Lifting device for building materials

A technology for construction and materials, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of reducing construction efficiency, physical strength, falling, etc., and achieve the effect of reducing construction safety accidents, reducing labor intensity, and ensuring physical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

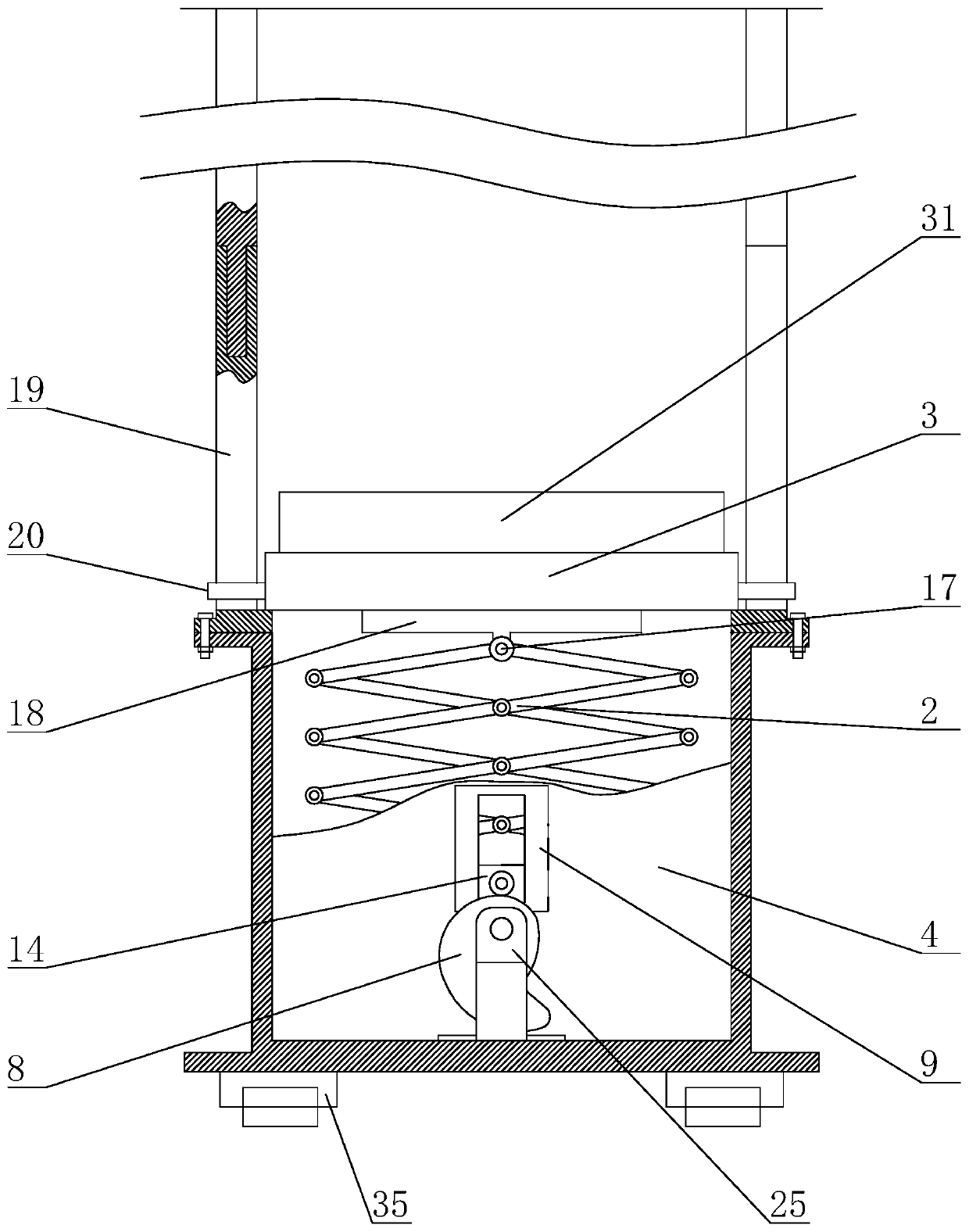

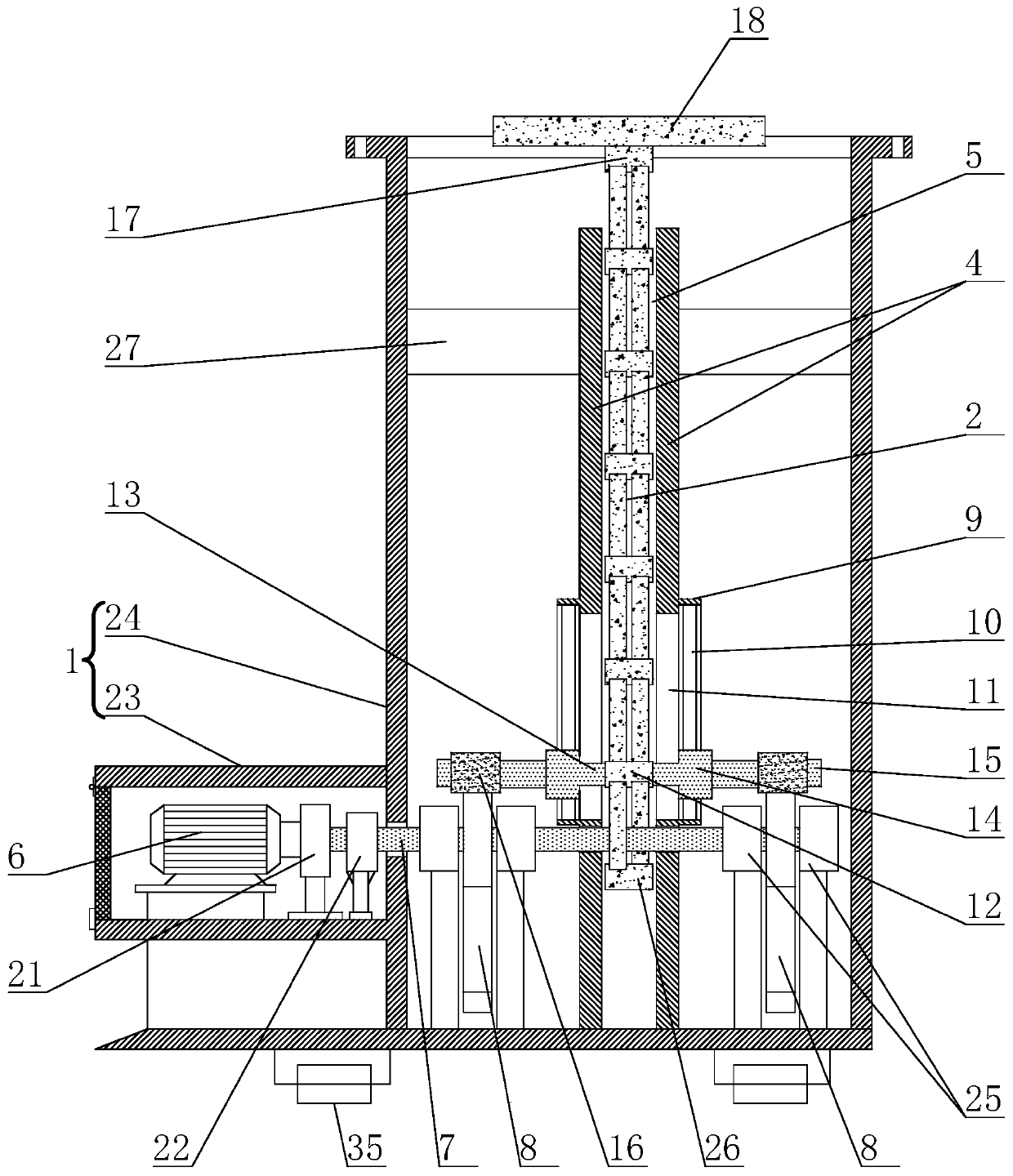

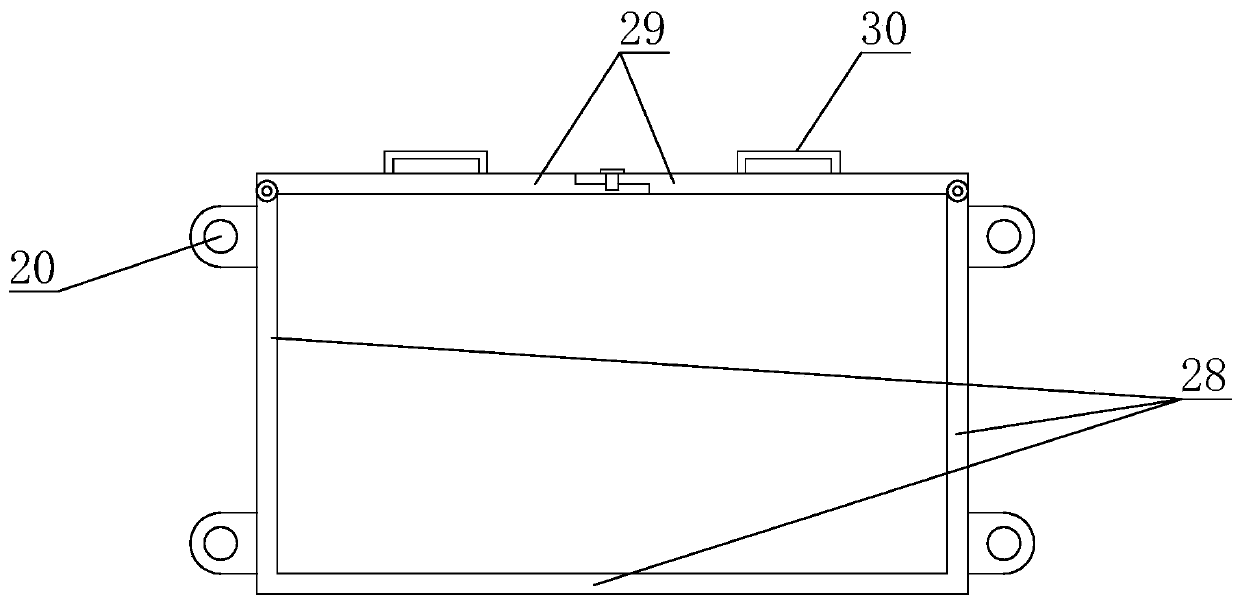

[0031] The present invention is a material lifting device for construction. The main structure includes a housing 1, a driving device assembly, a scissor lift mechanism 2, a guiding mechanism and a load-bearing plate 3. The housing 1 is an iron housing 1 or wooden case 1. The driving device assembly and the scissor lift platform mechanism 2 are all arranged in the housing 1; the housing 1 is provided with two position-limiting guide plates 4, the position-limiting guide plates 4 are steel plates, and the two A lifting platform movable chamber 5 is arranged between the limit guide plates 4, and the scissor-type lifting platform mechanism 2 is arranged in the lifting platform movable chamber 5, and the width of the lifting platform movable chamber 5 is slightly larger than that of the scissor-type lifting platform mechanism 2. Thickness, when the scissor lift mechanism 2 is contracted, the scissor lift mechanism 2 can be completely shrunk into the movable chamber 5 of the lift, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap