Multi-specification button holing machine

A punching machine and multi-specification technology, applied in the field of clothing machinery, can solve the problems of low efficiency in the production chain, damage to clothes, equipment damage, etc., and achieve the effect of achieving diversity and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

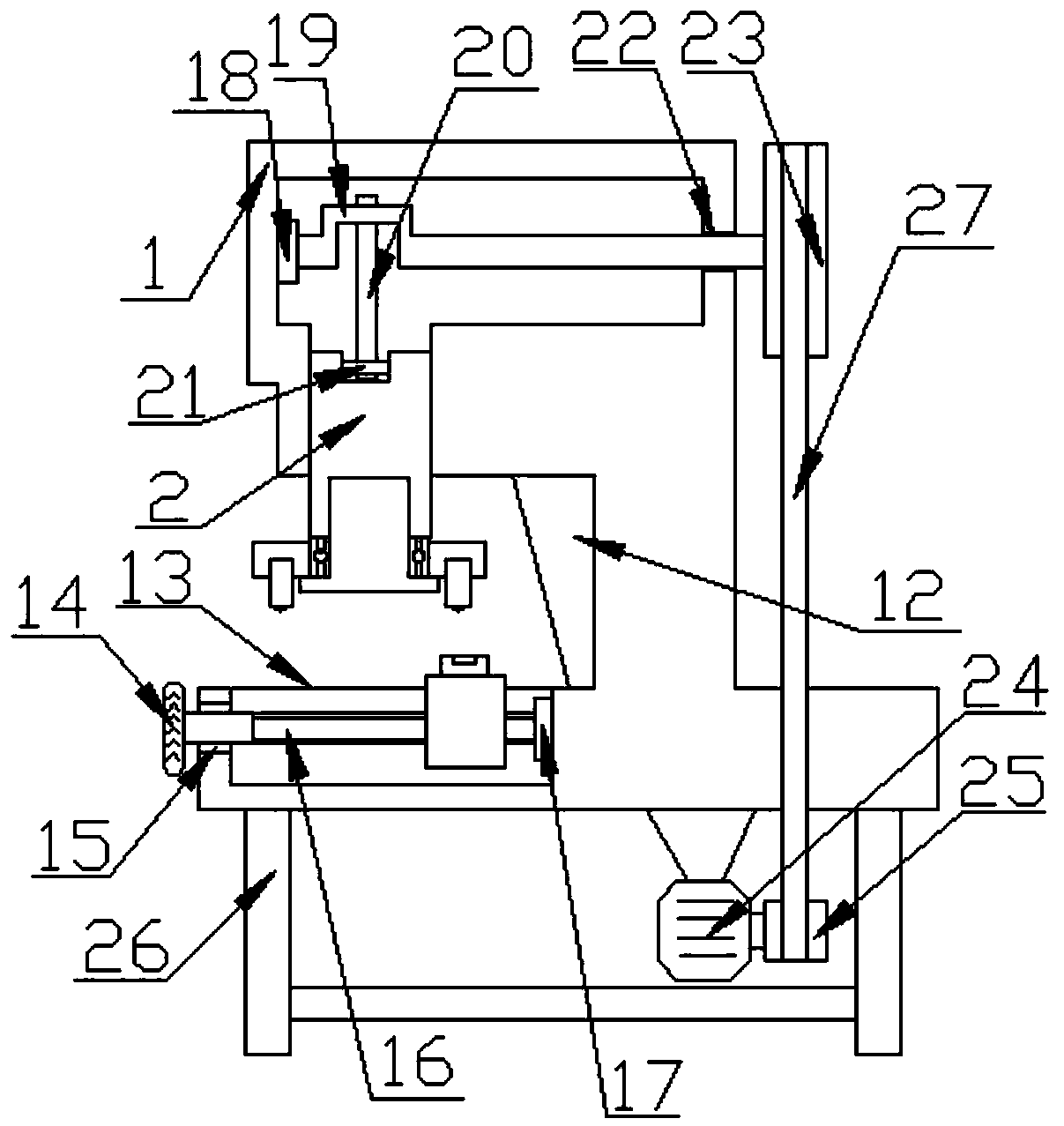

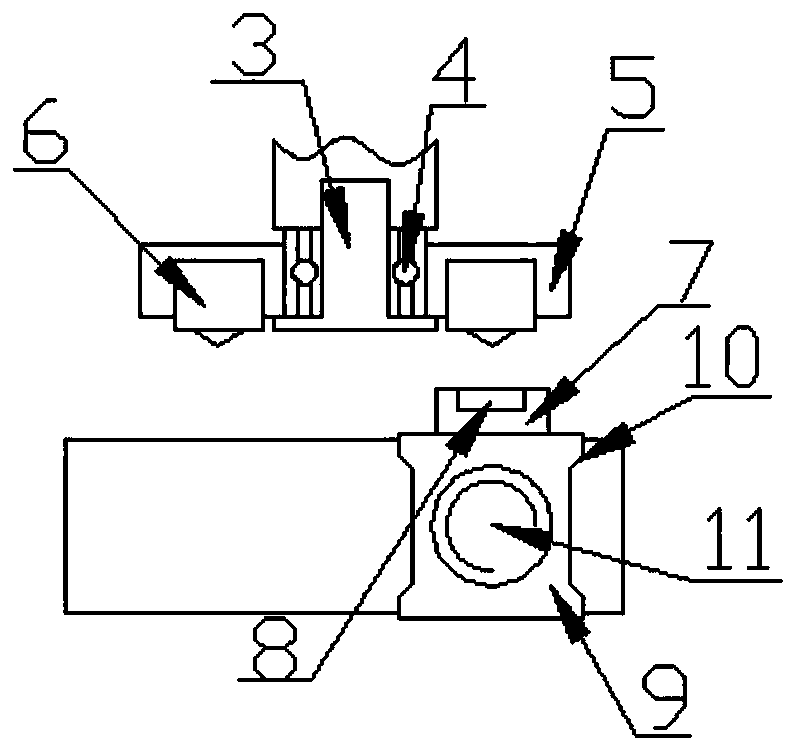

[0019] Such as Figure 1-2 As shown, the present invention provides a multi-standard buttonhole punching machine for garment production, comprising a buttonhole punching machine body 1, a piston 2 is arranged on one side of the buttonhole punching machine body 1, and a threaded sleeve is arranged on one end of the piston 2 Seat 3, one side of the threaded sleeve seat 3 is provided with a sleeve bearing 4, one side of the sleeve bearing 4 is provided with a punching pin fixing disc 5, and one side of the punching pin fixing disc 5 is provided with a grommet punching pin 6. One side of the buttonhole punching pin 6 is provided with a buttonhole punching seat 7, and the inside of the buttonhole punching seat 7 is provided with a buttonhole punching groove 8, and one side of the buttonhole punching groove 8 is provided with a moving slider 9, and the moving slider Both sides of block 9 are provided with moving slide rails 10, and one side of moving slide rails 10 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com