Electric-heating comb

A technology of electric heating combs and combs, which is applied in the field of electric heating combs, can solve the problems of difficult use of comb components, modular assembly and poor structural design, etc., and achieve the effects of compact structure, low production cost and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

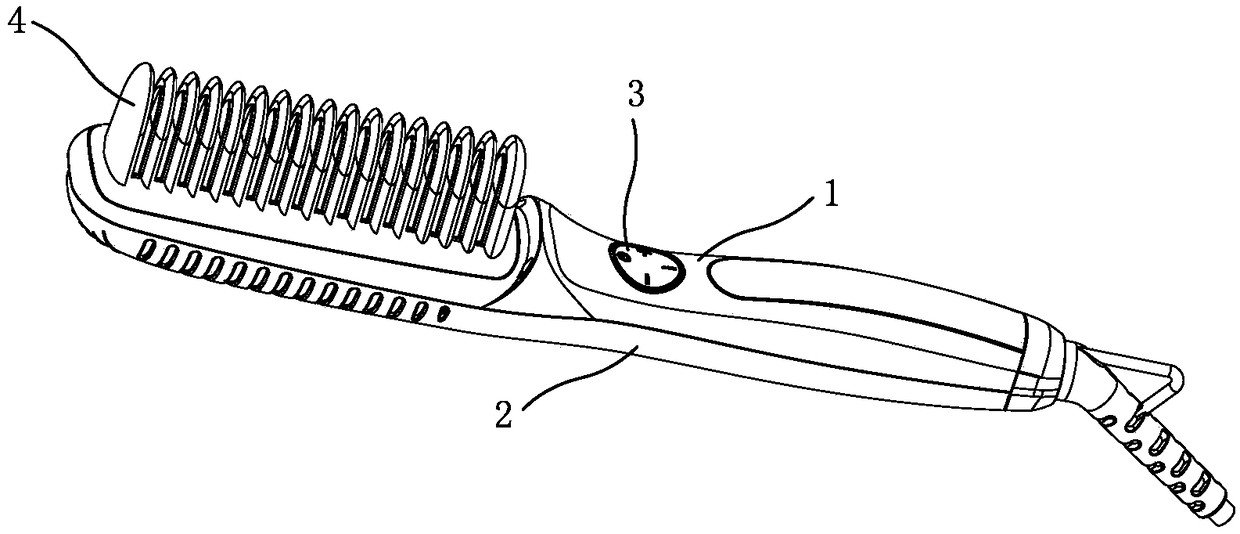

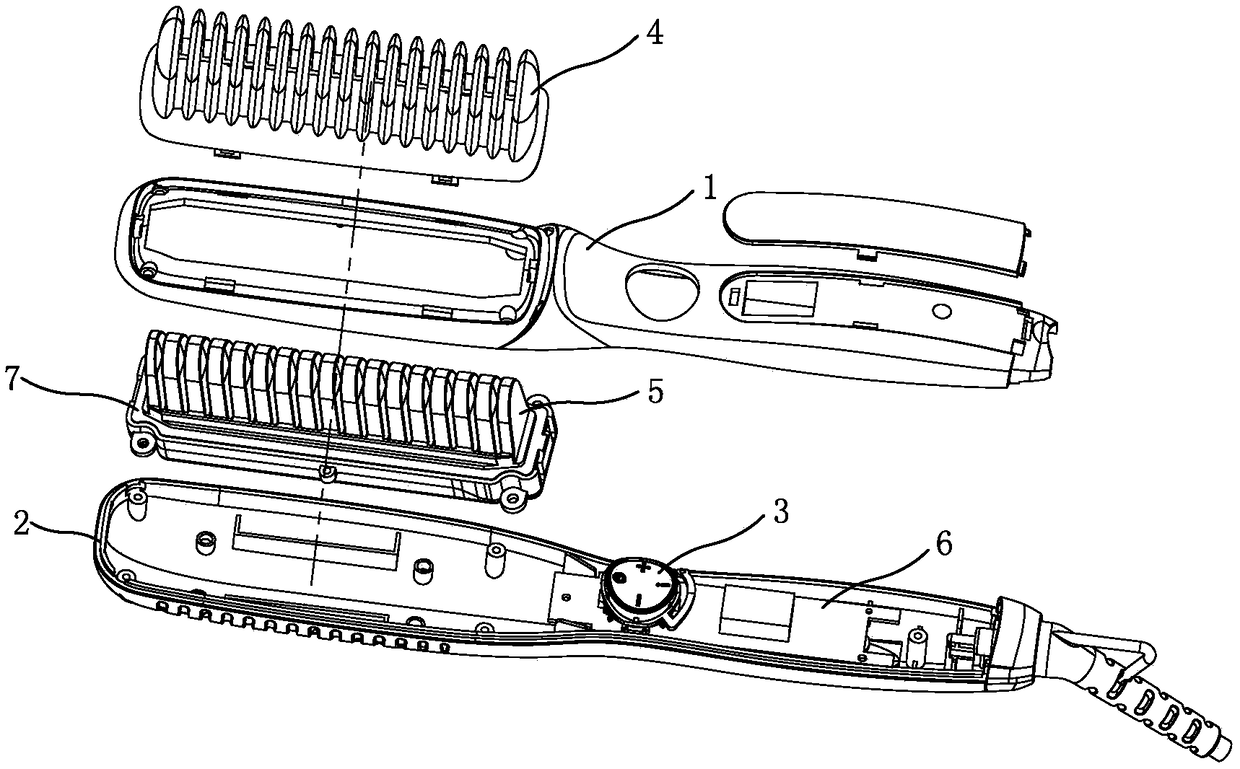

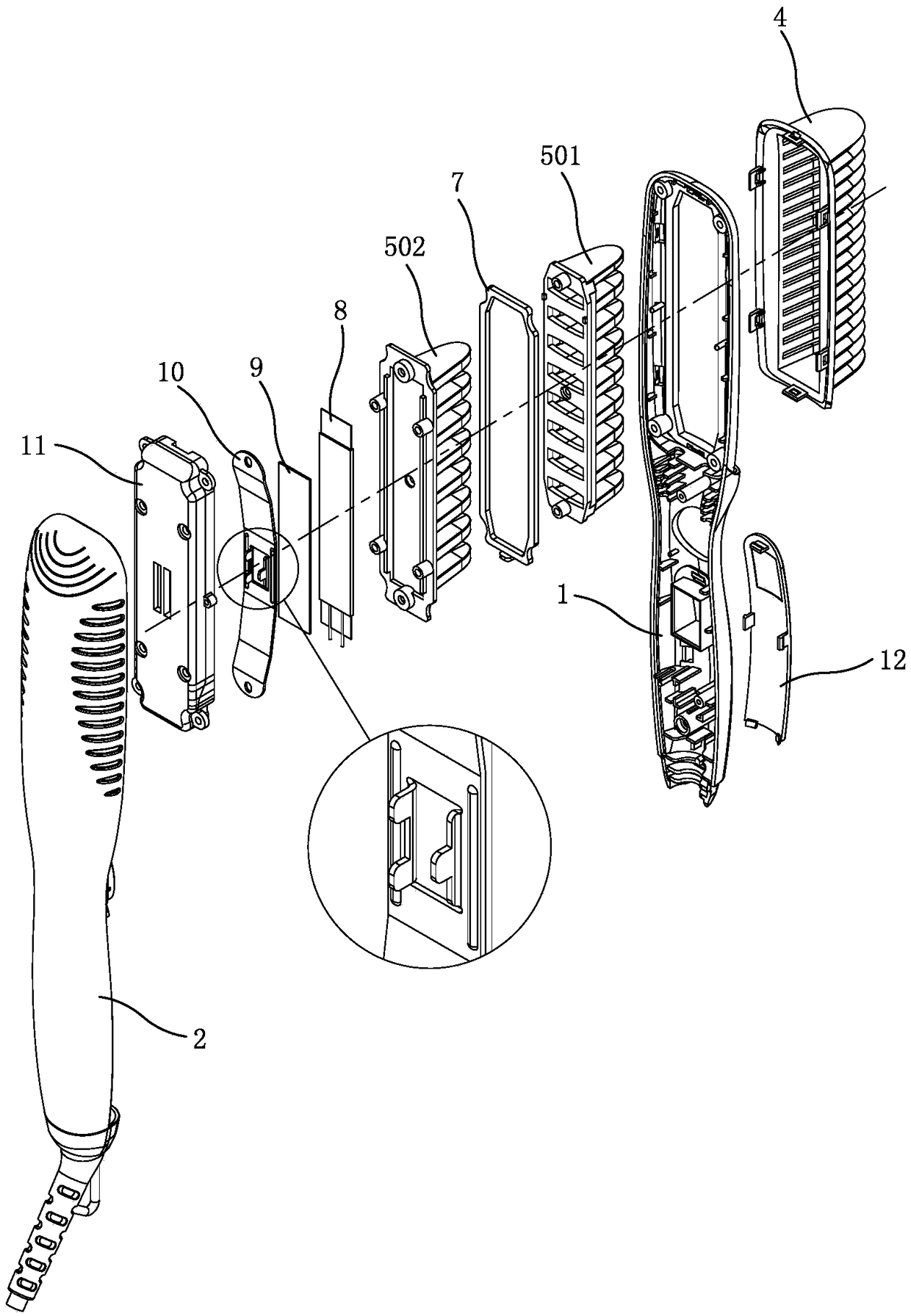

[0019] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1-Figure 7 As shown, the upper casing 1 and the lower casing 2 of the electric heating comb are fastened to form a main casing, one side of the main casing is a handle, and the other side is a comb head, and the handle on one side of the comb head is located at the main casing. There is a button assembly 3, the comb tooth end of the comb tooth assembly 5 at the comb head extends into the comb tooth case 4, the comb tooth case is provided with comb holes arranged at an even distance, the bottom shell mouth of the comb tooth case and the upper shell The mouth of the casing is fastened, the handle of the main casing is provided with a circuit board 6, and the button assembly is arranged on the circuit board. Its features are as follows: the comb assembly includes upper comb teeth 501, lower comb teeth 502, ceramic heating element 8, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap