Single-sided double-point spot welding equipment

A kind of equipment and single-sided technology, applied in the field of single-sided double-point spot welding equipment, can solve problems such as tension loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

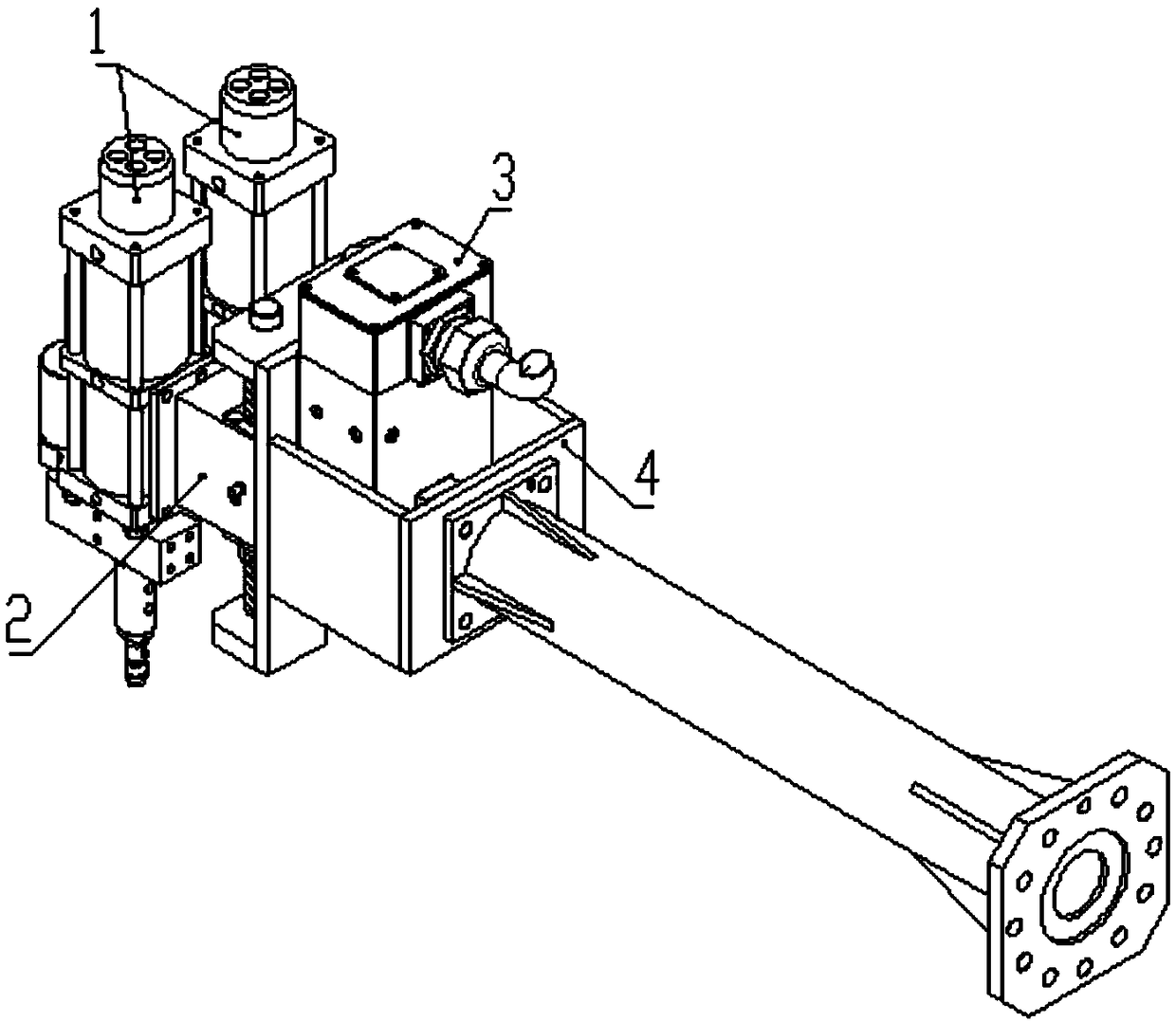

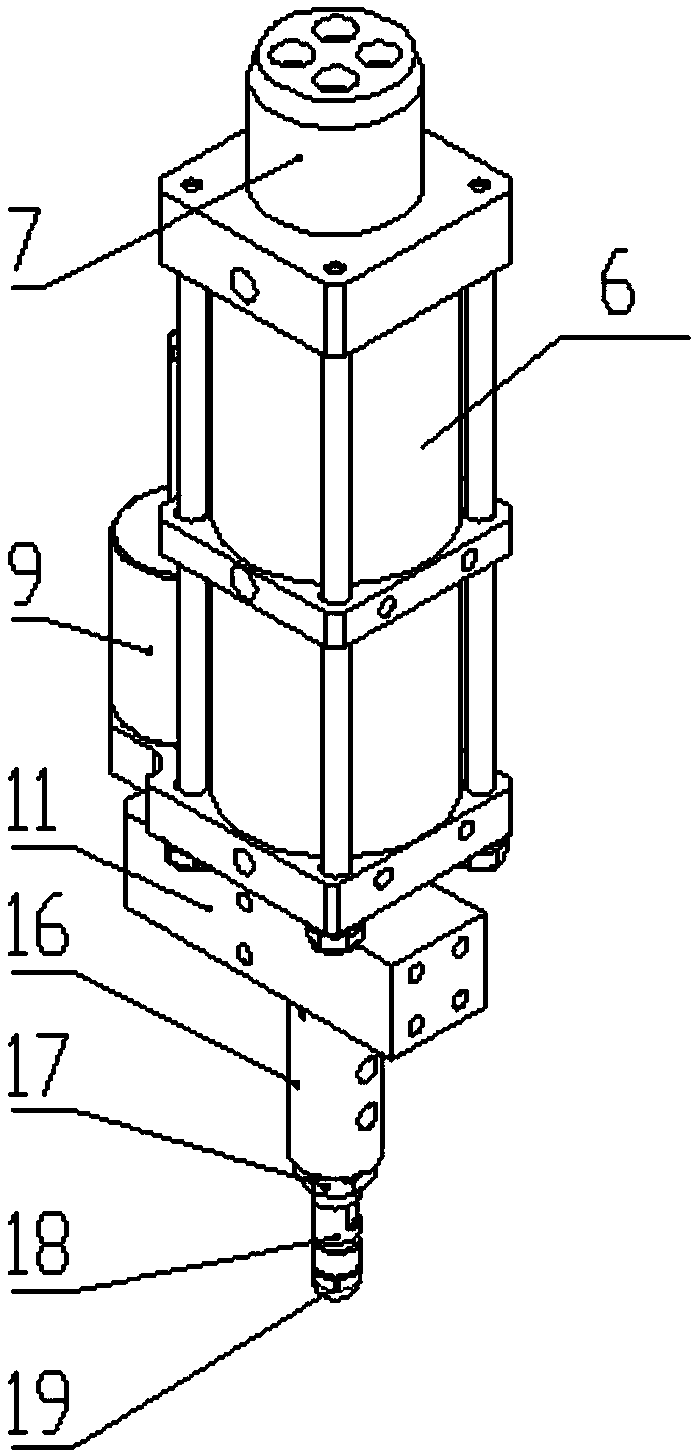

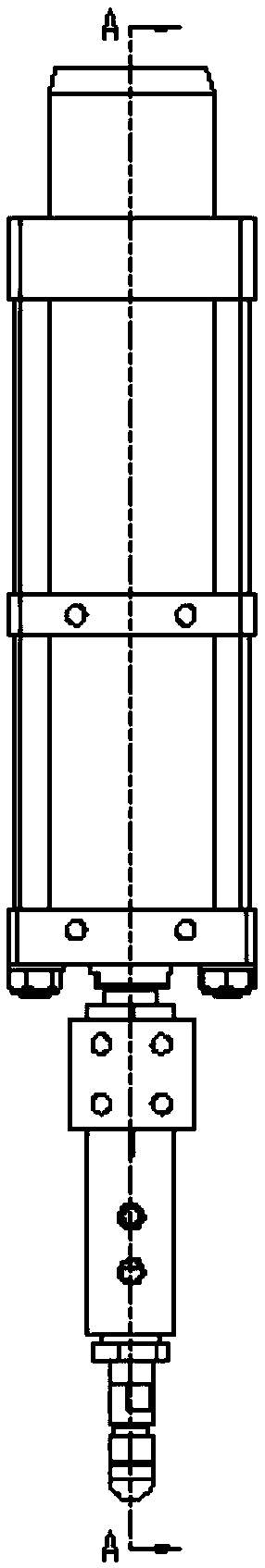

[0022] A single-sided double-spot spot welding equipment, which includes a mounting bracket 4, a welding mechanism 1 and a transformer assembly 3. The welding mechanism includes a welding mechanism mounting base 9, a driving mechanism and a welding gun body. The welding mechanism mounting base is floatingly mounted on At the front end of the mounting bracket, there are two sets of the driving mechanism and the welding torch main body. The driving mechanism is installed on the welding mechanism mounting seat to drive the welding torch main body to move up and down, and the transformer assembly is fixedly installed on the mounting bracket and electrically connected with the welding torch main body.

[0023] Further, an upper baffle 21 and a lower baffle 22 are fixedly installed at the front end of the mounting bracket. A floating guide rod 5 is installed on the upper and lower baffles, and a floating mounting seat 2 is sleeved on the floating guide rod. A spring 20 is sleeved betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com