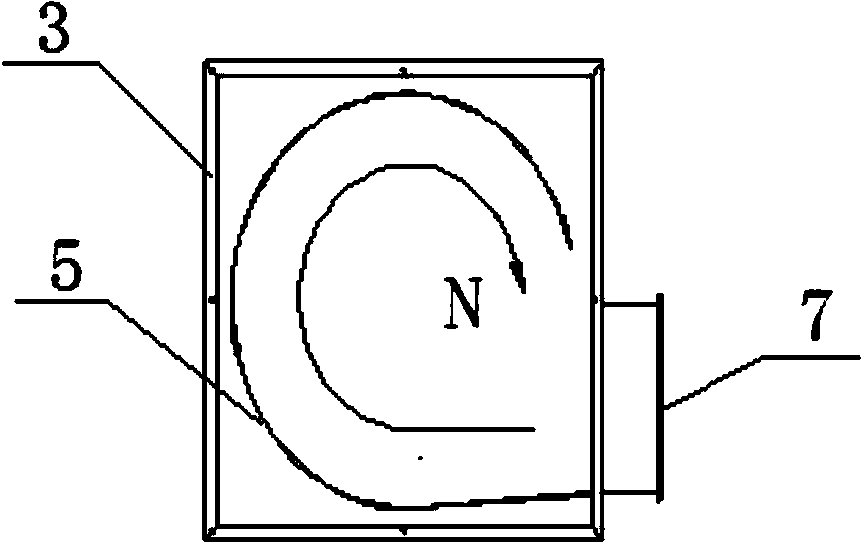

[0020] Such as figure 2 As shown, the present invention is installed on the side of the air supply system of semiconductor equipment, and is located between the air supply system 1 and the work area, including the air filter rectifier box 3 and the rectifier plate 5, wherein one side of the air filter rectifier box 3 is provided with The air inlet 7 of the air filter rectifier box corresponding to the air supply system 1, the bottom of the air filter rectifier box 3 is evenly distributed with a plurality of outlets of the air filter rectifier box. The rectifying plate 5 is vertically arranged in the air filtering rectifying box 3 , and its upper side is connected with the top of the filtering air rectifying box 3 . The uneven air flow provided by the air supply system 1 enters the air filter rectifier box 3 through the air inlet 7 of the air filter rectifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com