A kind of intelligent manufacturing device based on industrial robot and using method

An industrial robot and intelligent manufacturing technology, applied in the field of manufacturing equipment, can solve problems such as inability to grind, unsafe, uneven grinding, etc., and achieve the effect of preventing excessive temperature damage and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

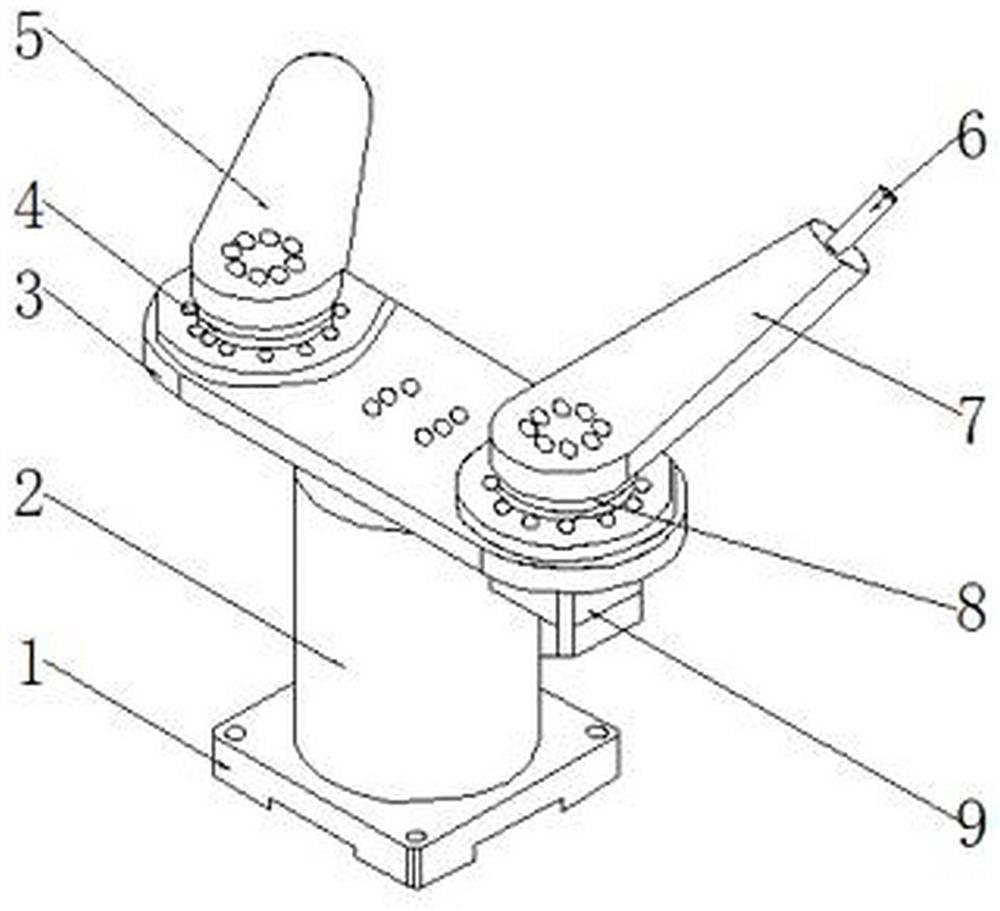

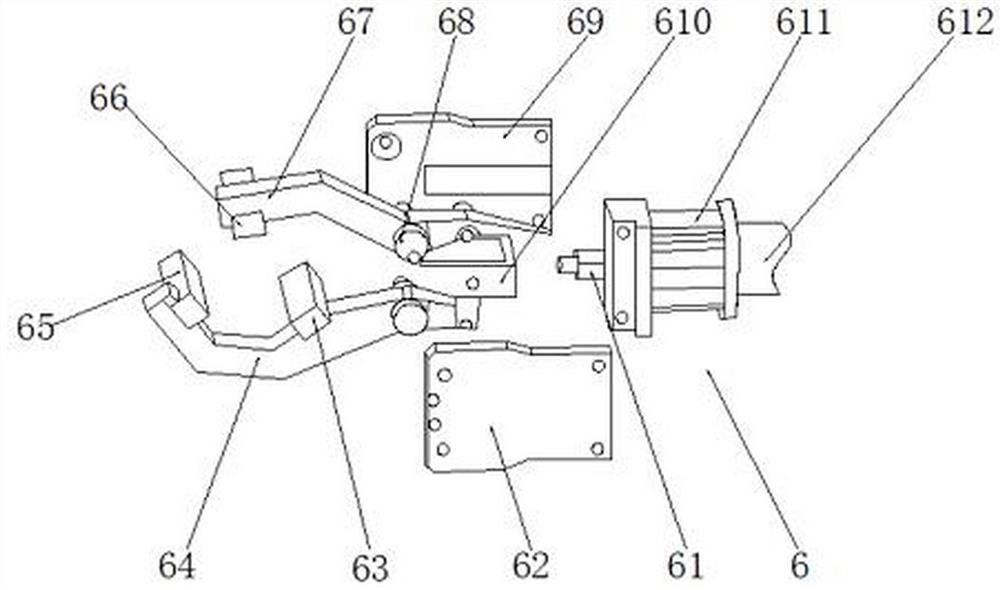

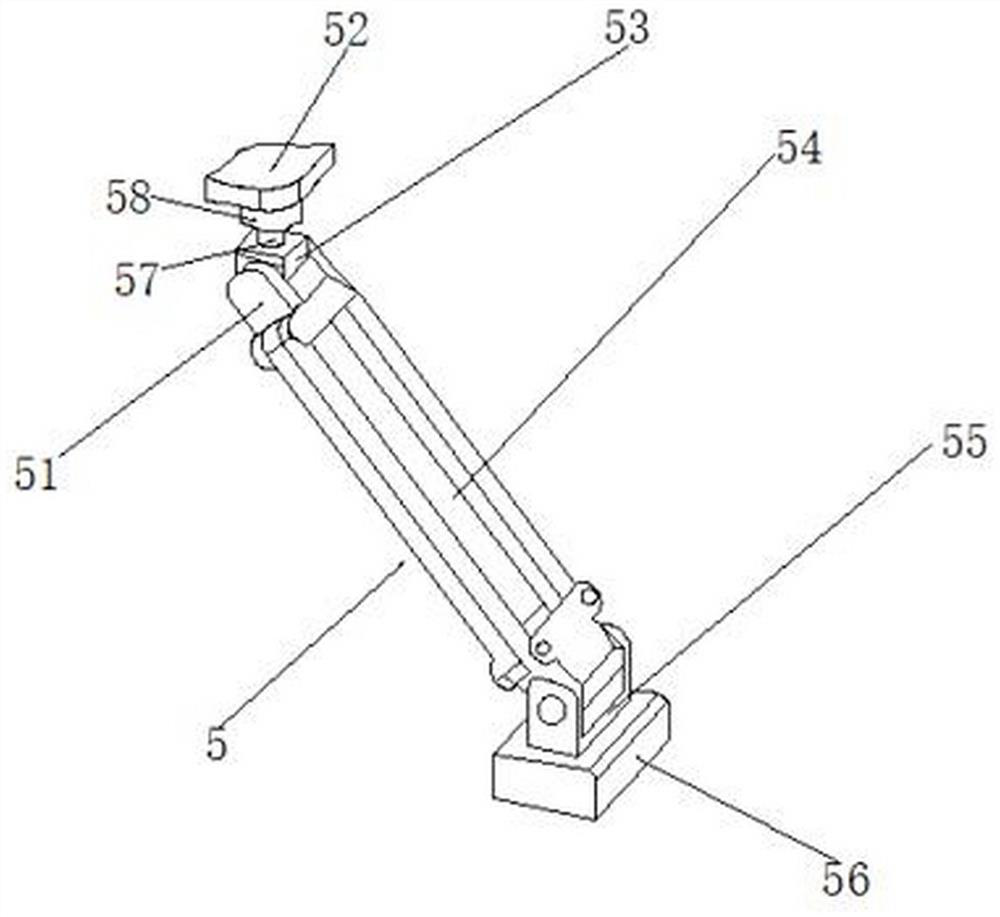

[0029] see Figure 1-5, The present invention provides an intelligent manufacturing device based on industrial robots, including a base 1, a controller 2, a first connecting plate 3, a first turntable 4, a first swing arm 5, a clamp device 6, a second swing arm 7, a first Two turntables 8, operation panel 9, first connecting shaft 61, first baffle plate 62, first cushion block 63, first clamp handle 64, infrared emitter 65, second cushion block 66, second clamp handle 67, nut 68. The second baffle plate 69, the first U-shaped connecting plate 610, the first connecting column 611, the second connecting shaft 612, the second U-shaped connecting plate 51, the cutter device 52, the rotating shaft 53, the second connecting column 54, The third U-shaped connecting plate 55, connecting block 56, angle sensor 57, infrared receiver 58, draw-in slot 521, cutting knife 522, second connecting plate 523, spring 524, third rotating disk 525 and the third connecting plate 526, circuit plate...

Embodiment 2

