Wire winding device and leading wire drying system

A technology of a wire take-up device and a mounting frame, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve problems such as poor anti-failure ability, and achieve the effect of improving anti-failure ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

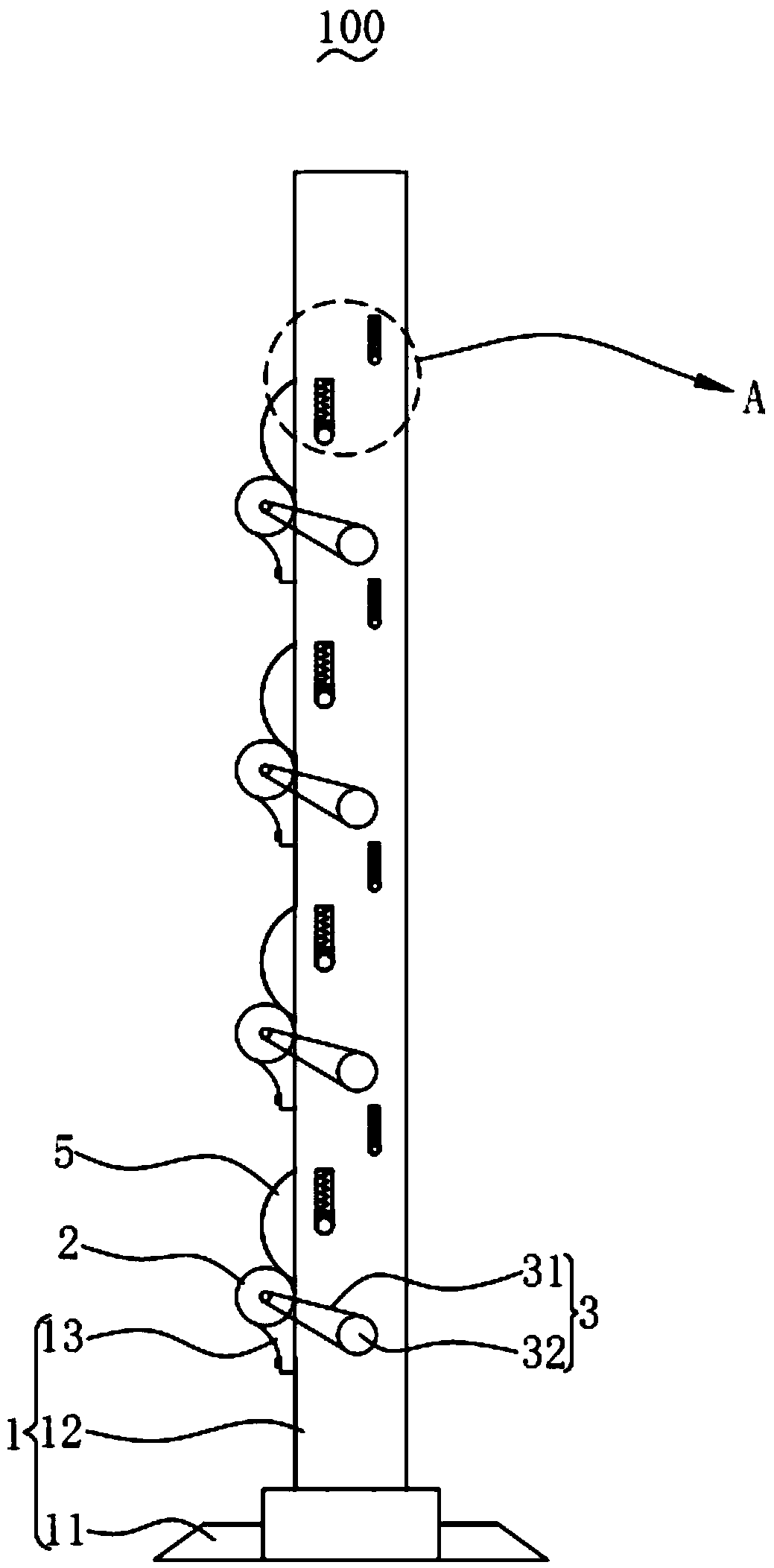

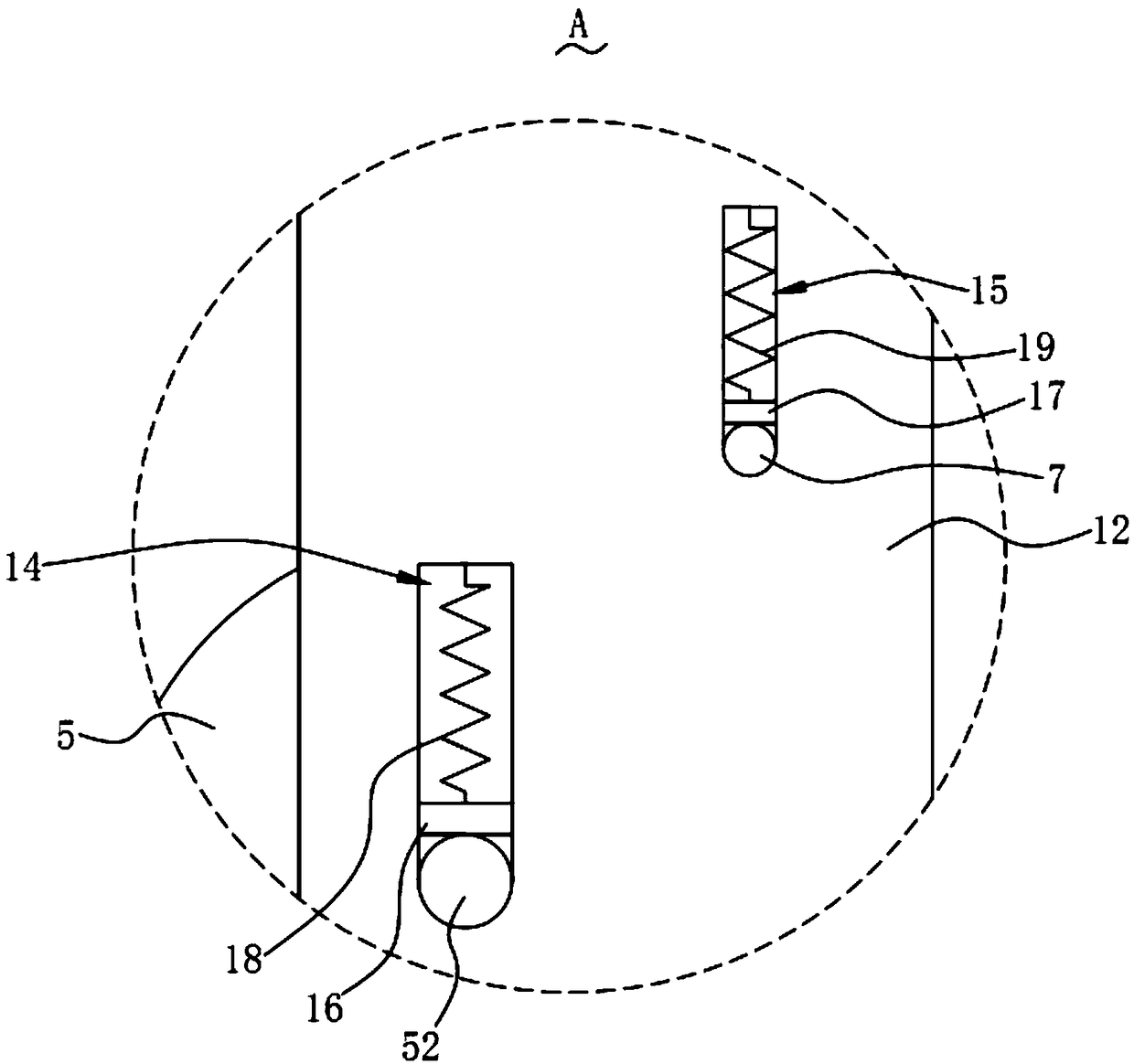

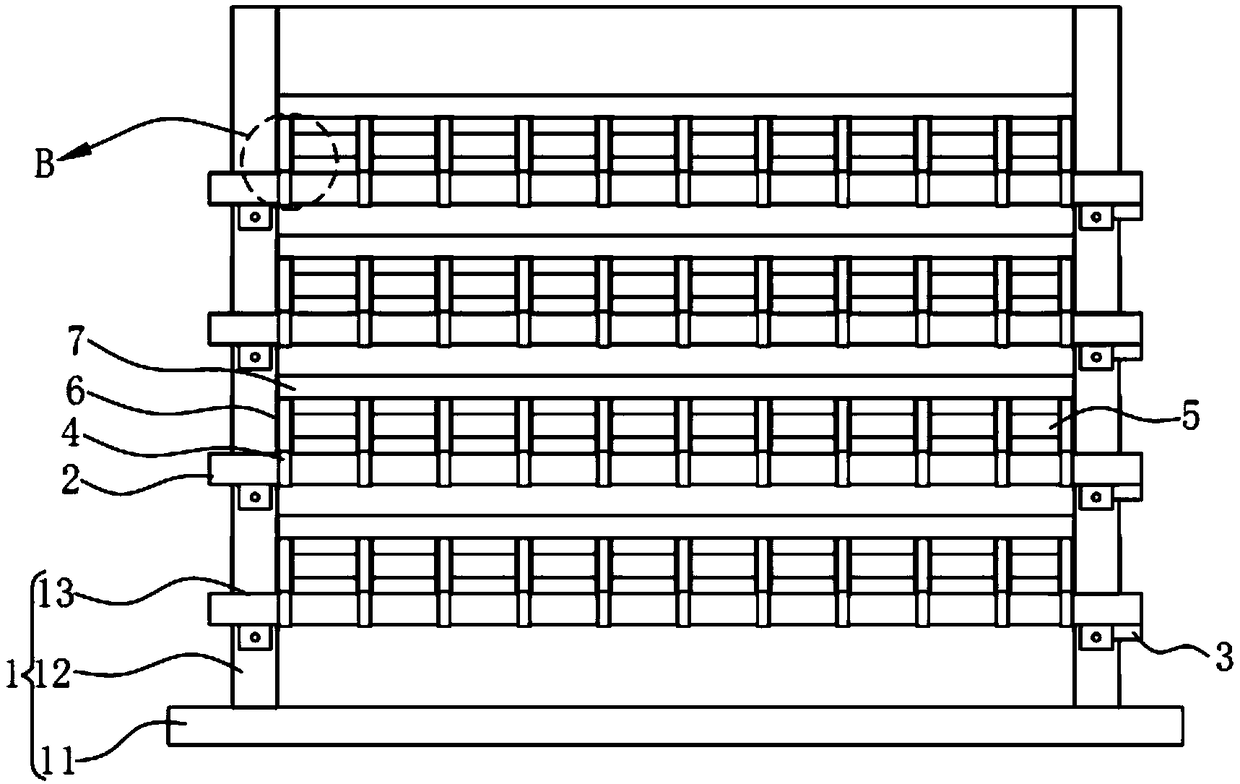

[0045] Please refer to Figure 1-4 , in one embodiment of the present invention, the wire take-up device 100 includes:

[0046] Mounting frame 1;

[0047] A drive shaft 2, the drive shaft 2 is rotationally connected with the installation frame 1;

[0048] A drive assembly 3, the drive assembly 3 is used to drive the drive shaft 2 to rotate;

