Method and device for realizing on-line analysis on simulated combustion of cigarettes by using thermogravimetric analyzer and GC/MS

A thermogravimetric analyzer and analysis method technology, applied in measurement devices, analysis materials, instruments, etc., can solve the problems of inaccurate qualitative and quantitative, low content of cracking products, and small sample consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

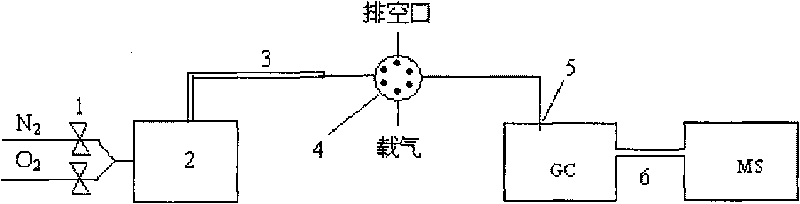

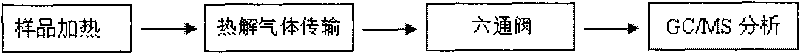

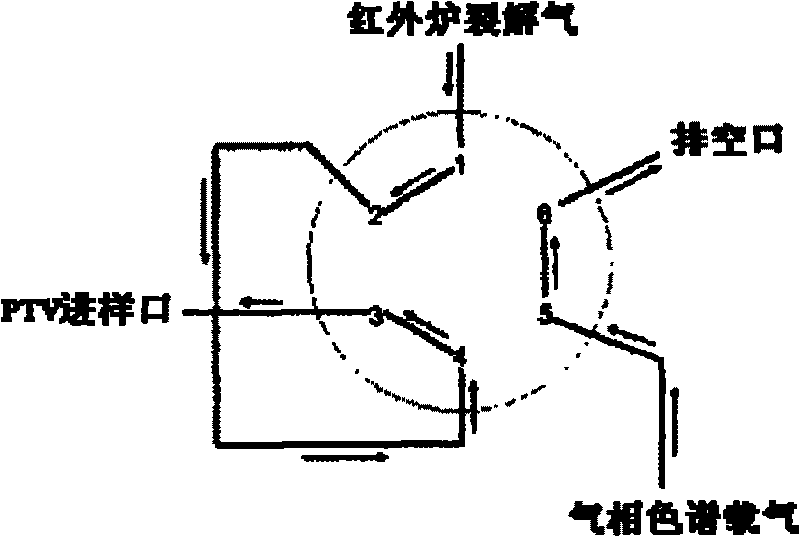

Method used

Image

Examples

Embodiment 1

[0033] Weigh 20 mg of cigarette powder powder sample that has been crushed through a 40-mesh sieve, put it into the crucible of the thermogravimetric analyzer, set the temperature rise rate of the sample on the thermogravimetric analyzer to be 10 / °C min, adjust the carrier gas flow rate (nitrogen 30mL / min , oxygen 10mL / min), connect the temperature-controllable transfer line (transfer line temperature 280°C), and start to heat up; the six-way valve starts to work, and the thermal weight loss product continuously passes through the temperature-controllable transfer line and the six-way valve into the PTV inlet. A sample was taken every 20 minutes, and the sample captured at the PTV inlet was analyzed according to the GC / MS analysis conditions.

[0034] See GC-MS spectrum ( Figure 5 , Image 6 ):

[0035] As can be seen from the figure above, using the device thermogravimetric analyzer and GC-MS of the invention can carry out simulated combustion experiments on cigarettes, an...

Embodiment 2

[0037] Weigh 50 mg of tobacco dust sample crushed through a 40-mesh sieve from cigarette shreds, put it into the crucible of the thermogravimetric analyzer, set the sample temperature rise program on the thermogravimetric analyzer to 40°C / min, adjust the carrier gas flow rate (nitrogen 35mL / min, Oxygen 5mL / min), connect the temperature-controllable transfer line (transfer line temperature 280 ℃), start to heat up; the six-way valve starts to work, and the thermal weight loss product continuously passes through the temperature-controllable transfer line and the six-way valve into the PTV inlet, every 20min A sample is taken, and the sample captured at the PTV inlet is analyzed according to the GC / MS analysis conditions.

[0038] See GC-MS spectrum ( Figure 7 , Figure 8 ):

[0039] As can be seen from the figure above, using the device thermogravimetric analyzer and GC-MS of the invention, it is possible to conduct simulated combustion experiments on cigarettes under differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com