Outer ring anti-napping side roller support bearing and eighteen-high mill thereof

A technology for supporting bearings and rough side rolls, which is applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., and can solve problems such as large running resistance and easy pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

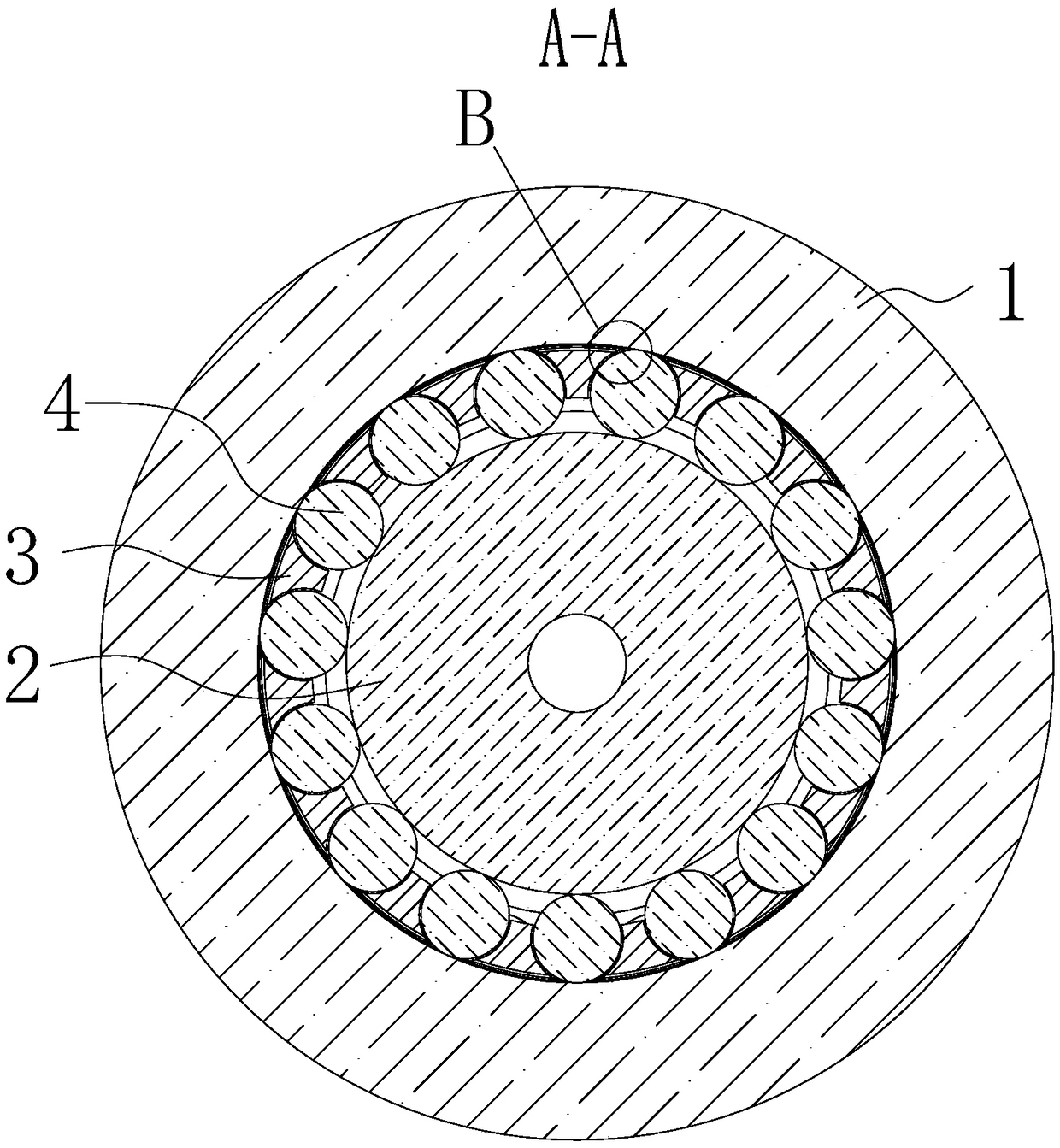

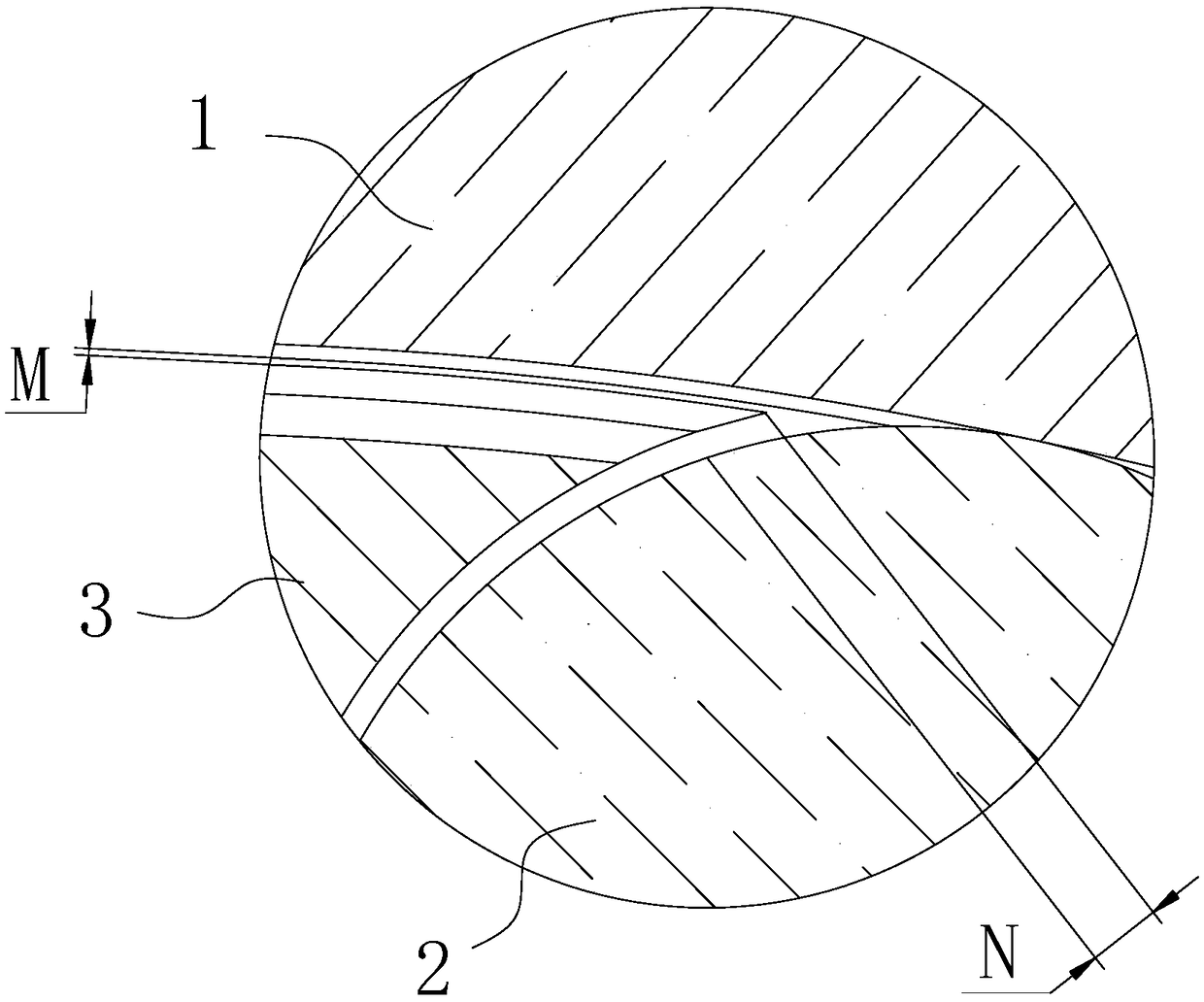

[0031] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0032] Such as Figure 1 to Figure 6 As shown, an outer ring anti-snapping side roller support bearing includes an inner ring shaft 2, a supporting outer ring 1 and a cage 3, and the cage 3 is arranged between the inner wall surface of the supporting outer ring 1 and the outer wall surface of the inner ring shaft 2. The outer ring surface of the cage 3 expands radially outward as a whole, so that a first radial gap M is formed between the outer ring surface of the cage 3 and the inner wall surface of the supporting outer ring 1;

[0033] A number of pockets are provided on the cage 3, and rollers 4 are respectively installed in each pocket, and the pockets form a slit on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com