Rivet press-fitting device of paper winder

A press-fitting device and paper reel technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems of product surface friction, cumbersome operation steps, and needs to be improved to achieve guaranteed Press-fit effect, effect of expanding detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

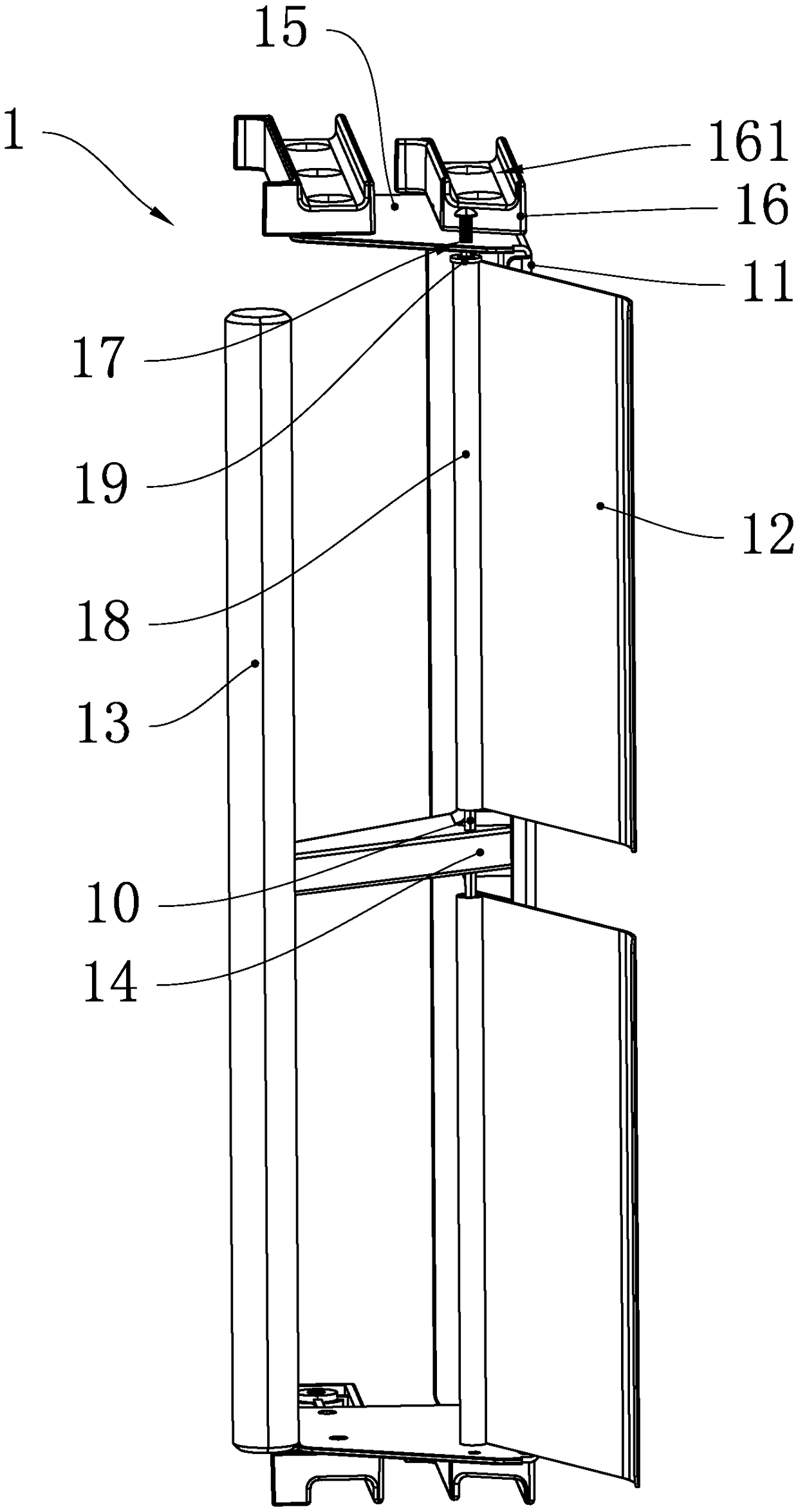

[0028] see figure 1 , the paper reel 1 of the present invention comprises a panel 11, two cover plates 12 and a placement rod 13, the two ends of the panel 11 are respectively connected with side plates 15, and the two side plates 15 are respectively provided with screw holes 17, and the two covers Hollow shafts 18 are respectively arranged on the plates 12, and connecting lines 10 run through the hollow shafts 18 of the two cover plates 12 at the same time, and the connecting lines 10 complete the connection of the two cover plates 12, and a connecting line Block 14, the connecting wire 10 also passes through the connecting block 14, and the connecting block 14 is connected to the placement rod 13. The rivet pressing device of the present invention presses the rivet into the screw hole 17 of the side plate 15 and the hollow shaft 18 at the same time, so as to complete the connection between the panel 11 and the cover plate 12 . The side plate 15 is also provided with a lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com