Working device of engine waste gas power turbine driving water pump

A technology for power turbines and working devices, which is applied in the direction of engine cooling, pump devices, engine components, etc., can solve problems such as engine power loss, achieve the effect of avoiding leakage problems, and the control structure is simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

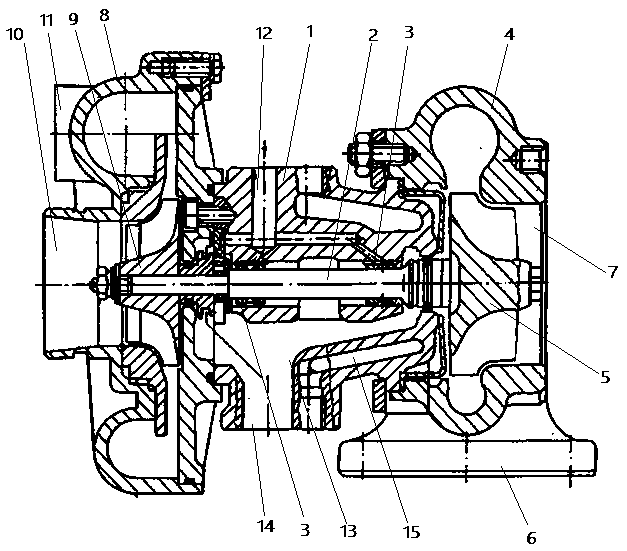

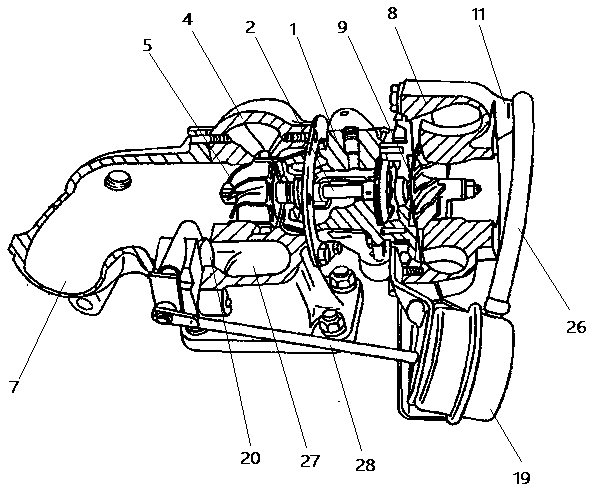

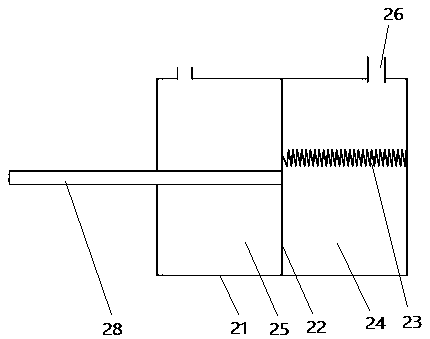

[0016] Please combine figure 1 ,to image 3 As shown, the working device of the engine exhaust gas power turbine driving the water pump includes a radial power turbine 1a, a centrifugal water pump 1b and an installation body 1. The installation body 1 is fixed between the radial power turbine 1a and the centrifugal water pump 1b, and the common shaft 2 passes through two floating The bearing 3 is supported in the mounting body 1 . The radial power turbine 1a includes a volute 4, a turbine impeller 5, a circumferential air inlet 6 and an axial exhaust port 7, and the volute 4 is provided with a circumferential air inlet 6 and an axial exhaust port 7 to guide exhaust gas evenly into the radial power The turbine 1a is also introduced into the exhaust manifold, which is cast with heat-resistant alloy cast iron and has a smooth inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com