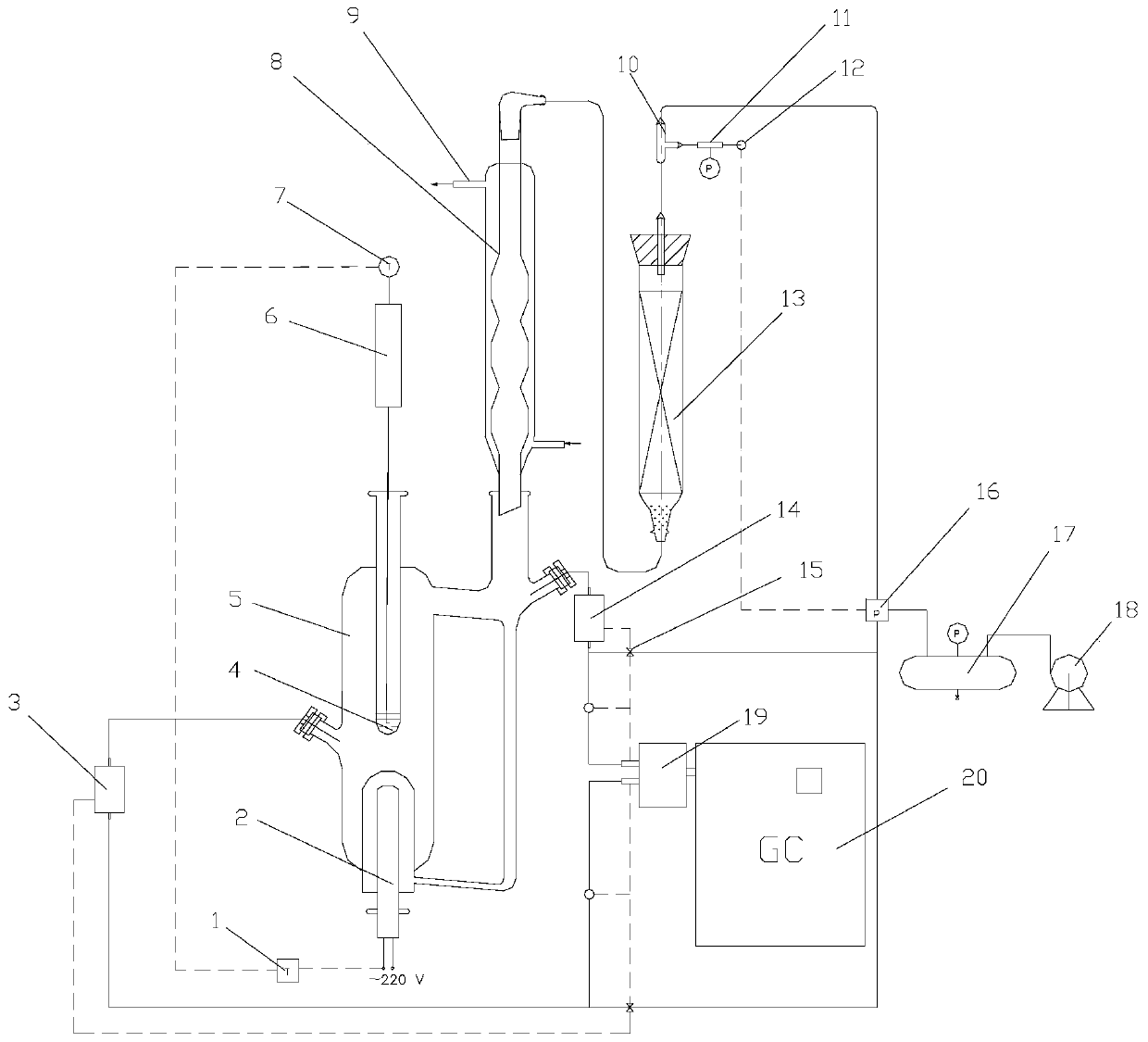

A decompression gas-liquid balance device with the function of automatic pressure control and sample measurement

A gas-liquid balancing and balancing device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as difficulty in sampling, and achieve the effect of convenient and aggressive sample collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

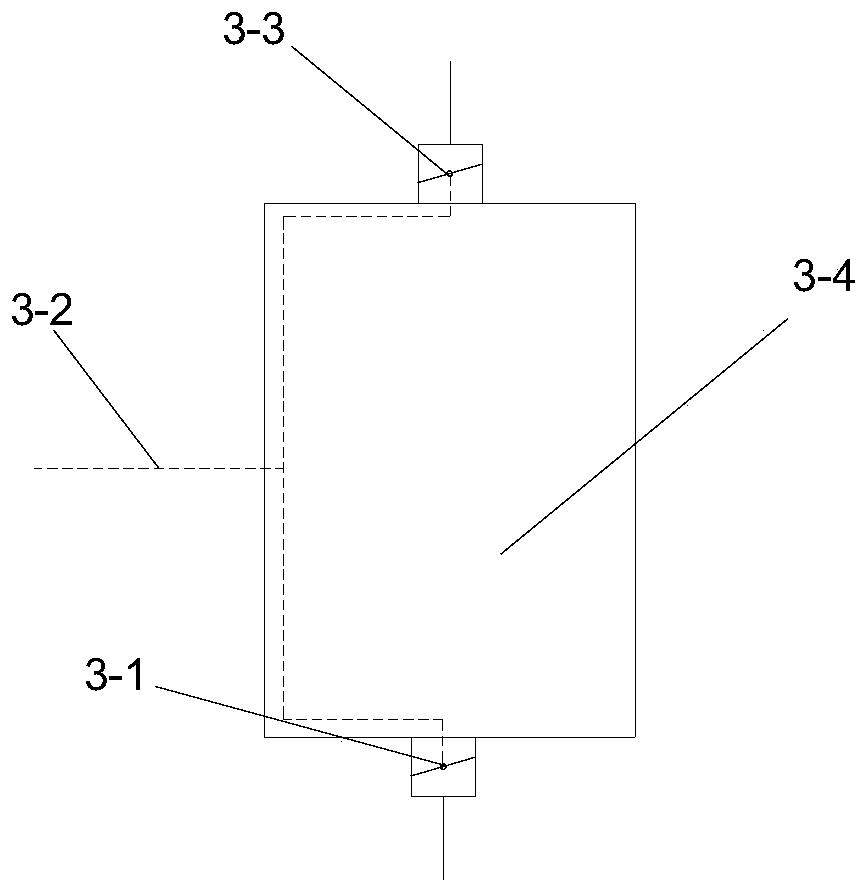

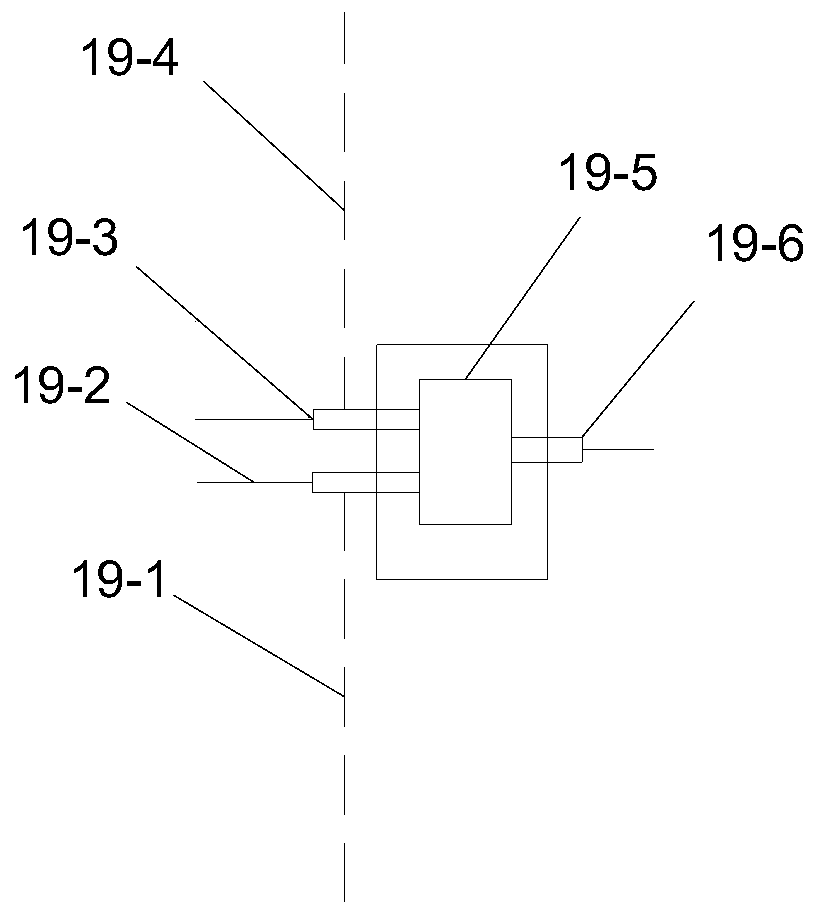

Embodiment 1

[0044] (1) Detect the airtightness of the gas-liquid balance measuring device; (2) Add the solution H to be tested into the gas-liquid balance kettle 5 2 O+CH 3 OH+KCl system 50mL, set the system pressure to be detected through the gas pressure controller 16, close the inlet and sampling valves of the gas phase sampler 3 and the liquid phase sampler 14, open the vacuum pump 18 and the temperature controller 1; (3) Wait for the system After reaching the equilibrium state, turn on the power supply of the sampling controller 19, and the controller completes the sampling operation by controlling the sampling valves of the gas phase sampler 3 and the liquid phase sampler 14; (4) after the sampling operation is completed, the sampling controller 19 Control to open the micro-diaphragm vacuum pump 19-5, respectively complete the sampling operation for the gas phase sample in the gas phase sampler 3 and the liquid phase sample in the liquid phase sampler 14, and inject the sample into ...

Embodiment 2

[0048] (1) Detect the airtightness of the gas-liquid balance measuring device; (2) Add the solution H to be tested into the gas-liquid balance kettle 5 2 O+CH 3 OH+NaCl system 50mL, set the system pressure to be detected through the gas pressure controller 16, close the inlet and sampling valves of the gas phase sampler 3 and the liquid phase sampler 14, open the vacuum pump 18 and the temperature controller 1; (3) Wait for the system After reaching the equilibrium state, turn on the power supply of the sampling controller 19, and the controller completes the sampling operation by controlling the sampling valves of the gas phase sampler 3 and the liquid phase sampler 14; (4) after the sampling operation is completed, the sampling controller 19 Control to open the micro-diaphragm vacuum pump 19-5, respectively complete the sampling operation for the gas phase sample in the gas phase sampler 3 and the liquid phase sample in the liquid phase sampler 14, and inject the sample into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com