Workpiece frame for cleaning circular saw web and method of clamping circular saw blade in workpiece frame for cleaning circular saw blade

A circular saw blade and workpiece frame technology, applied in the field of cleaning of circular saw blades, can solve the problems of easy loosening or even collision of circular saw blades, poor cleaning effect, etc., to achieve environmental protection, convenient clamping process, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with example and accompanying drawing, the present invention is described in further detail.

[0018] Referring to the attached picture:

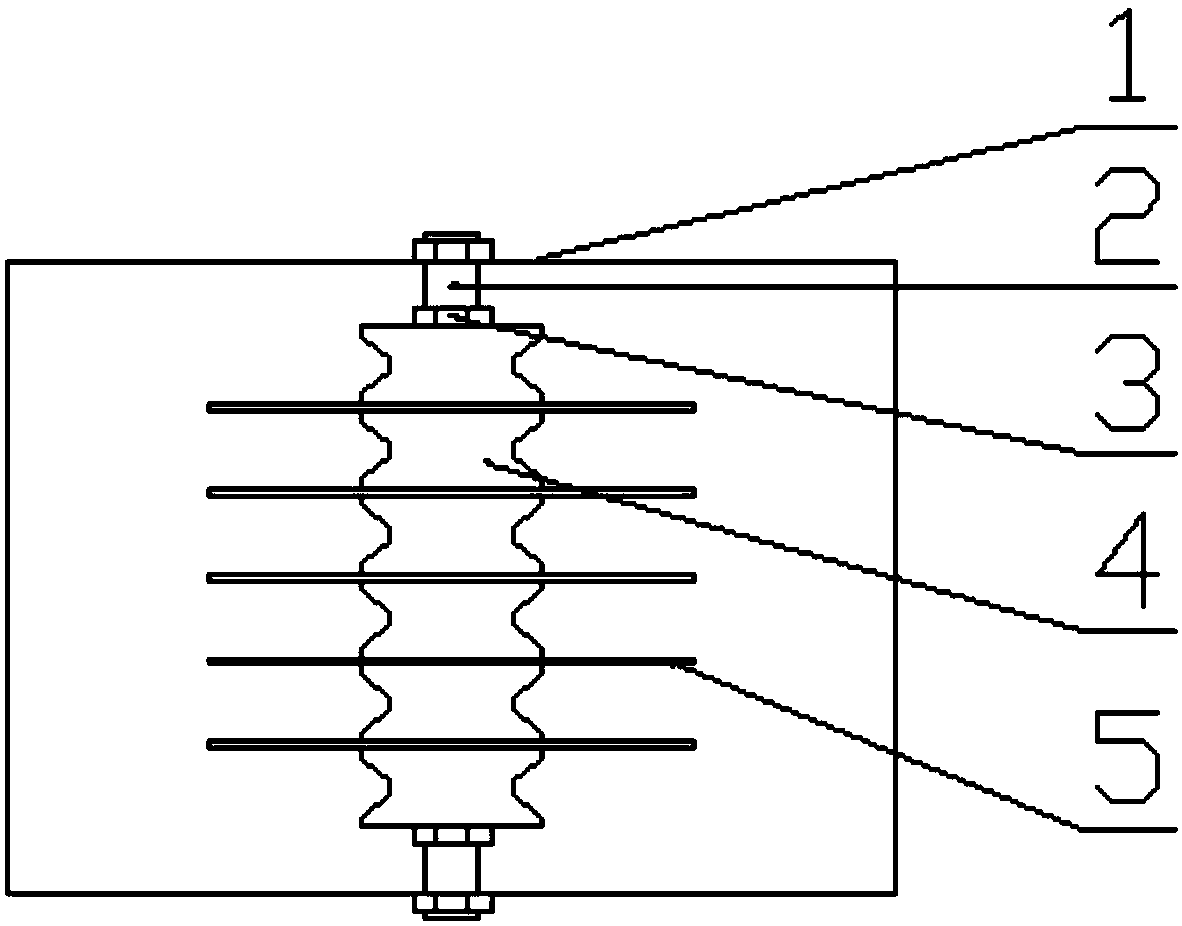

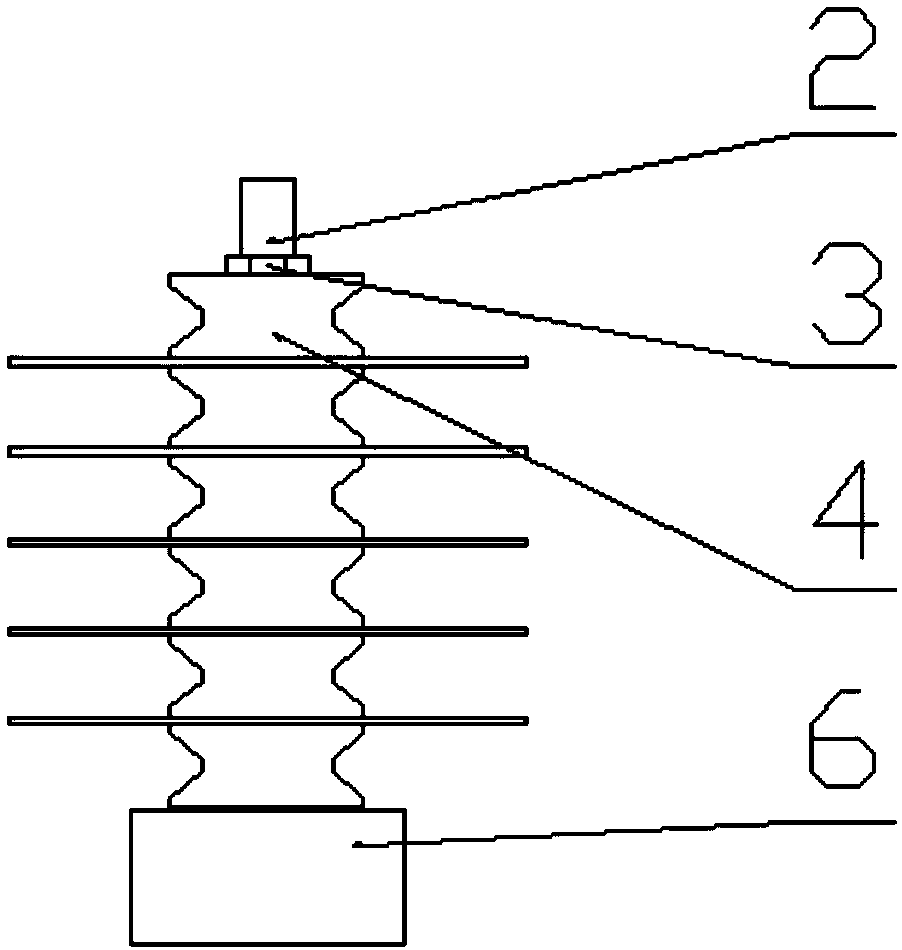

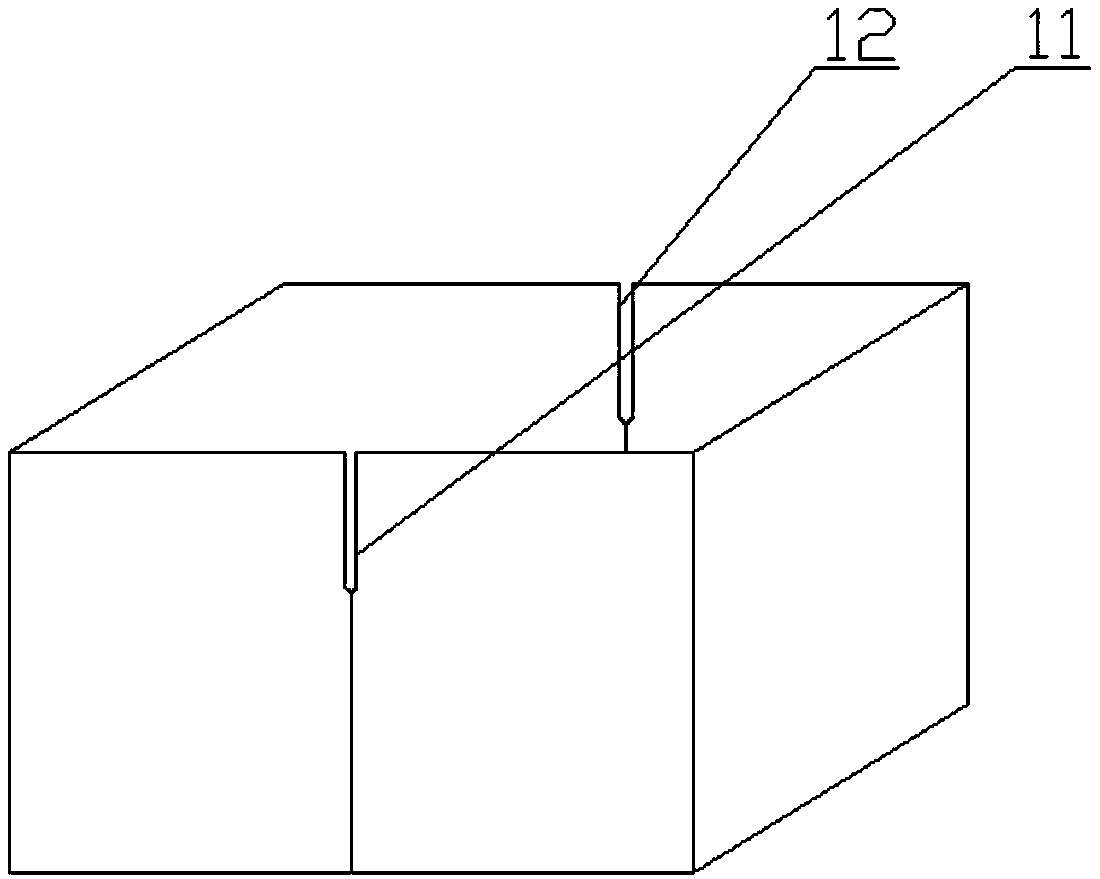

[0019] 1—main frame; 2—support rod; 3—nut; 4—spacer; 5—circular saw blade; 6—special pad; 11—the first U-shaped opening of the main frame; 12—the second U-shaped opening of the main frame ; 41—cylindrical surface of spacer; 61—counterbore hole of special pad; 62—through hole of special pad.

[0020] The workpiece frame for circular saw blade cleaning of the present invention is characterized in that: the first U-shaped opening 11 of the main frame and the second U-shaped opening 11 of the main frame are respectively opened on two opposite sides of the main frame 1 for accommodating the circular saw blade 5 U-shaped opening 12, the support rod 2 is erected on the first U-shaped opening 11 of the main frame and the second U-shaped opening 12 of the main frame, and the circular saw blade 5 and the spacer 4 are spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com