Online labeling production line of non-setting adhesive labels

A production line and labeling technology, applied in the direction of coating, etc., can solve the problems of label warping, inability to realize real-time online labeling of products, and large volume, so as to accelerate crystal deformation, improve glue bonding and flow performance, and avoid labeling Warping and bubbling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail;

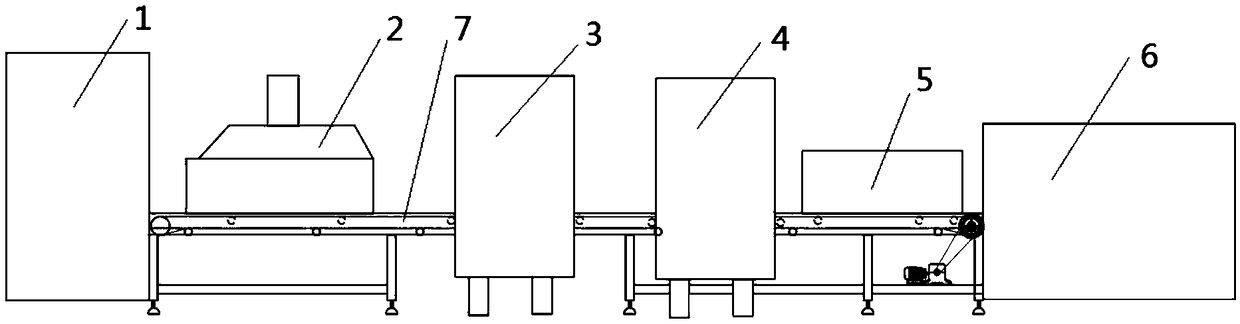

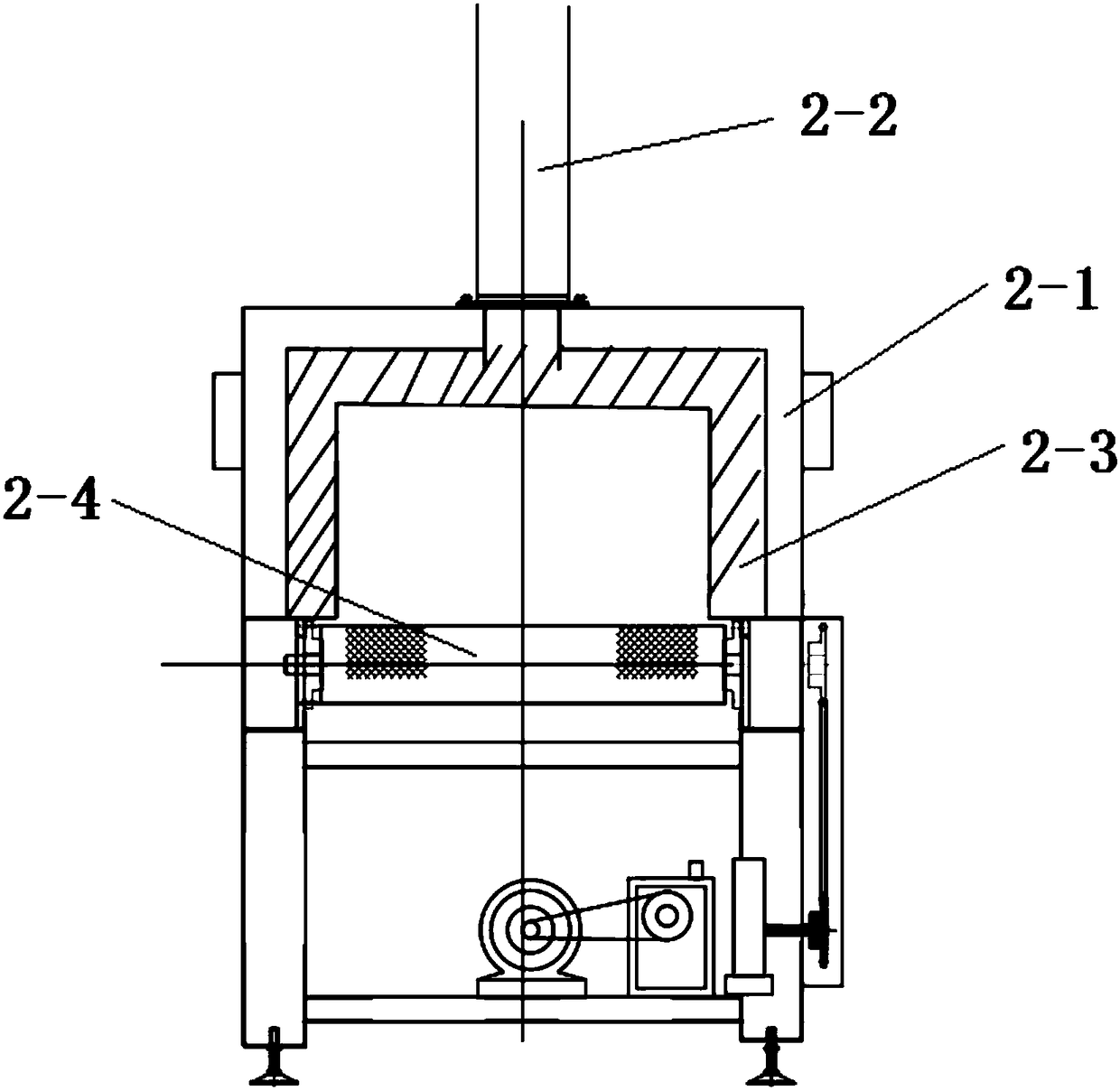

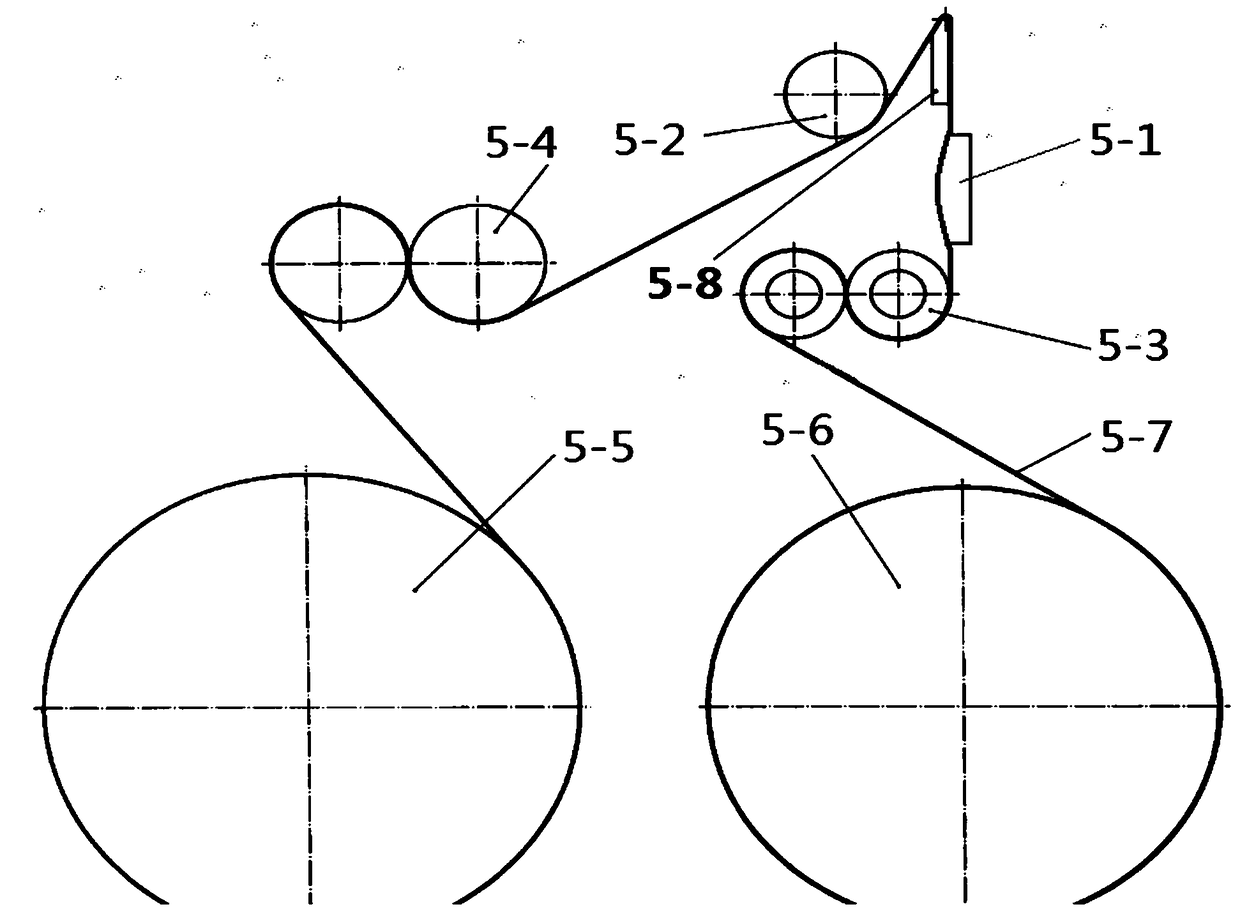

[0012] An online self-adhesive label labeling production line is characterized in that it includes a conveyor belt that passes through a cooling device, a weighing device, a leak detection device, a self-adhesive label labeling machine and a palletizing system in sequence from a blow molding machine ; The cooling device includes a box body 2-1, a connecting pipe 2-2, the top of the box body is connected with an external cooler through a connecting pipe, and the inner sides of the box body are provided with side air ducts 2-3, and the inner walls of the side air ducts There are ventilation holes on the top, and the conveyor belt 2-4 is located between the two side air ducts. A preheating plate is set between the label peeling plate and the tension roller of the self-adhesive label labeling machine. The conveyor belt is a stainless steel mesh belt. And thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com