Double-lever seven-section telescopic boom of crane

A telescopic boom and crane technology, applied in cranes and other directions, can solve the problems of high technical difficulty and manufacturing cost, the inability of the seven-section boom to extend and retract synchronously, and the low working strength and amplitude, so as to improve the working height and working range, reduce the Technical difficulty and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings:

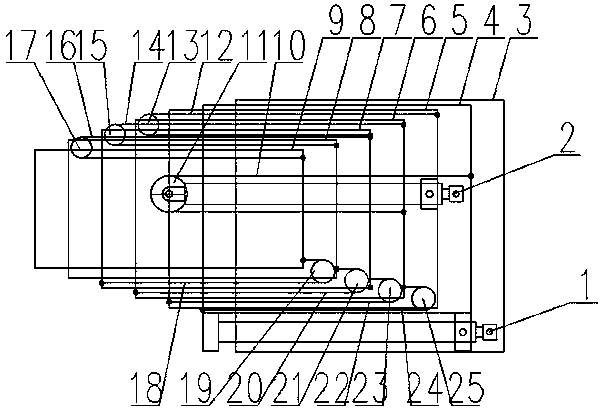

[0018] As shown in the figure, a double-bar seven-section telescopic boom of a crane includes telescopic cylinder I1, telescopic cylinder II2, one-section boom 3, two-section boom 4, three-section boom 5, four-section boom 6, and five-section boom. Section boom 7, six-section boom 8, seven-section boom 9, four-section boom outrigger rope row 10, four-section boom outrigger pulley block 11, five-section boom outrigger rope row 12, five-section boom outrigger pulley 13, six-section boom Arm extension arm rope row 14, six-section arm extension arm pulley block 15, seven-section arm extension arm rope row 16, seven-section arm extension arm pulley block 17, seven-section arm retraction arm rope row 18, seven-section arm extension arm pulley block 19, six Section arm retractable arm rope row 20, six section arm re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com