Method for adjusting car car-dumper car-pressing position and system

A dumper and vehicle technology, applied in the field of dumpers, can solve the problems that the dumper cannot automatically adjust the pressing position and the pressing efficiency is low, and achieve the effect of improving the pressing efficiency, ensuring accuracy, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

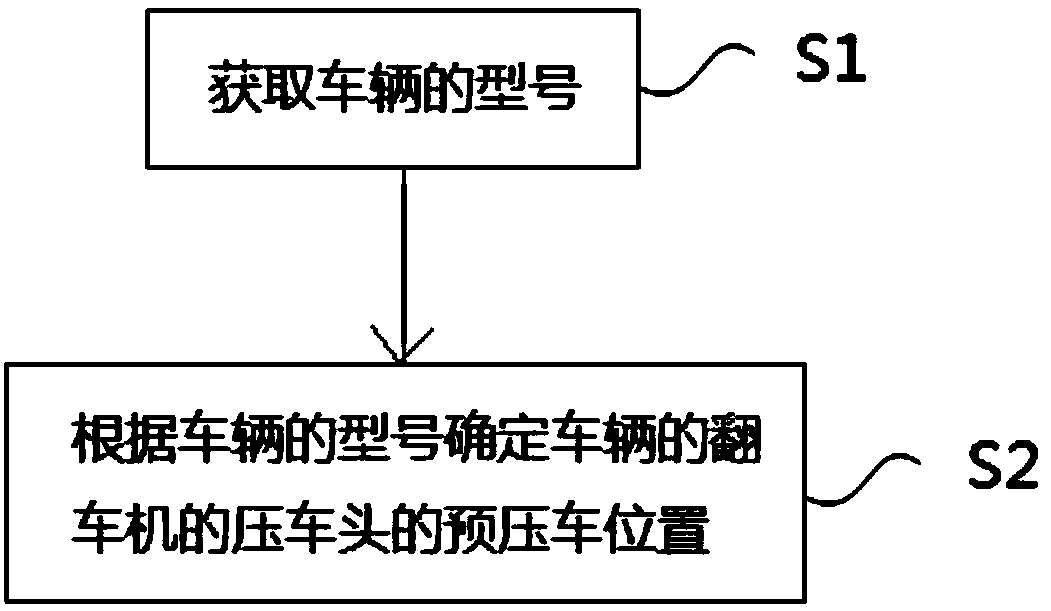

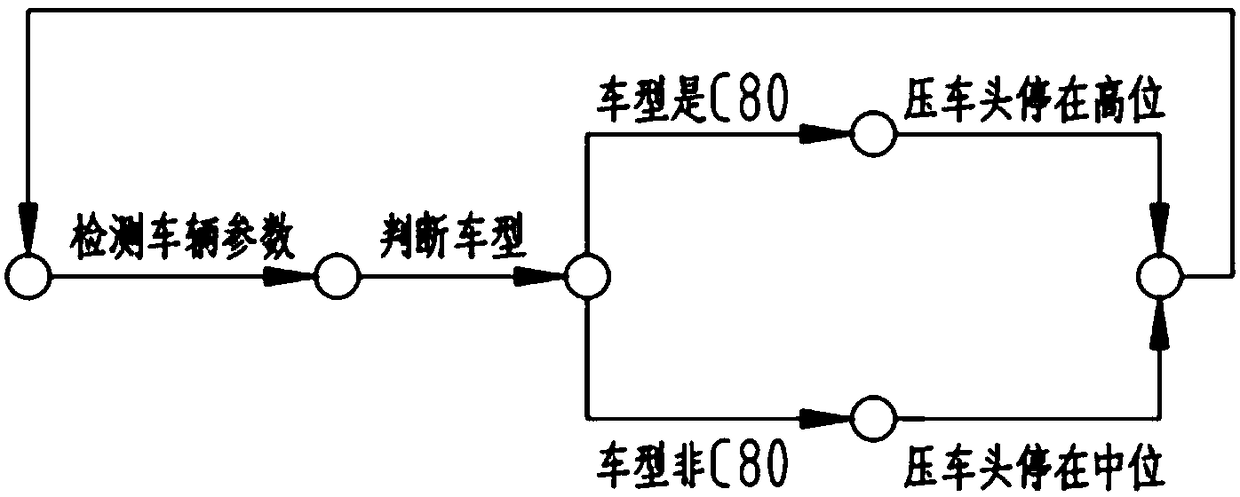

[0037] In this embodiment, a method for adjusting the pressing position of a vehicle tipper is provided, figure 1 It is a flowchart of a method for adjusting the pressing position of a vehicle dumper according to an embodiment of the present invention, such as figure 1 As shown, the process includes the following steps:

[0038] Step S1, obtain the model of the vehicle;

[0039] Step S2: Determine the pre-compression position of the head of the tipper of the vehicle according to the model of the vehicle.

[0040] Preferably, obtaining the model of the vehicle includes: collecting the wheel base of the vehicle; and determining the model of the vehicle according to the wheel base.

[0041] Specifically, collecting the wheelbase of the vehicle includes the following steps:

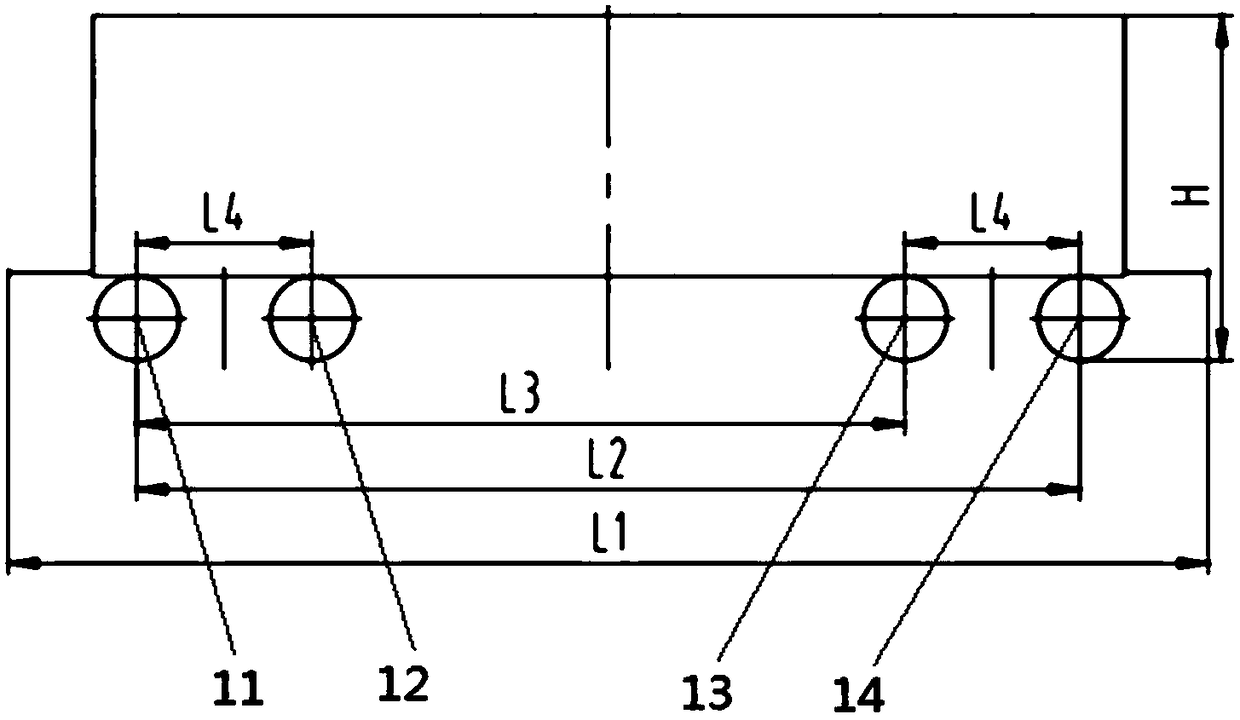

[0042] Step S21, measure the distance L4 between the first axle 11 and the second axle 12, if L4 is 1750mm, the vehicle belongs to the C60~C65 series gondola;

[0043] If L4 is 1830mm; proceed to the next judgment;

[00...

Embodiment 2

[0053] Such as Figure 4 As shown, different from Embodiment 1, if the dumped vehicle is a C65 series gondola, the head of the car is parked in a low position, and the low position is a position where the height from the ground is H4, and the H4 is greater than the H1.

[0054] Specifically, the height of the H5 is smaller than the height of the H6 and greater than the height of the H4. In this embodiment, the height of the H4 is equal to the height of the H2.

Embodiment 3

[0056] In this embodiment, there is provided a car dumper pressing system, which includes: a collection device and a processor; wherein, the collection device is used to obtain the model of the vehicle; the processor is used to The model of the vehicle collected by the collecting device determines the pre-compression position of the head of the car tipper of the vehicle.

[0057] Specifically, the collection device is also used to collect the wheelbase of the vehicle; the processor is also used to determine the model of the vehicle according to the wheelbase of the vehicle collected by the collection device.

[0058] Preferably, the collection device is arranged at the front end of the dumper.

[0059] In this embodiment, the car dumper compression system further includes: a hydraulic system; the hydraulic system receives an indication signal from the processor for indicating the position of the precompression car, and controls the car according to the indication signal The pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com