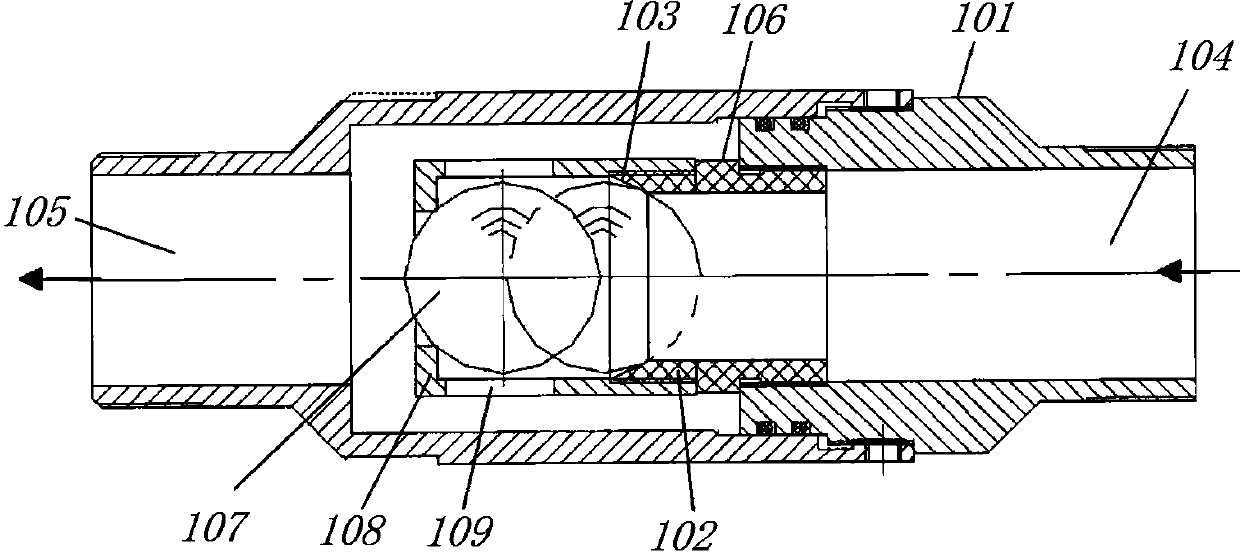

Valve ball type check valve

A single-flow valve and valve ball technology, applied in the field of ball-type check valves, can solve the problem of being difficult to adapt to the working state of non-vertical installation, and achieve the effects of simple structure, good versatility and increased flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

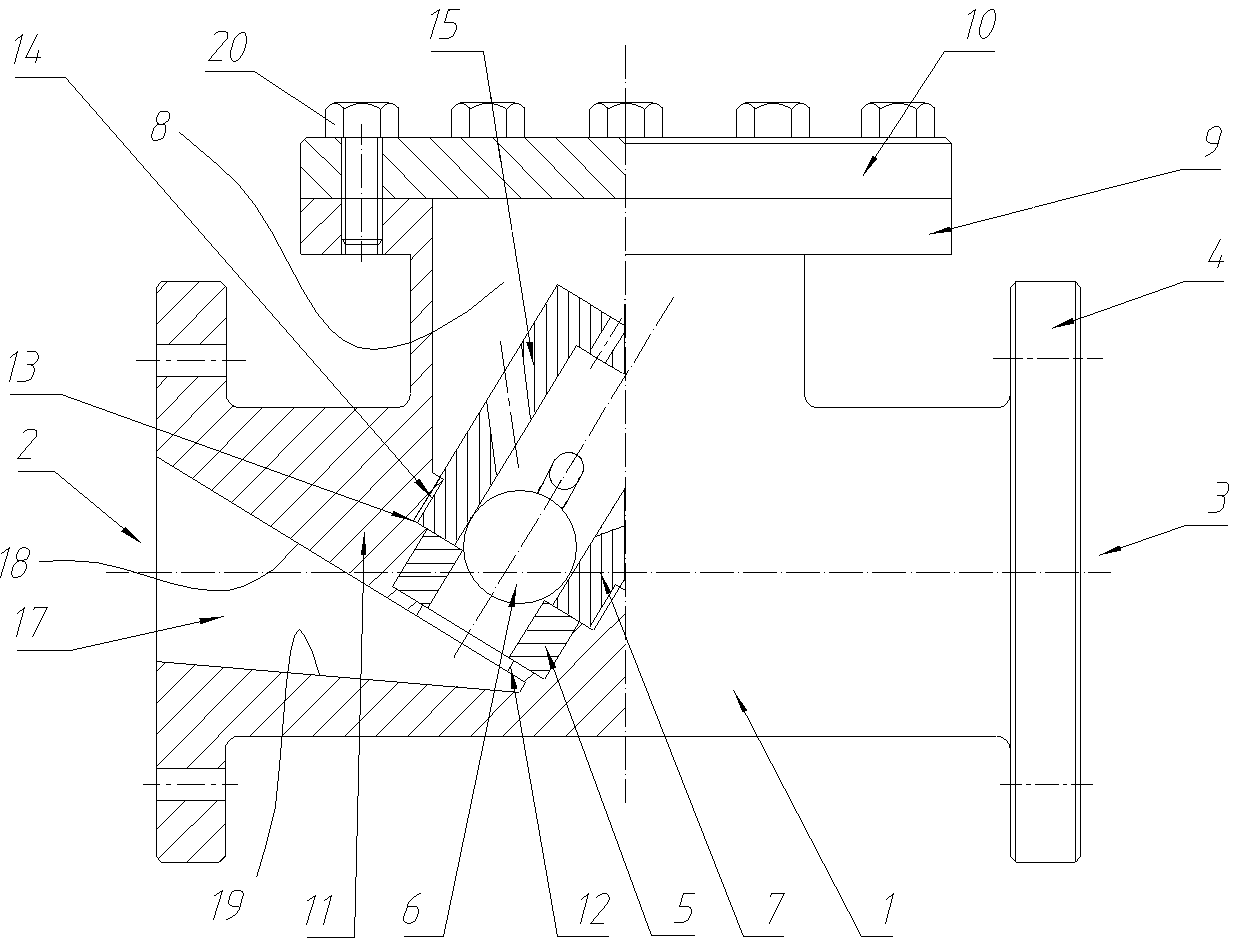

Examples

Embodiment 3

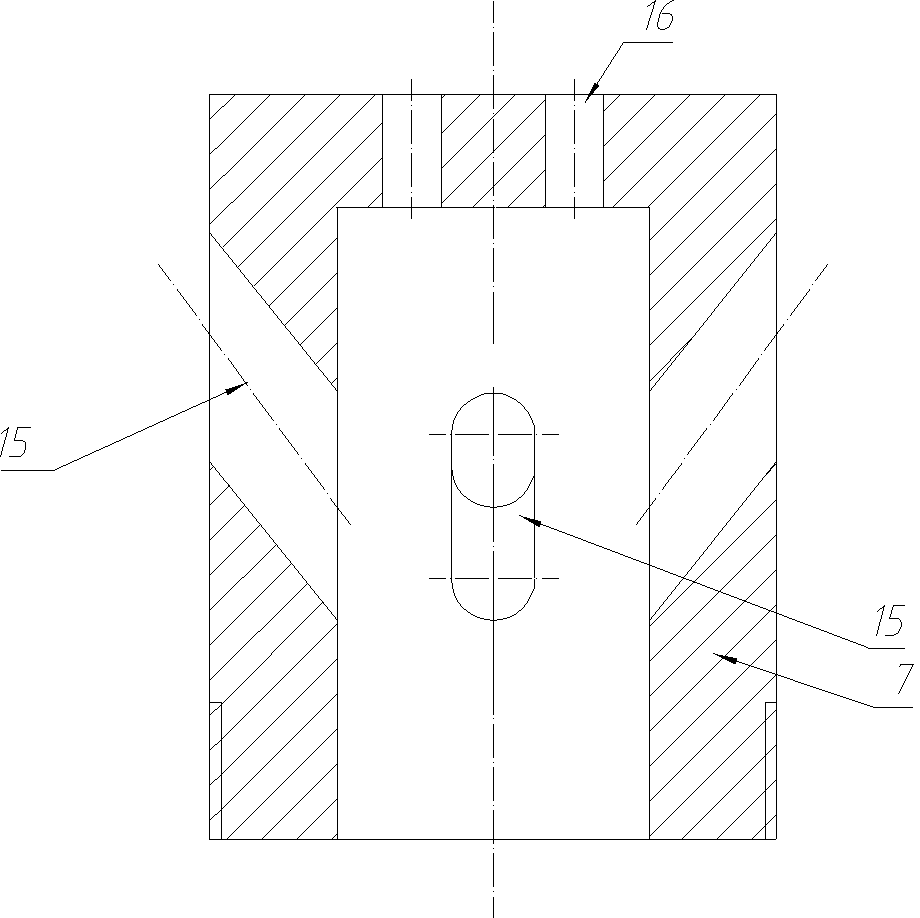

[0038]Embodiment 3 of the present invention. The difference between this embodiment and Embodiment 1 is that the side wall of the ball sleeve 7 in this embodiment is provided with through grooves arranged at intervals in the circumferential direction, and the whole is a cage structure. The groove forms the flow opening.

[0039] In other embodiments of the present invention, the valve body 11 can also be replaced with other shapes, and the inlet 2 and outlet 3 of the check valve can also adopt other distribution forms, for example, the inlet 2 and the outlet 3 are arranged vertically. The axes of the valve seat 5 and the ball sleeve 7 can be arranged obliquely with respect to the direction of the inlet 2 or the direction of the outlet 3 . In addition, in other embodiments, the ball sleeve 7 can also be fixed on the valve body 11 by other means, such as integrally manufactured on the valve body 11 , or fixed on the valve body 11 by welding. In addition, in other embodiments, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com