Pedestrian temporary steel bridge and micro steel pipe pile connecting structure and construction method thereof

A technology of connecting structures and micro-piles, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inconvenient transition and repeated use, isolated shops, inconvenience, etc., meet the requirements of safe and reliable pedestrian traffic, and save construction measures The effect of cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

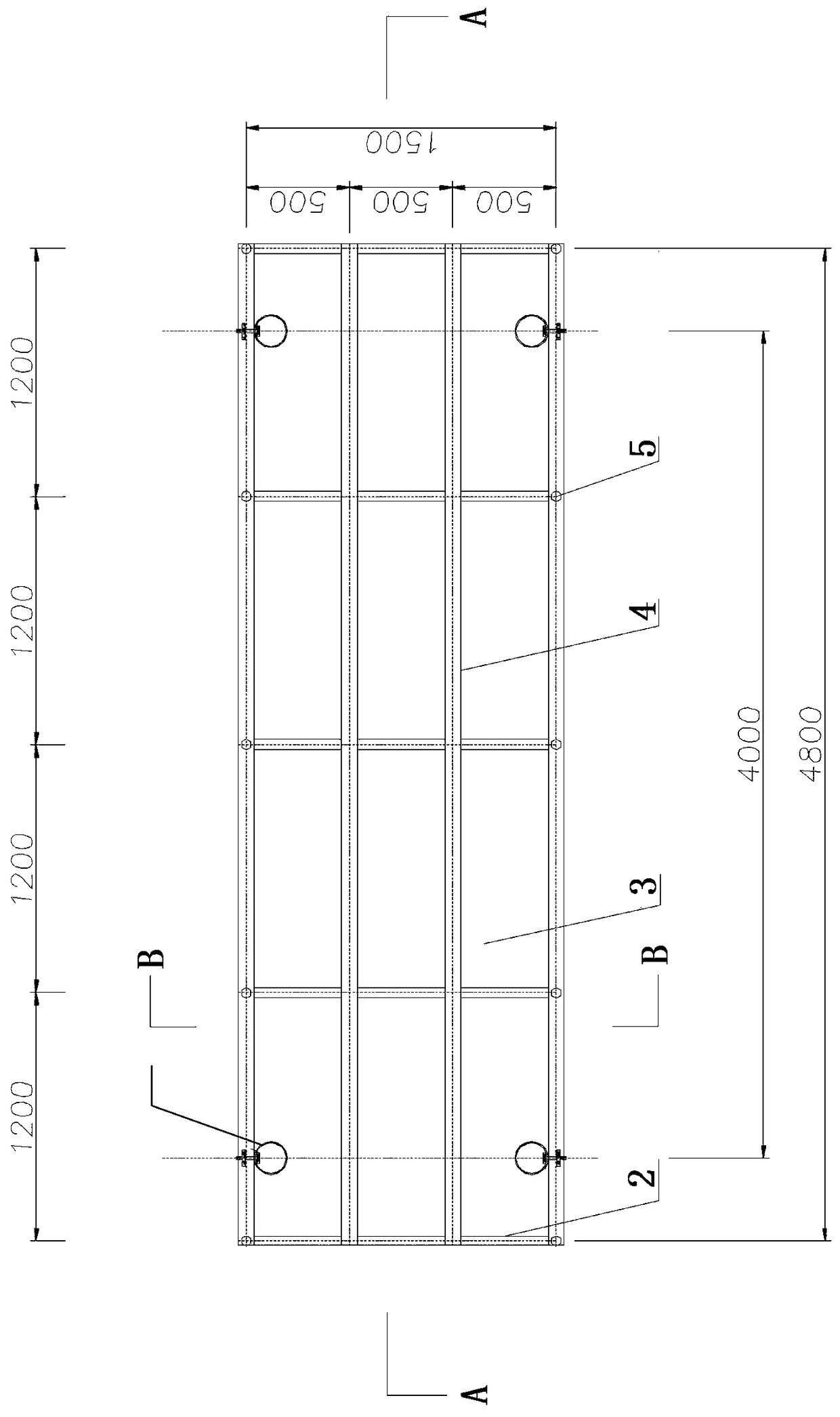

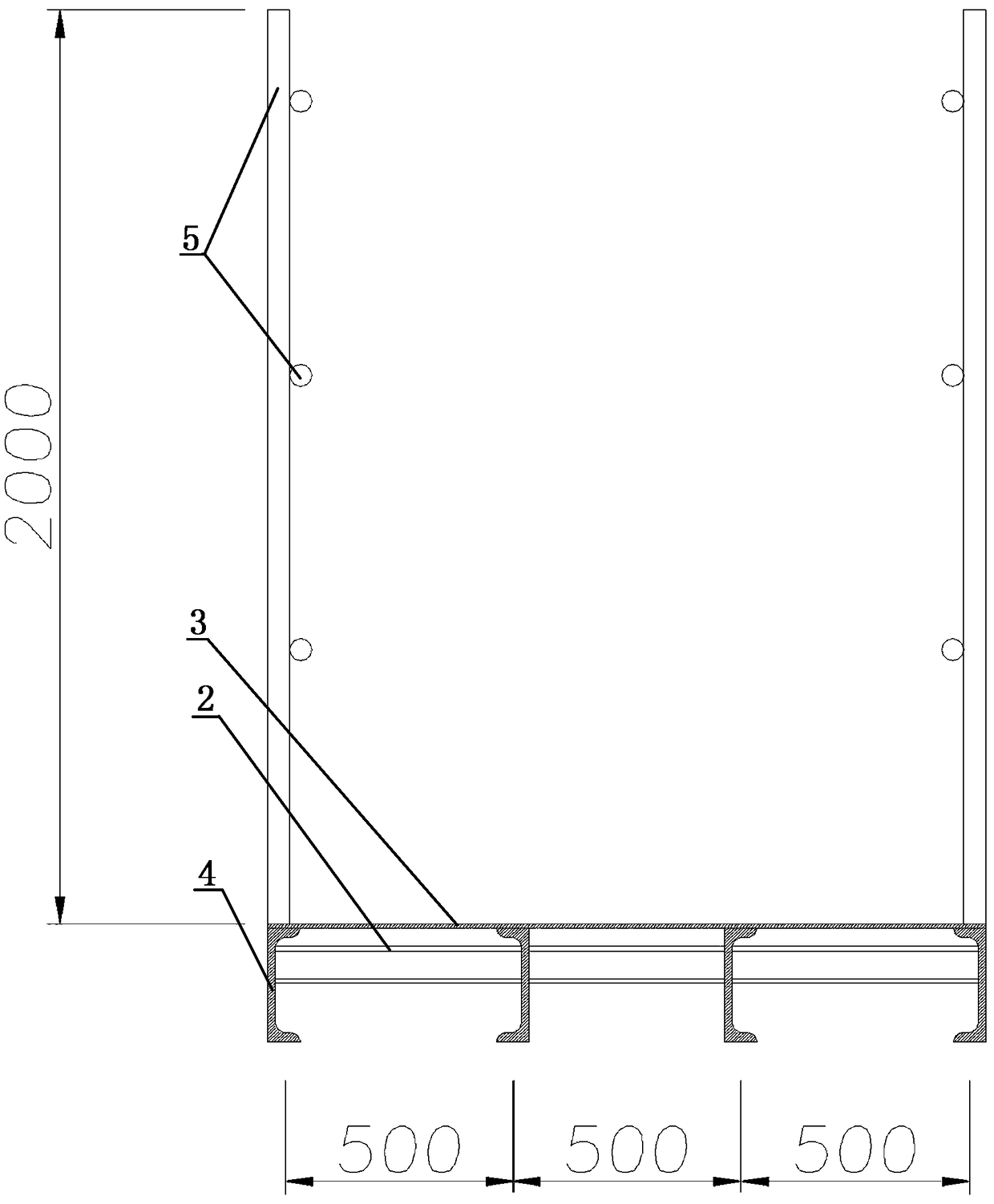

