Sucking device, unstacking device and unstacking method

A technology of suction device and cargo stack, applied in the field of suction device, can solve the problems of low degree of automation and poor versatility, and achieve the effect of improving general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

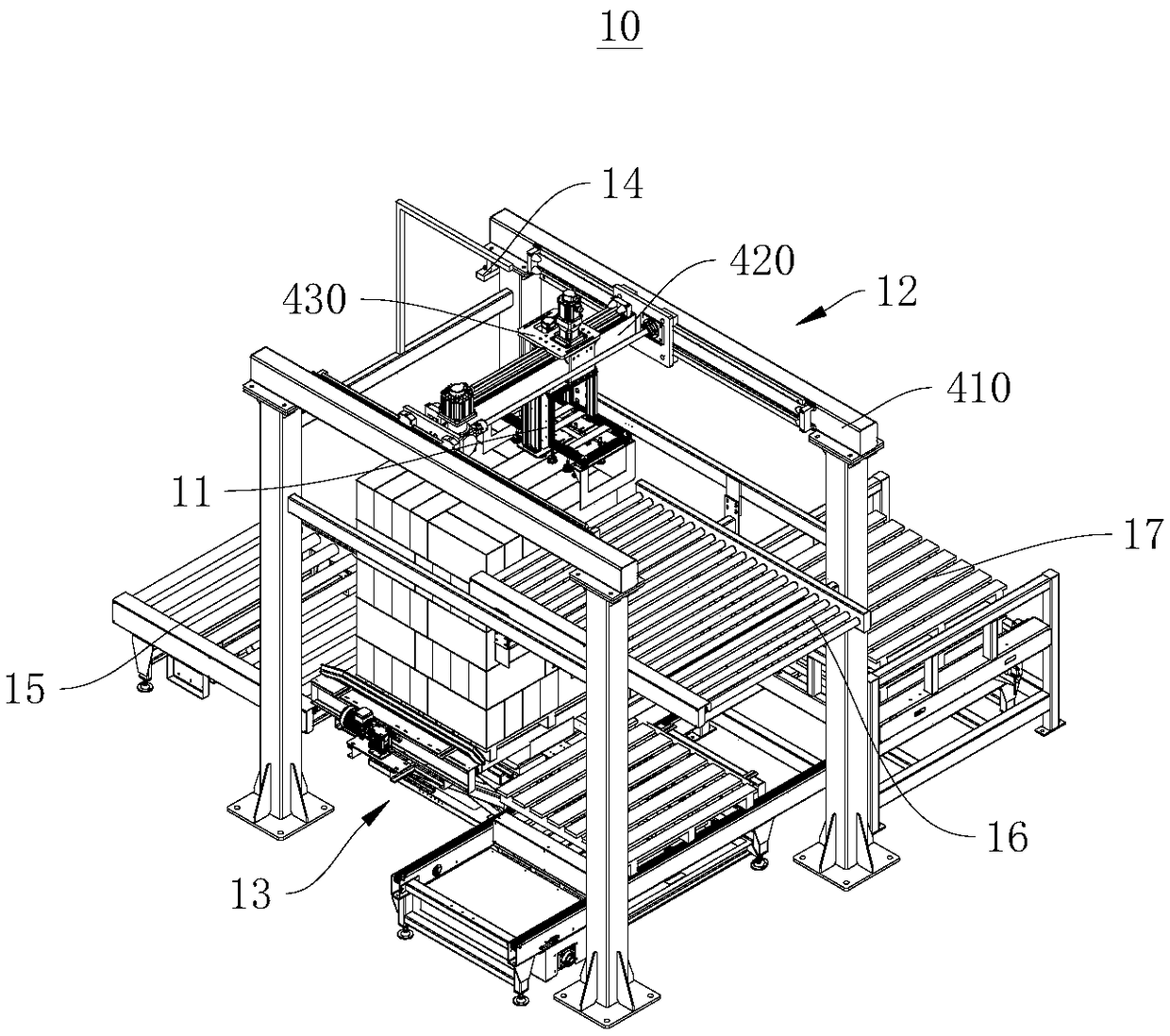

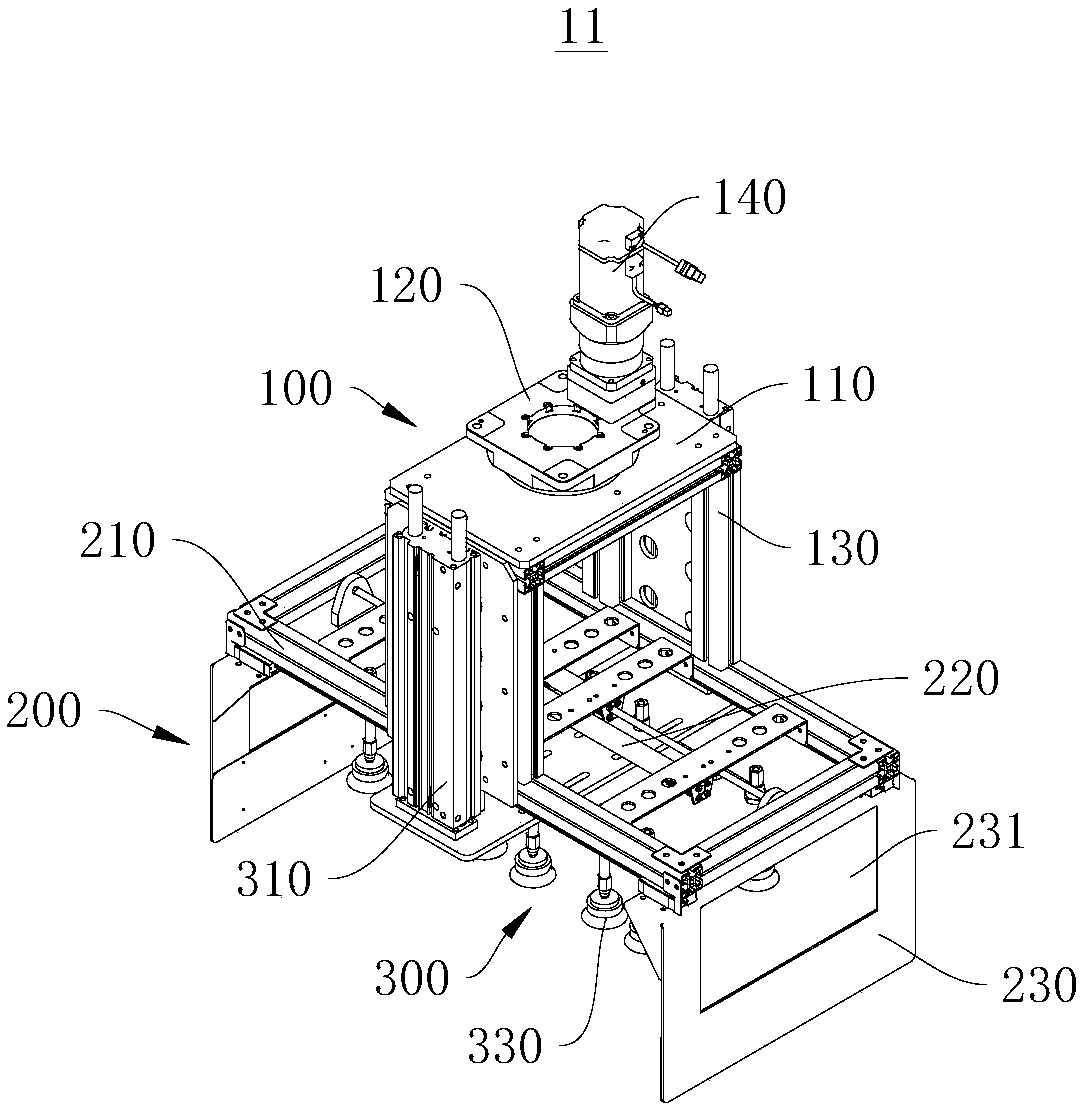

[0046] see figure 1 In this embodiment, a depalletizing device 10 is provided, which is used for sorting goods. That is, the depalletizing device 10 can sort the stacked goods into multiple goods, so as to facilitate the sorting and handling of the multiple goods. The unstacking device 10 can improve versatility, facilitate automation, and improve the efficiency of unstacking. Among them, stacked goods are also called goods stacks.

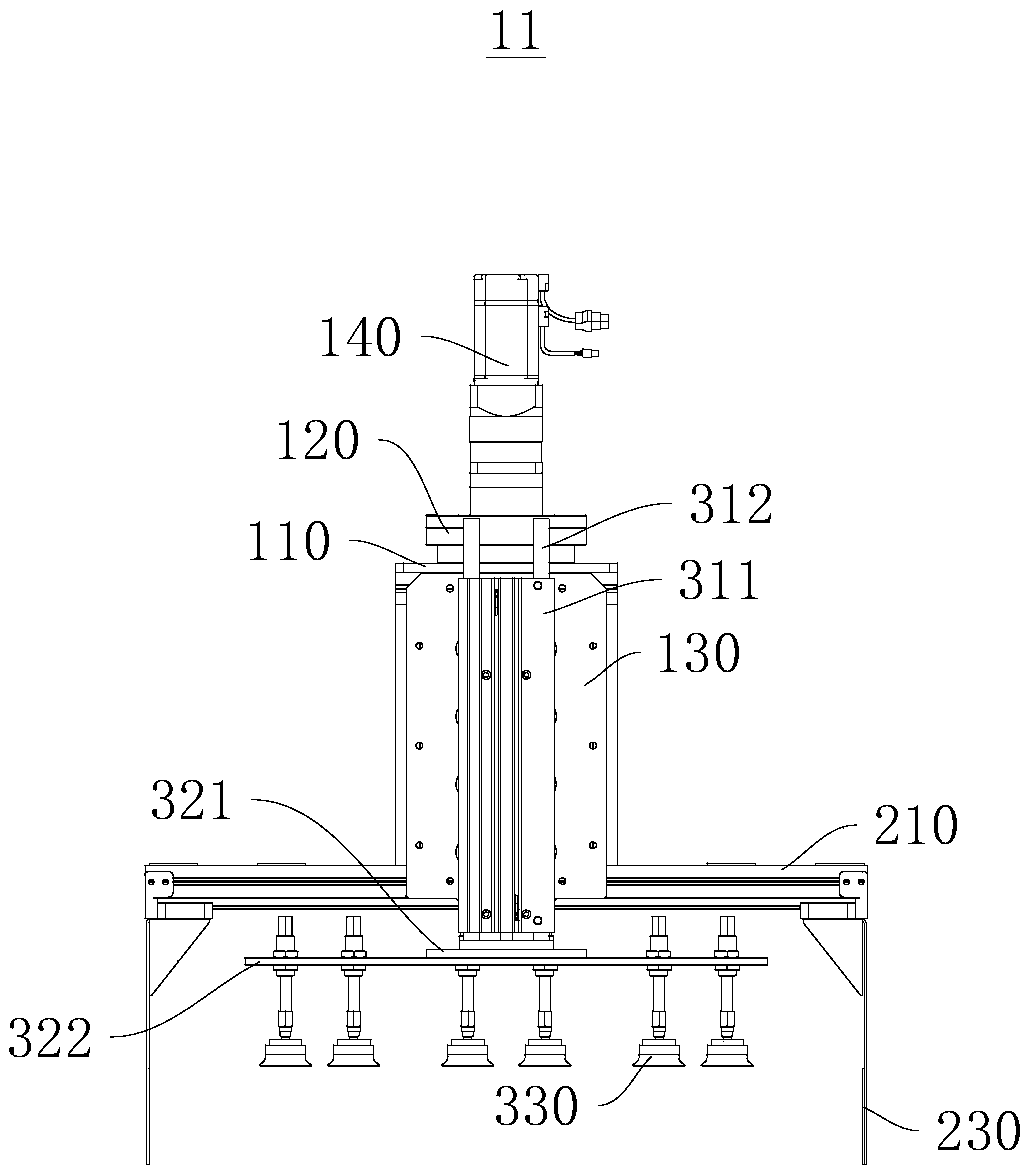

[0047] The unstacking device 10 includes a moving platform 12 , a suction device 11 and a lifting platform 13 . Wherein, the suction device 11 is connected to the moving platform 12, and the moving platform 12 can drive the suction device 11 to move, so that the suction device 11 sorts the goods from the top of the stacked goods. The lifting platform 13 is arranged at the bottom inside the moving platform 12, and the lifting platform 13 is used to carry the stacked goods, and can be used to lift the stacked goods to an appropriate height, so th...

no. 2 example

[0073] Please refer to figure 1 and Figure 7 , this embodiment provides a depalletizing method, which is applied to the depalletizing device 10 provided in the first embodiment. Moreover, the destacking method can improve versatility, facilitate automation, and improve the efficiency of destacking.

[0074] Among them, the unstacking methods include:

[0075] S1. The cargo stack input line 15 transports the cargo stack to the lifting platform 13 .

[0076] S2. The lifting platform 13 lifts the stack to a specified height.

[0077] S3. The visual identification device 14 identifies the position and direction of the upper stack.

[0078] S4. The control system controls the movement of the motion platform 12 and the suction device 11 according to the information collected by the visual recognition device 14 .

[0079] S5. The suction device 11 extracts the goods onto the goods output line 16 .

[0080] S6. Repeat the step S2 to the step S5 until the goods on the stack are ...

no. 3 example

[0083] Please refer to figure 1 and Figure 8 , this embodiment provides a depalletizing method, which is applied to the depalletizing device 10 provided in the first embodiment. Moreover, the destacking method can improve versatility, facilitate automation, and improve the efficiency of destacking.

[0084] Among them, the unstacking methods include:

[0085] S101 , the lifting platform 13 lifts the cargo and makes the cargo close to the suction device 11 .

[0086] That is, the goods are lifted to a certain height by the lifting platform 13, so that the goods are close to the suction device 11, and the suction device 11 can suck and sort the goods with a relatively small displacement.

[0087] S102. The moving platform 12 drives the suction device 11 to move above the goods.

[0088] Wherein, the joint movement of the first sliding structure 420 and the second sliding structure 430 drives the suction device 11 to move above the goods.

[0089] S103 , rotating the instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap