Separating device for gas component

A gas component and separation device technology, applied in the field of separation, can solve problems such as difficult maintenance, complicated operation, and high energy consumption, and achieve the effects of saving manpower, preventing pressure film rupture, and protecting instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

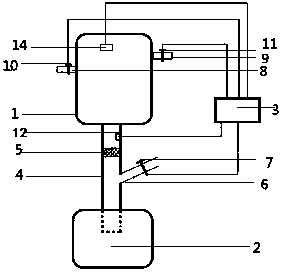

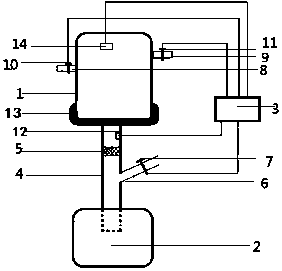

[0027] Such as figure 1 figure 2 As shown, the separation device for gas components includes a gas storage tank 1 and a liquid storage tank 2 connected to the bottom of the gas storage tank 1. A pressure sensor 14 is installed inside the tank body of the gas storage tank 1, and a gas pressure sensor 14 is installed on the gas storage tank 1. The inlet pipe 8 and the outlet pipe 9 are respectively provided with an inlet pipe valve 10 and an outlet pipe valve 11 on the inlet pipe 8 and the outlet pipe 9, and the gas storage tank 1 and the liquid storage tank 2 are connected by a one-way permeation structure, and the one-way permeation The main part of the structure is an infusion pipeline 4, and the middle part of the infusion pipeline 4 is provided with a one-way membrane 5, which divides the infusion pipeline from top to bottom into the first part and the second part, which are located under the one-way membrane 5 One side of the infusion pipeline is connected with a pressur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap