Automatic reset car arrester for cage

A technology of automatic reset and car arrester, which is applied to lifting equipment, transportation and packaging in mines, can solve the problems of car arrester operation is not simple enough, takes up a large space, and maintenance is complicated, and achieves a simple and easy overall structure , Occupying a small space in the tank, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, and the embodiments of the present invention include but are not limited to the following examples.

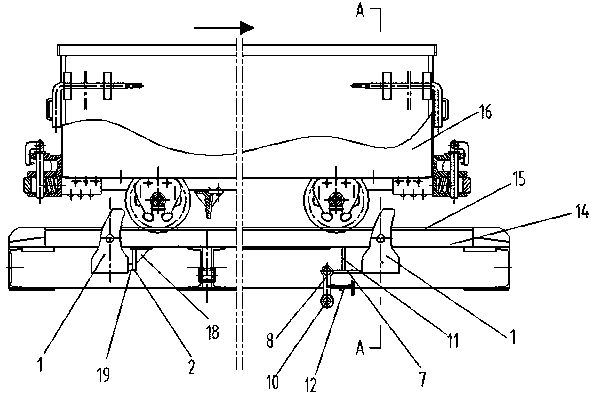

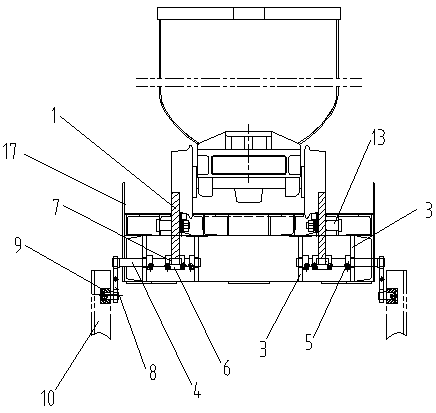

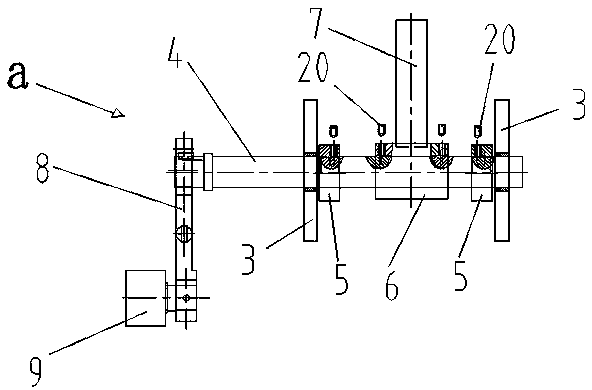

[0022] Such as Figures 1 to 5 shown. The invention provides a cage automatic reset car stopper, which comprises a left tumbler car stop block 1, a left vertical limit plate 2, a right side tumbler car stop block 1 and a right track sliding mechanism, and the right track slides The mechanism includes a guide rail 10 and a right side sliding mechanism a, and the right side sliding mechanism a includes a guide wheel 9, a swing member 8, a rotating shaft 4, a stop ring I5, a stop ring II6, a horizontal limit plate 7 and a support plate 3; A pin hole is provided on the upper front of the tumbler block 1, preferably a sleeve is fixed in the pin hole, then the pin 13 is slip-fitted through the sleeve, and finally both ends of the pin 13 are fixedly connected to the cage chas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap