Tea tray machine and heating control method thereof

A technology of a tea tray machine and a heating device, which is applied to the field of daily drinking utensils, can solve the problems of inability to accurately judge whether a teapot is located in the tea tray machine, inability to realize intelligent control, waste of resources, etc., achieving simple structure, preventing safety problems and resource waste, Realize the effect of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

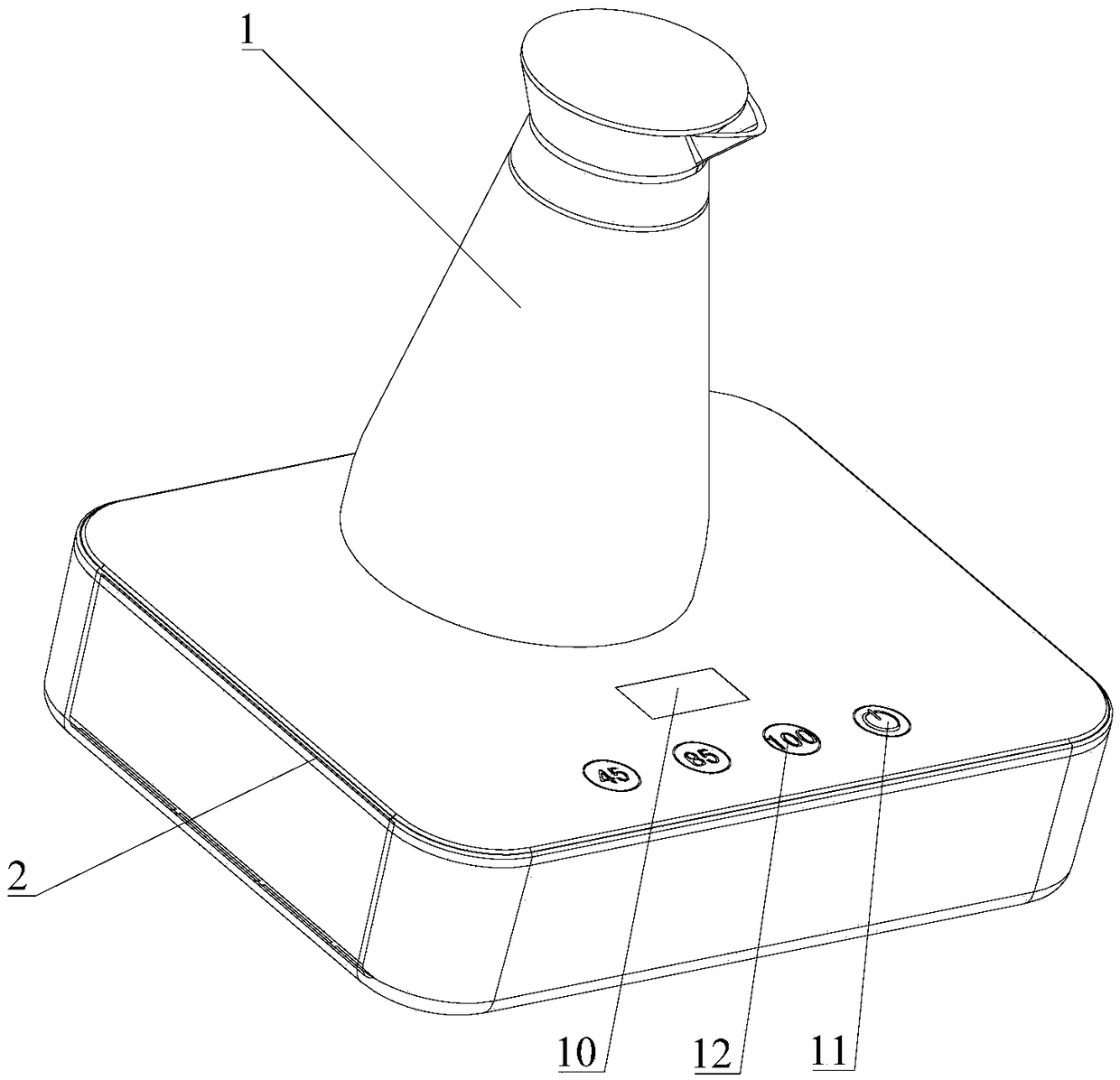

[0042] Please refer to figure 1 , Embodiment 1 of the present invention is: a tea tray machine, including a base 2 and a teapot 1 .