[0049] A plurality of embossing wheels 4, and the embossing wheels 4 are arranged around the drive shaft 2;

[0050] The bobbin 5 is rotatably connected to the mounting frame 1;

[0051] A plurality of rotating rings 6, the rotating rings 6 are arranged around the winding shaft 5, and the first ends of two adjacent rotating rings 6 clamp an embossing wheel 4;

[0052] Driven shaft 7, driven shaft 7 is rotationally connected with mounting frame 1, and driven shaft 7 abuts against the second end of rotating ring 6; wherein, drive shaft 2, drive assembly 3, winding shaft 5 and driven shaft 7 equal in number.

[0053]The wire take-up de...

no. 2 example

[0065] Please refer to Figure 7-9 Based on the wire take-up device 100 provided in the first embodiment of the present invention, another wire take-up device 101 provided in the second embodiment of the present invention is different in that the wire take-up device 101 also includes a spare shaft 8 and Switch frame 9, switch frame 9 comprises the first frame body 91, the second frame body 92, the 3rd frame body 93 and the 4th frame body 94, the second frame body 92 and the 3rd frame body 93 are arranged at the first At the two ends of the frame body 91, one end of the fourth frame body 94 runs through the mounting frame 1, and the other end of the fourth frame body 94 is connected with the first frame body 91, and the fourth frame body 94 is set away from the second frame body 92. The second frame body 92 is inserted into the winding shaft 5 , and the third frame body 93 is inserted into the spare shaft 8 .

[0066] Thereby it is convenient to switch when the winding shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com