Table frame capable of being quickly installed and lifting platform

A table frame and fast technology, which is applied to the legs of general furniture, desks with variable table heights, tables, etc. It can solve the problems of cumbersome assembly steps, large space occupied by the lifting platform, and unassembled lifting platform, etc., to achieve convenient operation The effect of quickness and simplification of assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

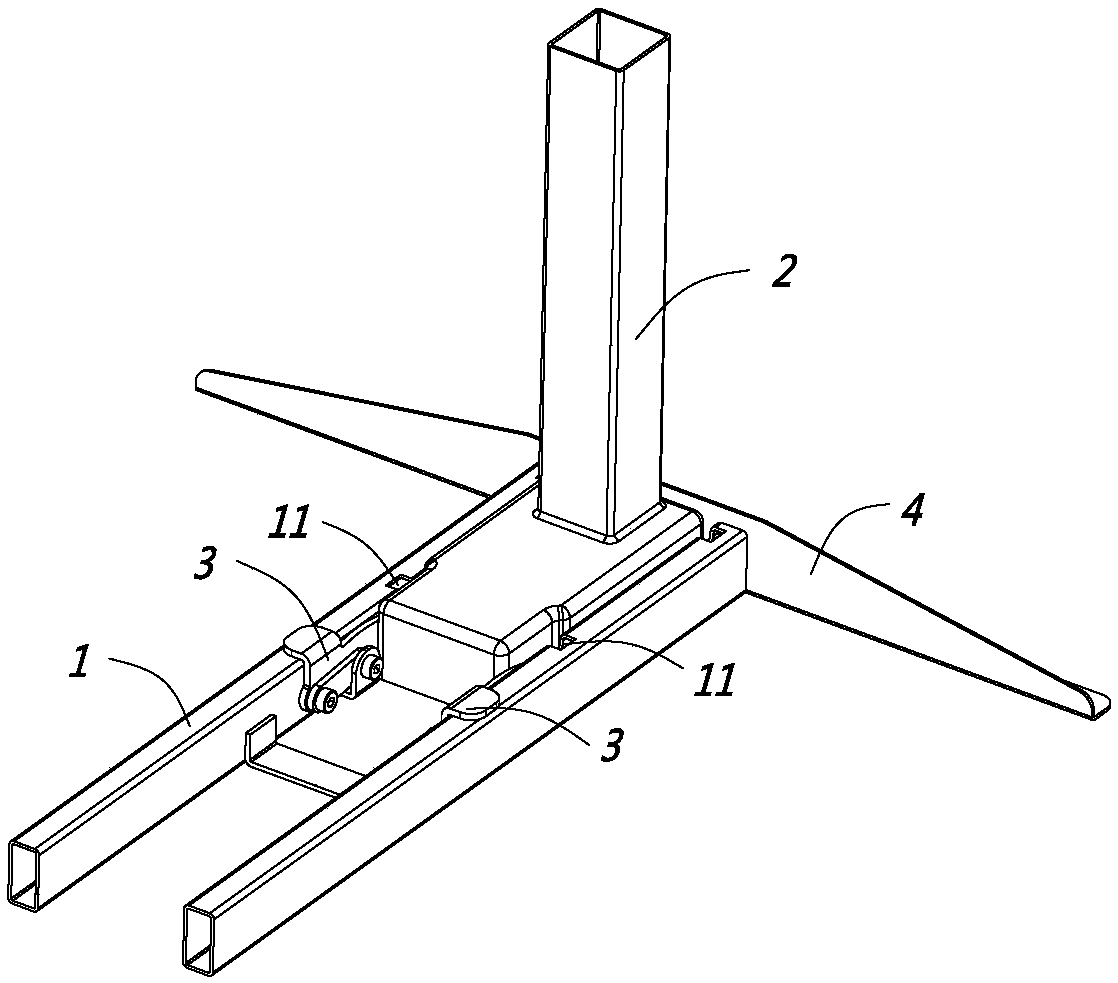

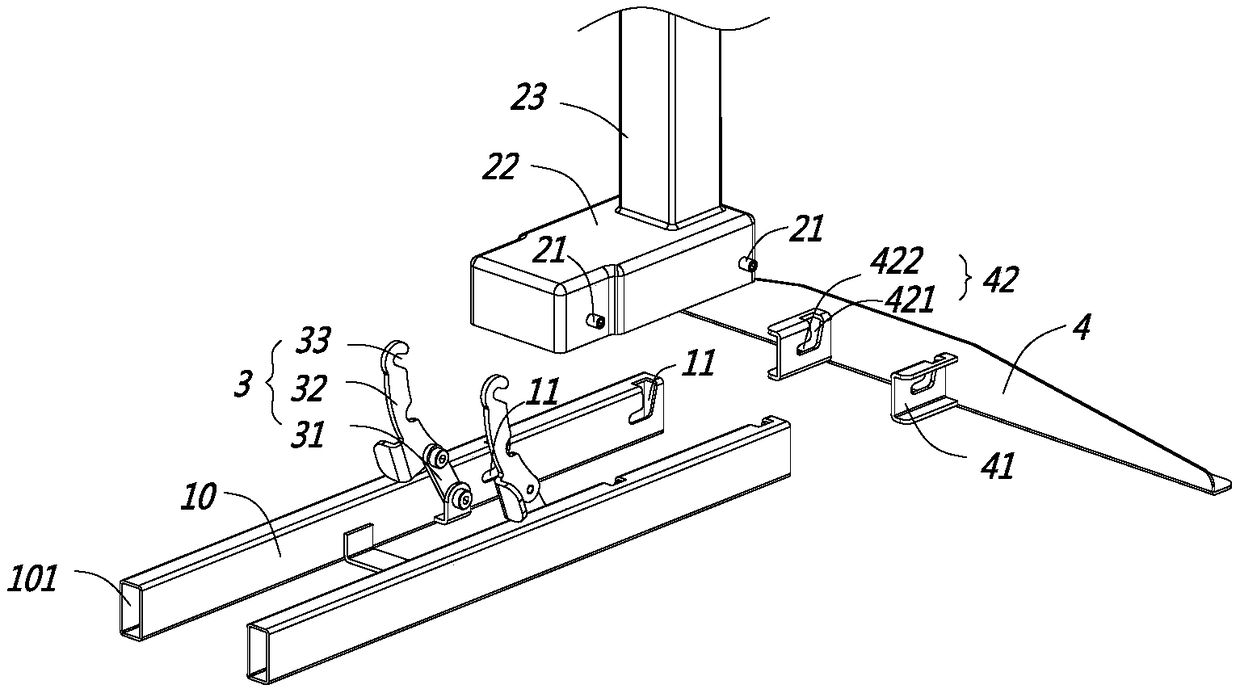

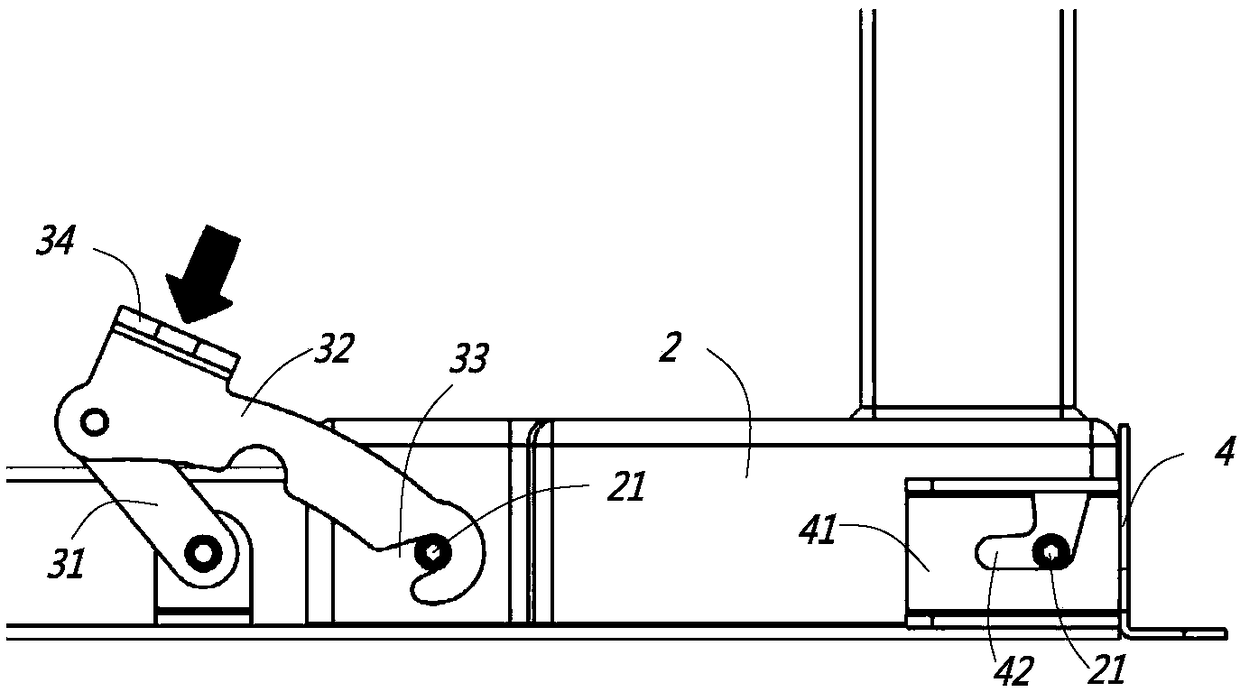

[0033] Such as Figure 1 to Figure 5 As shown, this embodiment discloses a table frame for quick installation, including a beam 1. For the convenience of description, the length direction of the beam 1 in this embodiment is defined as the transverse direction, and the width direction is defined as the longitudinal direction. The beam 1 A lifting column 2 is installed on it, and a locking groove 11 is provided on the crossbeam 1. The locking groove 11 includes a first insertion section 111 and a first locking section 112 that communicate with each other. The lifting column 2 is provided with a locking pin 21 , the locking member 3 is movably installed on the beam 1, and the locking member 3 includes an unlocked state and a locked state. In the unlocked state, the lock pin 21 is loaded from the first insertion section 111 and enters the first locking section 112. In the locked state Next, the locking member 3 engages with the locking pin, and limits the locking pin 21 in the fir...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the locking piece is not installed on the crossbeam by rotation, but the locking piece can be slidably installed on the crossbeam. When the lock pin enters the first locking section, the consumer can slide the locking piece. The locking piece and the outer wall of the locking pin are in conflict with each other to achieve snap-in, so that the locking pin is limited in the first locking section. As for how the locking piece is kept in the locked state, a button hole can be set on the beam, and a button hole can be set on the locking piece. Buckle, when the locking member slides to the locked position, the buckle is inserted into the buckle hole, of course, other fixing methods can also be used, which are not exhaustive here.

Embodiment 3

[0056] This embodiment is an elevating platform, including a table top and a table frame, wherein the table frame adopts the table frame of Embodiment 1 or Embodiment 2 or an embodiment equivalent thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com