Novel oil filter by-pass valve mounting structure

A technology of installation structure and bypass valve, which is applied in the installation/connection of lubricant purification devices, mechanical equipment, engine components, etc., can solve the problems of high difficulty in processing and production, high replacement cost, etc., and achieves good processing convenience and convenience. Disassembly and maintenance, good oil sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

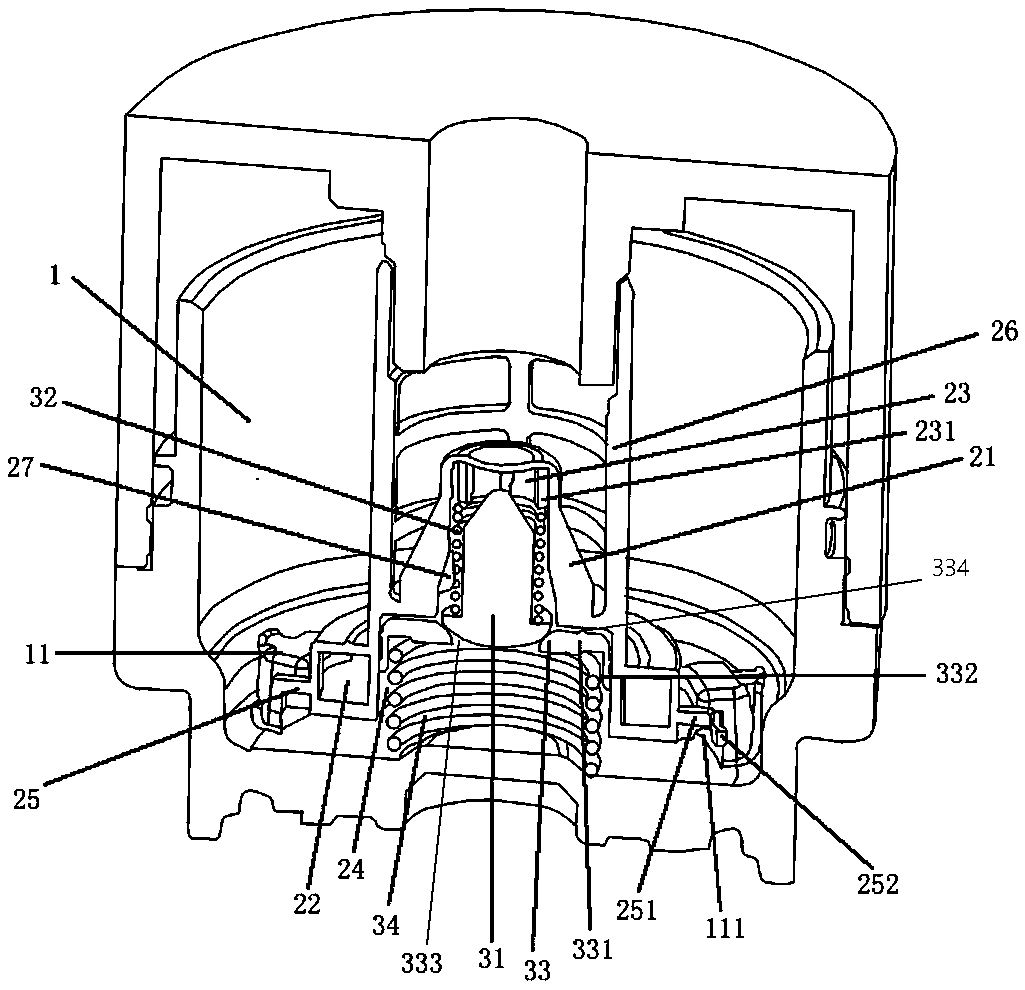

[0030] Such as figure 1 The installation structure of a new machine filter bypass valve shown includes an oil filter screw cover 1 and a bypass valve arranged inside the screw cover 1, and the screw cover 1 includes at least two connecting parts arranged circumferentially around its axis 11. The bypass valve includes a housing and a bypass assembly, wherein the housing is a plastic housing integrally formed. The housing includes a valve housing 21 and a functional housing 22 located below the valve housing 21. The functional housing 22 has a large cross-sectional area The annular shell, thus can have good mechanical properties, the valve shell 21 has the first valve chamber 23 with the opening downward, and the first valve chamber 23 is provided with two opposite support ridges 231 circumferentially spaced on its wall surface , the bypass assembly is located inside the valve housing 21; the valve housing 21 is combined with the inner wall of the functional housing 22 to form a...

Embodiment 2

[0035] The technical solution described in this embodiment is similar to that of Embodiment 1, the difference is that there are multiple connecting parts 11 , and the openings of the opening slots 111 have the same rotation direction. When the bypass valve is installed in this embodiment, the installation part 25 is snapped into the connection part 11 in order to put it vertically and then turn it, which is suitable for the situation where the installation space is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com