An umbrella-shaped antenna metal mesh surface holding sewing device

An umbrella antenna and metal mesh technology, which is applied in the field of the umbrella antenna metal mesh surface retaining and sewing device, can solve the problems of large difference in the shape of the sector mesh surface, uneven mesh surface tension, lack of mesh surface tension, etc., and achieves high The effect of transferring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

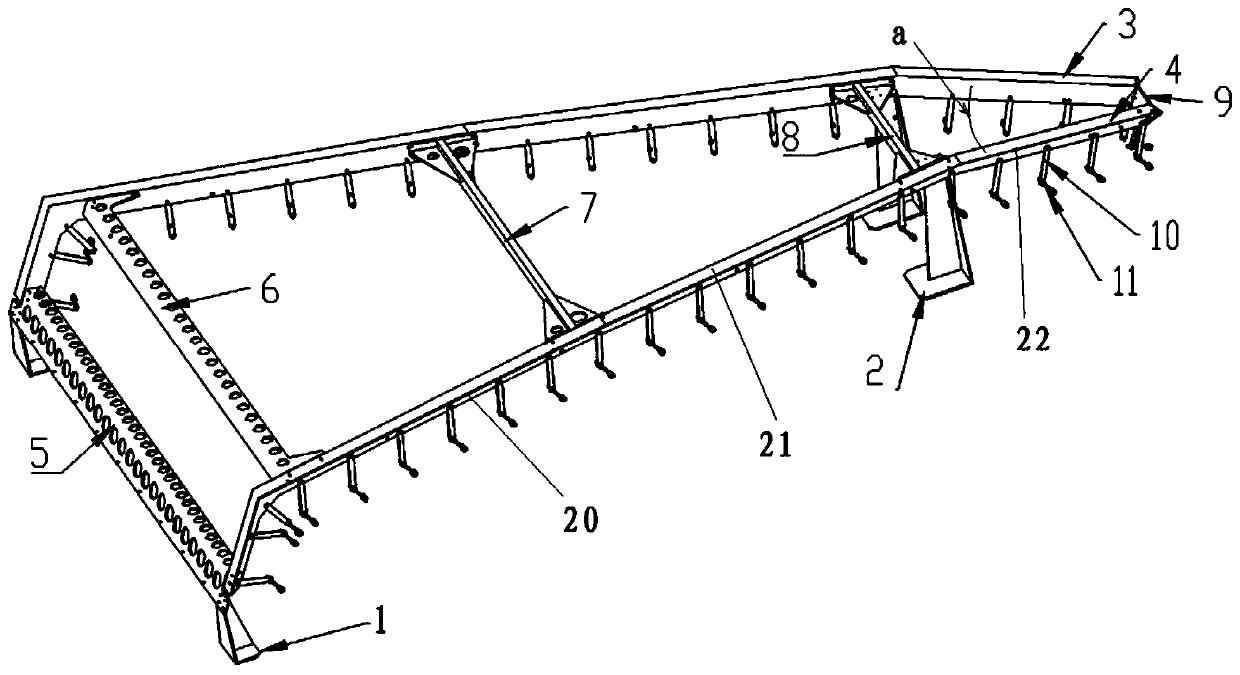

[0024] like figure 1 Shown is a schematic diagram of the mesh surface holding sewing device. It can be seen from the figure that an umbrella-shaped antenna metal mesh surface holding sewing device is characterized in that it includes a first support member 1, a second support member 2, and a first simulation rib 3 , the second simulated rib 4, the first beam 5, the second beam 6, the third beam 7, the fourth beam 8, the fifth beam 9, the tension cable support bar 10 and the tension cable locker 11;

[0025] Wherein, the first simulated rib 3 and the second simulated rib 4 are horizontally placed at an angle a; the first crossbeam 5, the second crossbeam 6, the third crossbeam 7, the fourth crossbeam 8 and the fifth crossbeam 9 are fixedly installed on the first Between the simulated rib 3 and the second simulated rib 4; and the first beam 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com