Method for preparing a superabsorbent polymer

A superabsorbent, polymer technology, applied in the direction of absorbent pads, medical science, bandages, etc., can solve problems such as deterioration of absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

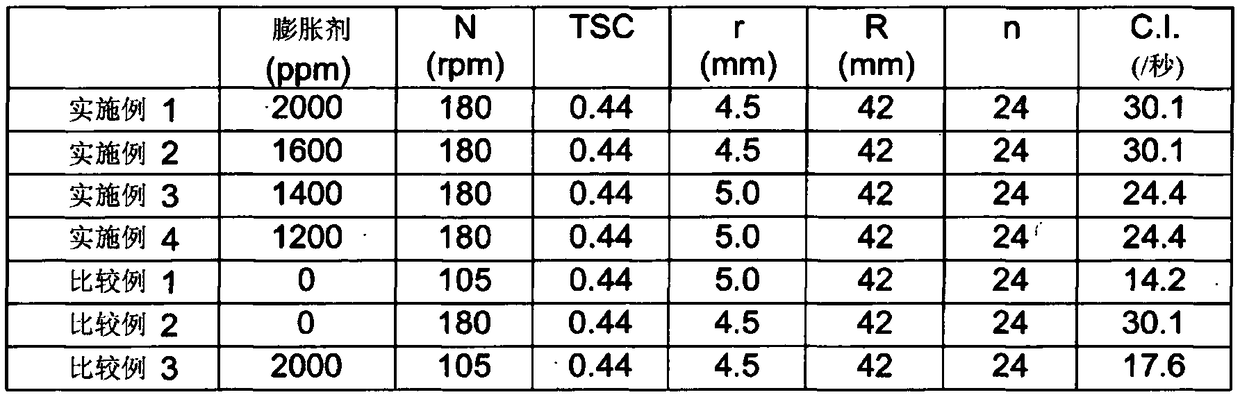

experiment example

[0157] The properties of each superabsorbent polymer prepared in Examples and Comparative Examples were measured and evaluated as follows.

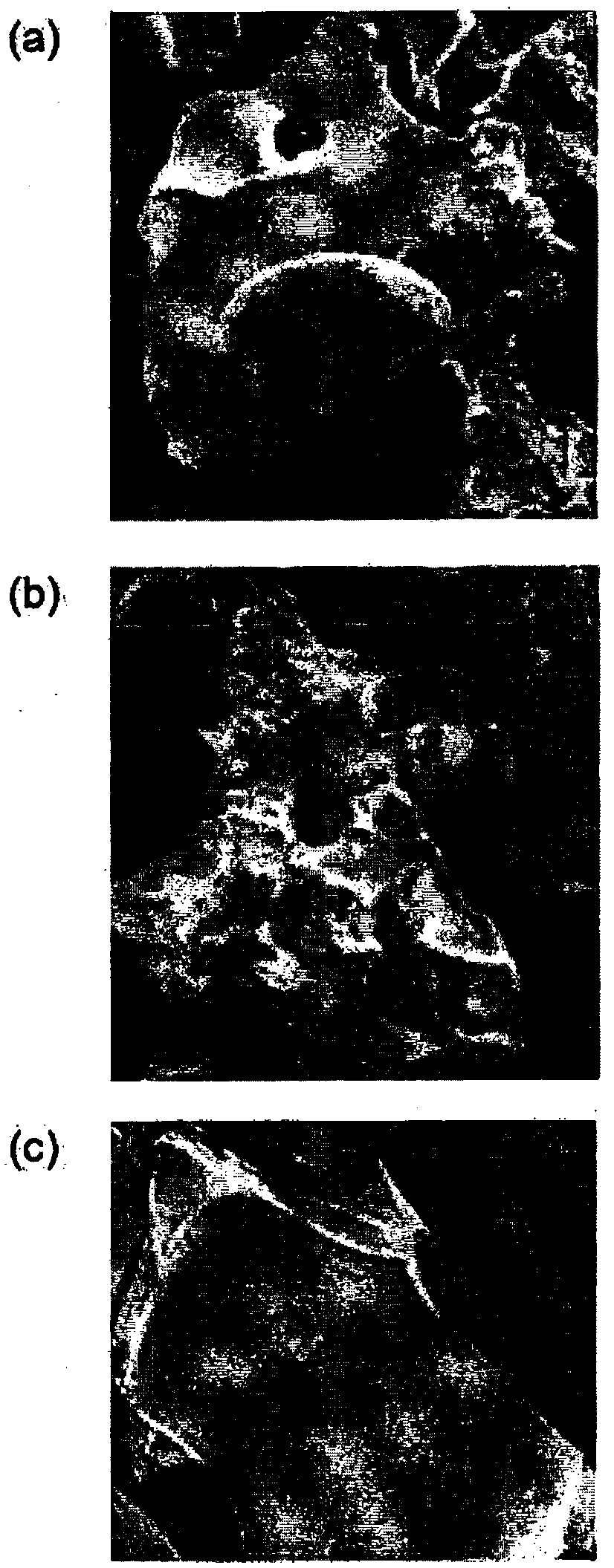

[0158] (1) According to the ratio of particle shape

[0159] Superabsorbent polymer particles were observed with a scanning electron microscope (SEM) to count swollen particles (in which depressions due to swelling occupy 1 / 3 or more of the particle surface) in the total particles (classified if the ratio is less than 1 / 3 are porous particles), porous particles (which contain three or more pores or depressions on the surface with a depth of 10 μm or greater), and unsheared particles (which have a smooth surface due to no particle deformation during the shredding process). surface) ratio.

[0160] Wherein, the expanded particles in the superabsorbent polymer particles according to Example 1 [ figure 1 (a)], porous particles [ figure 1 (b)] and unsheared particles [ figure 1 (c)] SEM images are shown in figure 1 middle.

[0161] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com