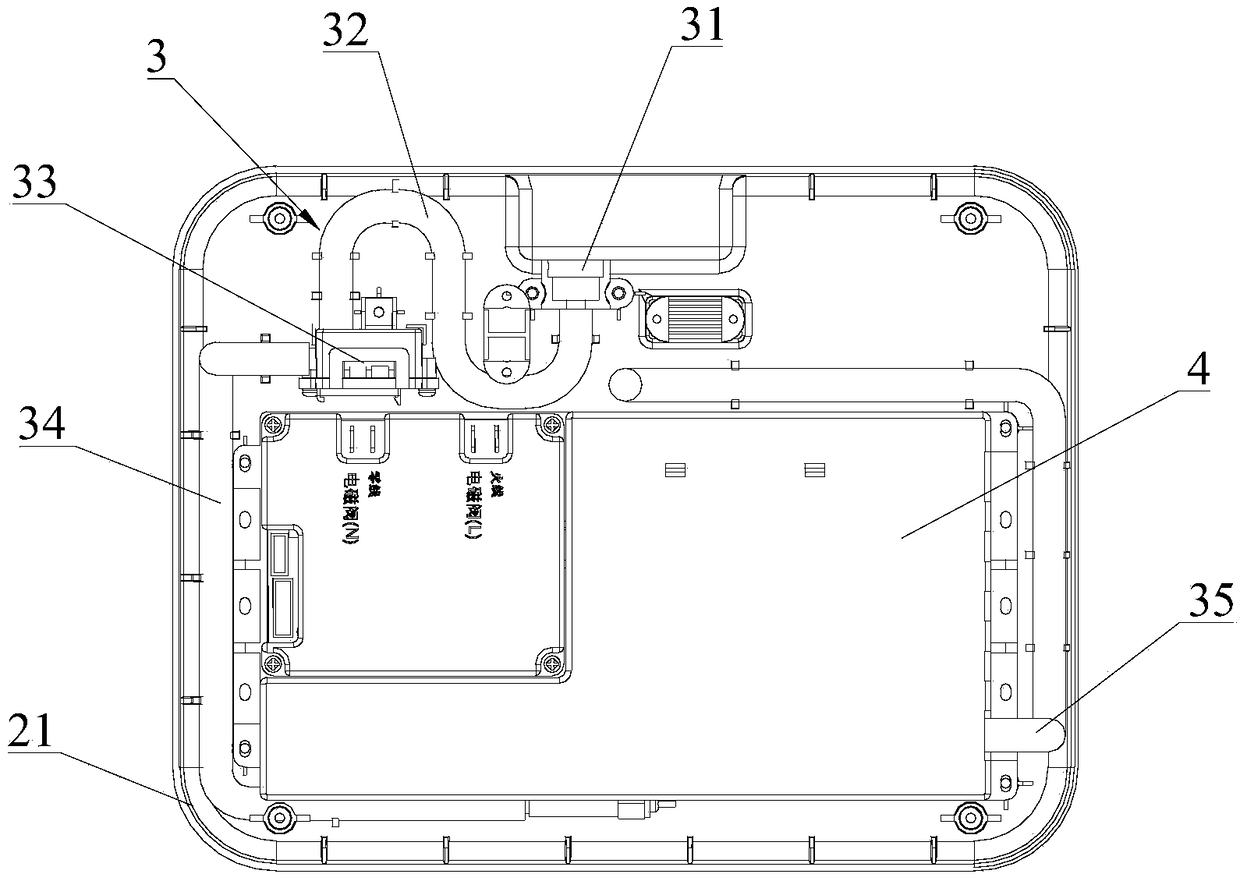

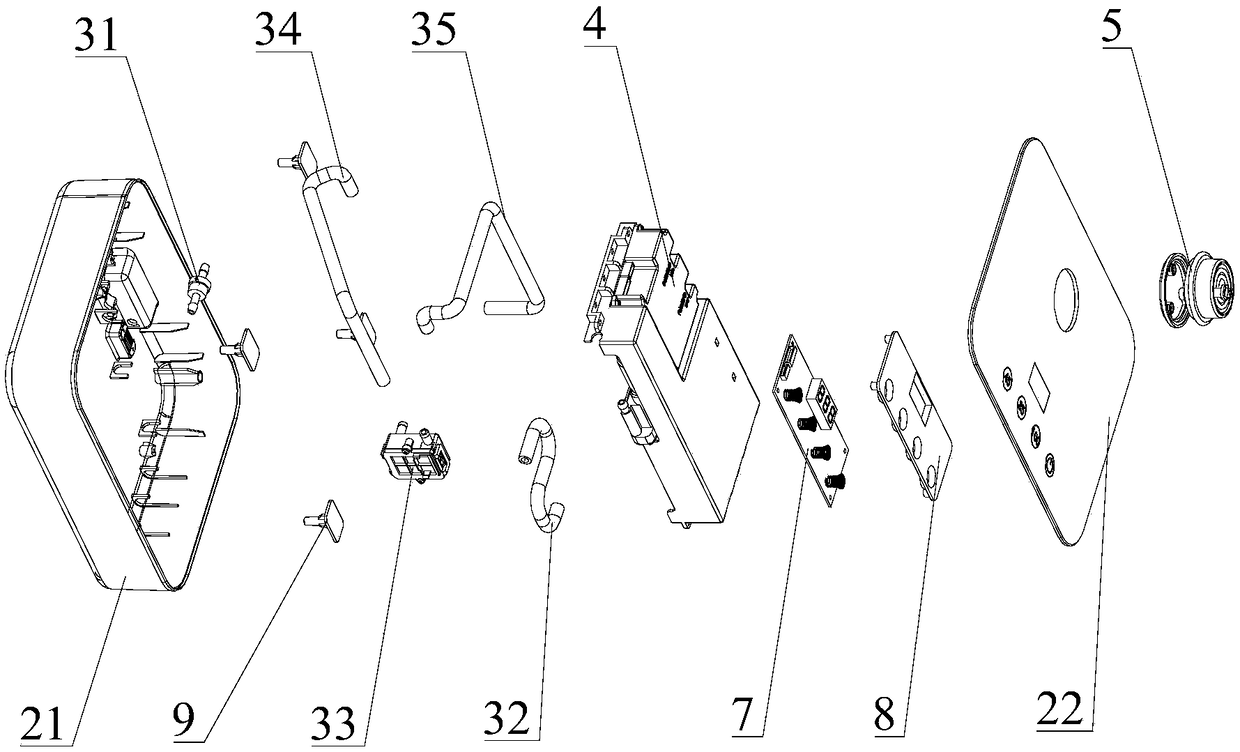

[0043] Such as figure 2 with image 3 As shown, the base 2 includes a casing 21 and a glass panel 22 , the glass panel 22 is covered on the casing 21 and forms a closed space together with the casing 21 . Specifically, the glass panel 22 is fixed on the shell 21 through the glass panel fixing plate 9 and screws, and waterproof glue, such as 3M glue, is bonded between the periphery of the glass panel 22 and the shell 21, so that the glass can be strengthened. The panel 22 also plays a waterproof role.

[0044] A water inlet device 3 , a heating device 4 and a main control board 7 are arranged in the airtight space formed by the housing 21 and the glass panel 22 , and the main control board 7 is fixed on the inner side of the glass panel 22 by the main control board fixing plate 8 . The upper side of the glass panel 22 is provided with a wat...

Embodiment 2

[0049] Such as Figure 5 As shown, this embodiment is improved on the basis of Embodiment 1: a temperature sensor 14 is also arranged in the teapot of this embodiment, and the two ends of the temperature sensor 14 are respectively connected to the other end of the water inlet coupler 6. two terminals. The water inlet coupler 6 includes multiple pairs of positive and negative terminals, the temperature sensor 14 and the resistor are respectively connected to different terminals, the two are located in different circuit loops, and the circuit signals between the two do not interfere with each other .

[0050] When the water inlet coupler 6 of the teapot 1 is connected with the water outlet coupler 5 of the base 2, the temperature sensor is energized, and the main control board 7 can detect the signal of the temperature sensor, that is, the start-up condition is met, and the tea tray machine can start to work smoothly; The main control board 7 cannot detect the signal of the te...

Embodiment 3

[0052] This embodiment is: a heating control method for a tea tray machine, comprising the following steps:

[0053] S1. Press the switch button 11 on the base 2 of the tea tray machine, the chip on the main control board 7 will start scanning to see if the voltage at both ends of the resistor can be scanned, if the voltage at both ends of the resistor cannot be scanned, disconnect the tea tray machine power input; if the voltage across the resistor can be detected, the tea tray machine is normally turned on.

[0054] S2. Press one of the temperature control buttons 12, the chip of the main control board 7 sends a corresponding control signal according to the received signal: the main control board 7 controls the opening of the one-way valve 31, and at the same time controls the start of the water pump and the thick film heating body to make the base 2 Inlet water and heat. When different temperature control buttons 12 are selected, the main control board 7 controls the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com