[0031] An intelligent manufacturing device based on an industrial robot, including a base 1, a controller 2, a first connecting plate 3, a first turntable 4, a first swing arm 5, a fixture device 6, a second swing arm 7, a second turntable 8, Operation panel 9, first connecting shaft 61, first baffle plate 62, first spacer 63, first clamp 64, infrared emitter 65, second spacer 66, second clamp 67, nut 68, second Baffle plate 69, first U-shaped connecting plate 610, first connecting column 611, second connecting shaft 612, second U-shaped connecting plate 51, cutter device 52, rotating shaft 53, second connecting column 54, third U-shaped Connecting plate 55, connecting block 56, angle sensor 57, infrared receiver 58, card slot 521, cutting knife 522, second connecting plate 523, spring 524, third turntable 525 and third connecting plate 526, circuit board 21 and cover 22, the base 1 is fixedly connected with a controller 2; the other end of the controller 2 is fixedly connecte...

Embodiment 3

[0034] An intelligent manufacturing device based on an industrial robot, including a base 1, a controller 2, a first connecting plate 3, a first turntable 4, a first swing arm 5, a fixture device 6, a second swing arm 7, a second turntable 8, Operation panel 9, first connecting shaft 61, first baffle plate 62, first spacer 63, first clamp 64, infrared emitter 65, second spacer 66, second clamp 67, nut 68, second Baffle plate 69, first U-shaped connecting plate 610, first connecting column 611, second connecting shaft 612, second U-shaped connecting plate 51, cutter device 52, rotating shaft 53, second connecting column 54, third U-shaped Connecting plate 55, connecting block 56, angle sensor 57, infrared receiver 58, card slot 521, cutting knife 522, second connecting plate 523, spring 524, third turntable 525 and third connecting plate 526, circuit board 21 and cover 22, the base 1 is fixedly connected with a controller 2; the other end of the controller 2 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com