An oblique pin locking hose joint

A hose joint and oblique pin technology, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems of poor protection effect, large compression of the rubber ring, scratches of the rubber ring cloak, etc. The effect of sealing and fixing, improving assembly efficiency, and quick and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

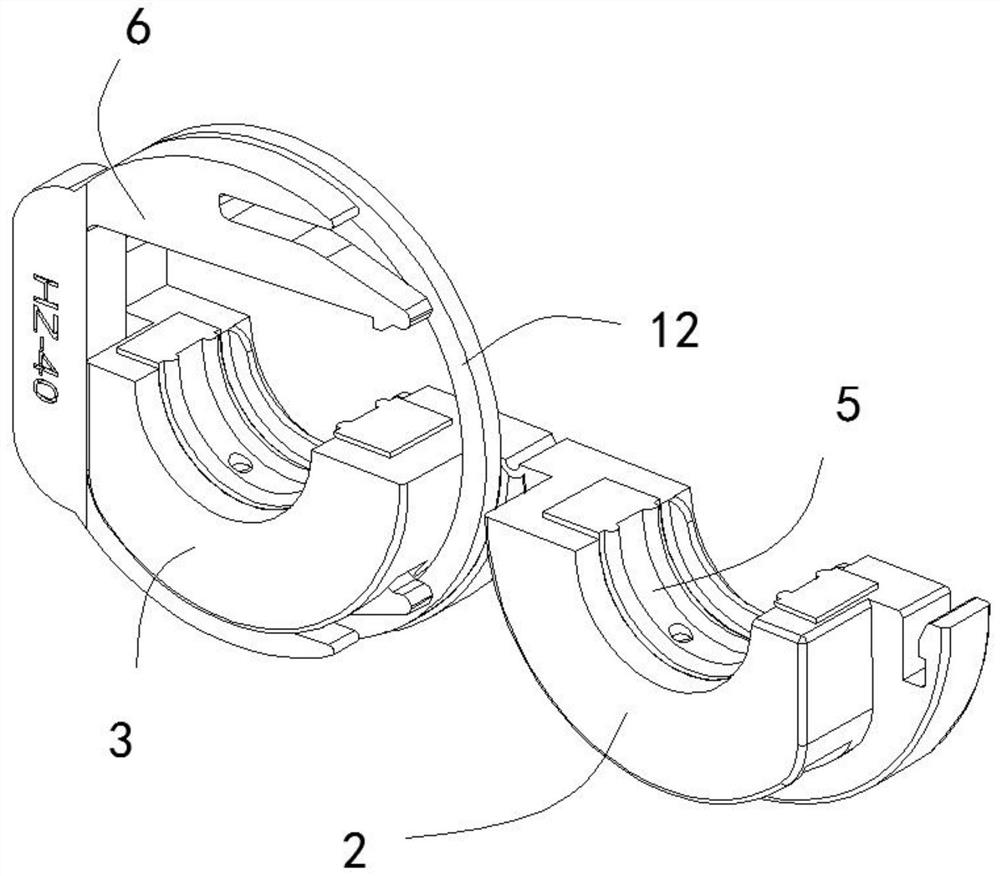

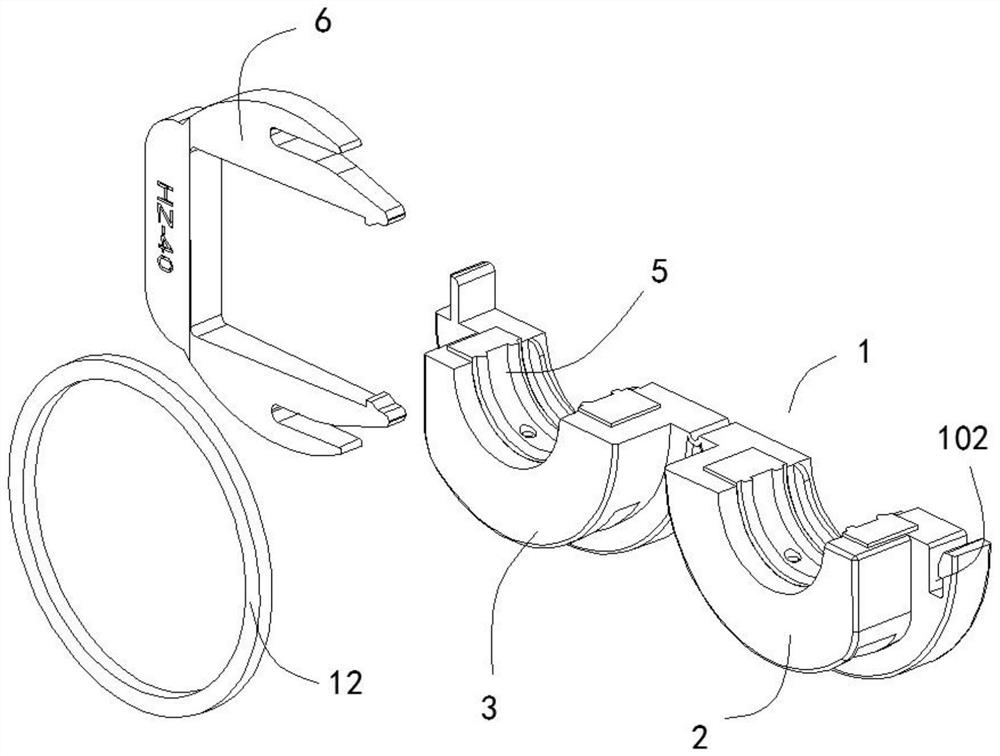

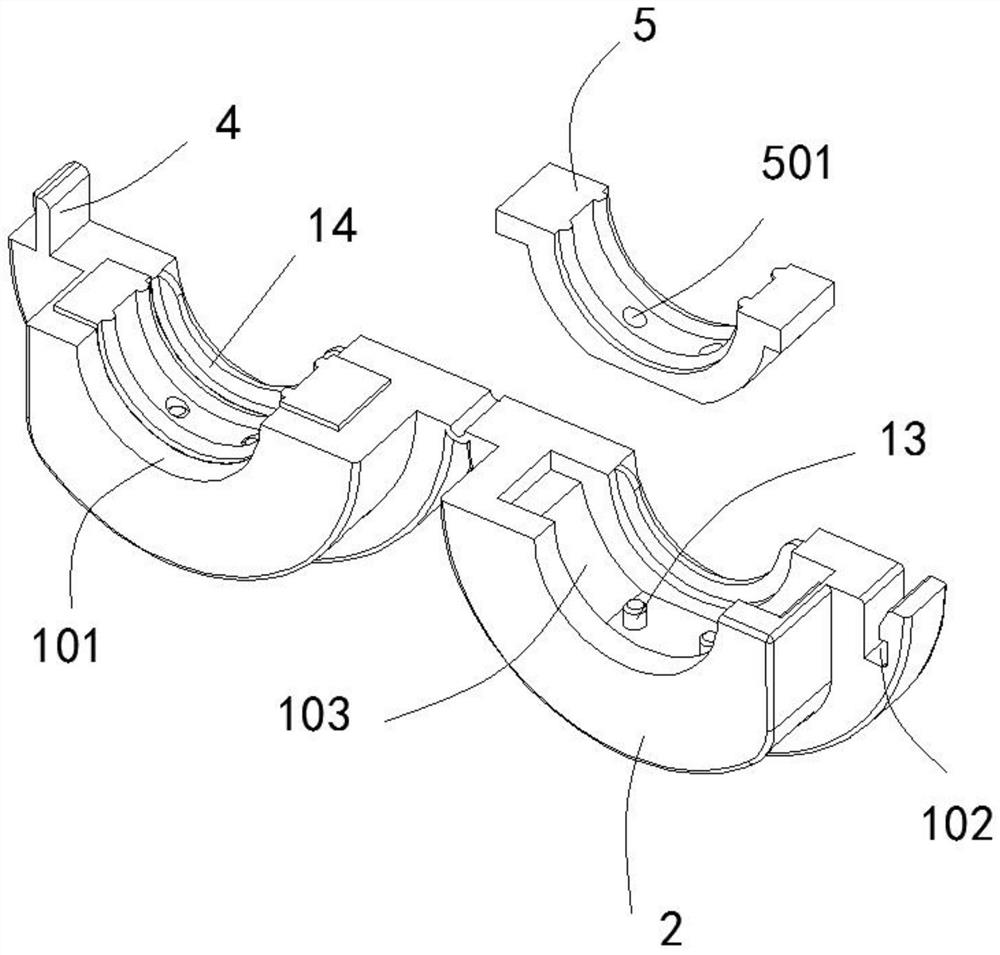

[0033]The oblique pin of this embodiment locks the hose connector, refer toFigure 1-4 :Including the shell 1, the shell 1 is in the shape of a stepped shaft, and the middle part is provided with a through hole 101. The arc outer wall of the cylinder with a smaller diameter is cut with a plane, and the shell 1 is vertical along the plane. The straight symmetrical cut is divided into the upper half 2 and the lower half 3, the upper half 2 and the lower half 3 are softly connected together at one end, and the lower half 3 at the other end is fixed on the cross-section of the top with a clamping tooth The plug-in board, the upper half 2 is provided with a slot 102 matching the plug-in board on the cross section, and the upper half 2 and the lower half 3 are respectively provided with a semi-circular slot 103 coaxial with the through hole 101 inward. A semi-annular silicone inner core 5 is fixed and clamped in the groove 103. The middle part of the arc-shaped outer wall of the cylinder w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com