High-performance power supply heat sink

A radiator, high-performance technology, used in electrical components, structural parts of electrical equipment, cooling/ventilation/heating renovation, etc., can solve the problems of low heat dissipation effect, low tooth density, low stability, etc., and achieve extremely high heat dissipation effect. The best, guarantee the stability, the use effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

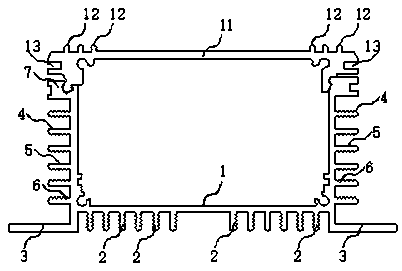

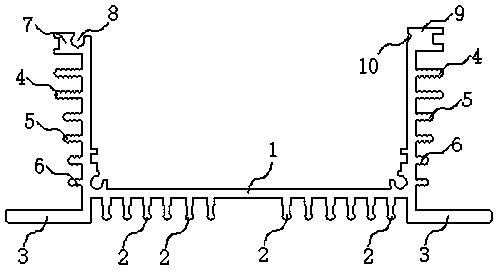

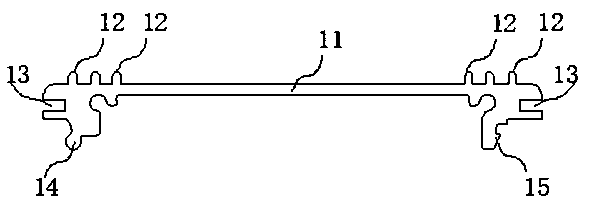

[0019] As shown in the figure, a high-performance power radiator is characterized in that it includes a bottom case and a top plate, the bottom case is an integral structure, the bottom case is a U-shaped structure, and the bottom of the bottom case is provided with a first heat dissipation The number of the first heat dissipation strips is 12, which are divided into two groups and arranged on both sides of the bottom of the bottom case, and the number of each group is 6; the first heat dissipation strips have a long strip structure, and the first One end of the bar is a rectangular prism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com