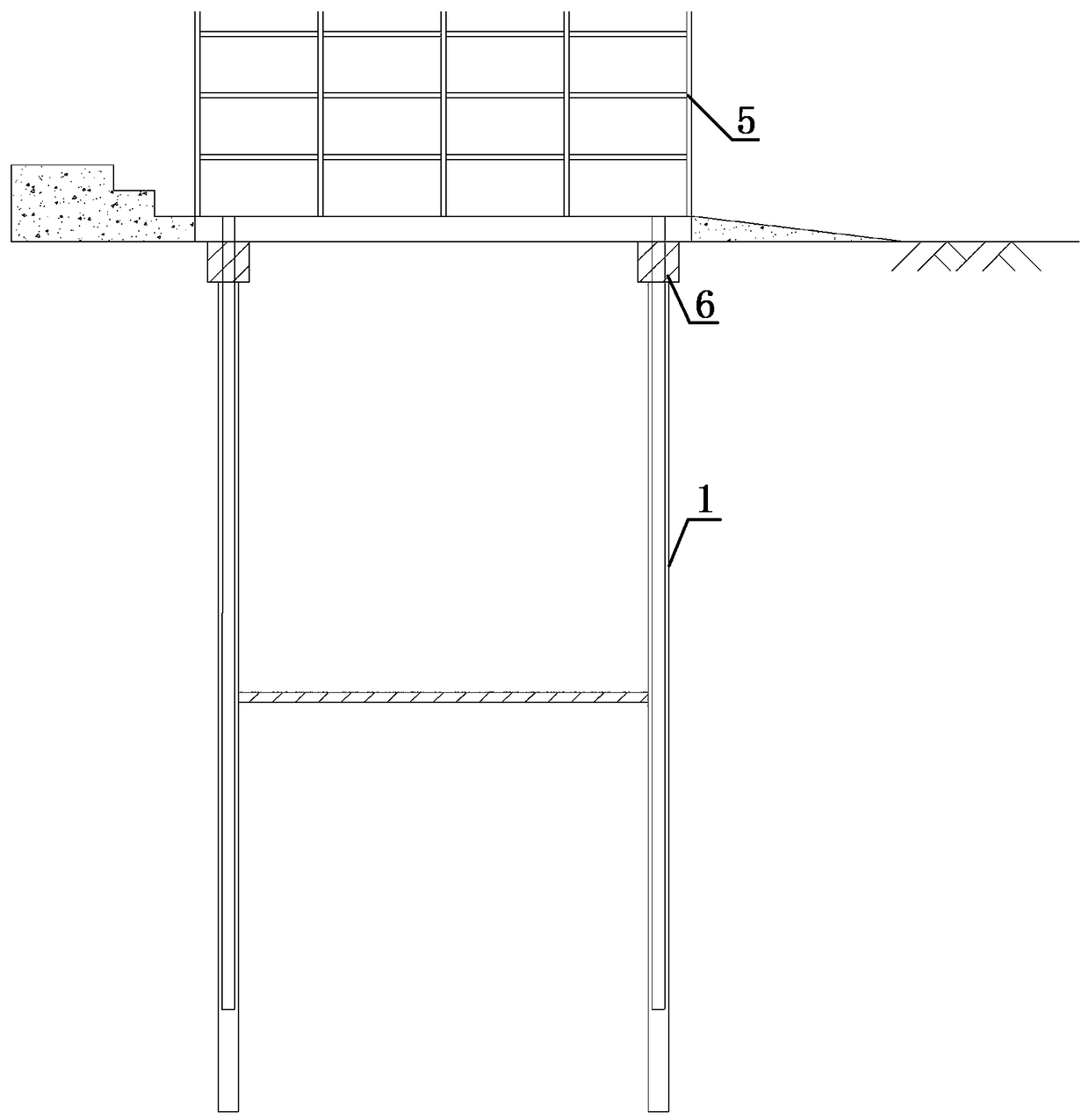

[0020] Such as Figure 1-3 As shown, a pedestrian steel temporary bridge and steel pipe micro pile connection structure and its construction method, including steel bridge frame bracing welded by longitudinal channel steel 2 and transverse channel steel 4, the surface of the steel bridge frame bracing is fixed with anti-skid steel plate 3. The two ends of the steel bridge frame brace are fixed by bolts and micro piles 1, and steel pipe guardrails 5 are arranged on both sides of the steel bridge frame brace; The longitudinal channel steel is welded and fixed to form 12 steel bridge frame braces; the horizontal channel steel 4 shown is a 25a channel steel, and the longitudinal channel steel is a 10a channel steel; The distance between the opposite micro piles 1 is 4000mm;

[0021] The construction method of described a kind of pedestrian steel convenient bridge and steel pipe miniature pile connection structure, comprises the following steps:

[0022] 1) At the place where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com