Hydraulic control sliding sleeve

A sliding sleeve and hydraulic technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of inability to efficiently realize multiple repeated switches, inconvenient exploration wells, cumbersome operations, etc., to achieve guaranteed The effect of smooth operation and sealing reliability, convenient switch operation, and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

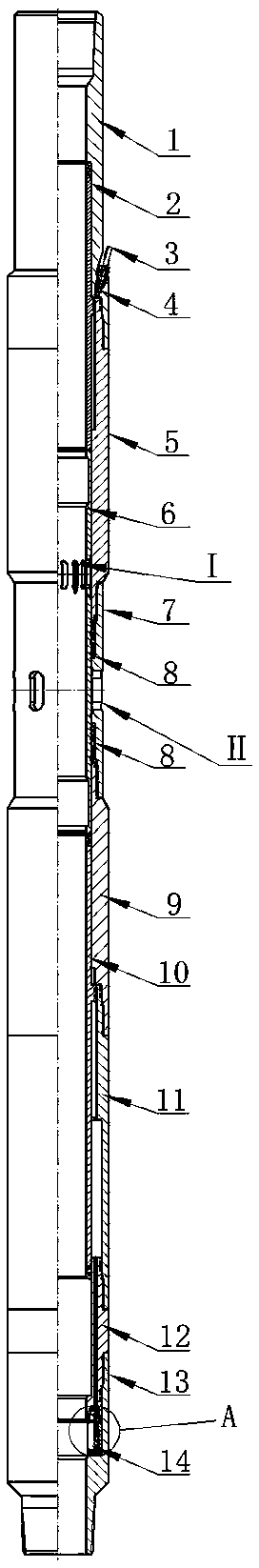

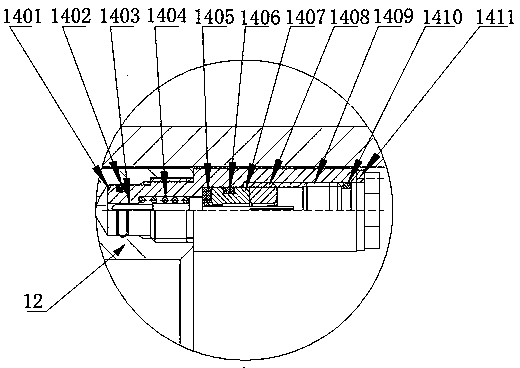

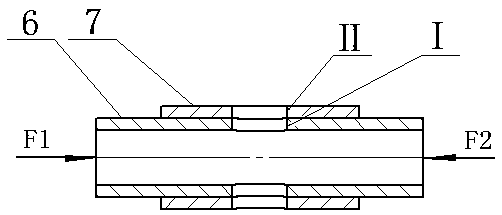

[0020] Such as figure 1 , figure 2 As shown, the hydraulic control sliding sleeve provided by the present invention includes an upper joint 1, a driving cylinder 5, a middle joint 7, a first transition joint 9, a cylinder body 11, a second transition joint 12, and a lower joint 13, which are sequentially Threaded connection and sealing; the driving piston 2 is set in the upper joint 1 and the driving cylinder 5, and the O-ring a is sealed with the upper joint 1 and the driving cylinder 5 to form a hydraulic cylinder, and the control pipeline 3 is fixed on the upper joint 1 with the pipeline joint 4 The upper part communicates with the hydraulic cylinder; the central pipe 6 is set in the driving cylinder 5, the middle joint 7 and the first transition joint 9 to abut against the lower end of the driving piston 2, and is combined with the upper and lower sets of seals 8 located in the middle joint 7 To form a seal, the upper pipe wall of the central pipe 6 is provided with mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com