Tire face tread pattern structure

A pattern structure and tire tread technology, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve problems such as inability to cope with light off-road roads, to ensure off-road performance, improve skid resistance, Increase the effect of edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

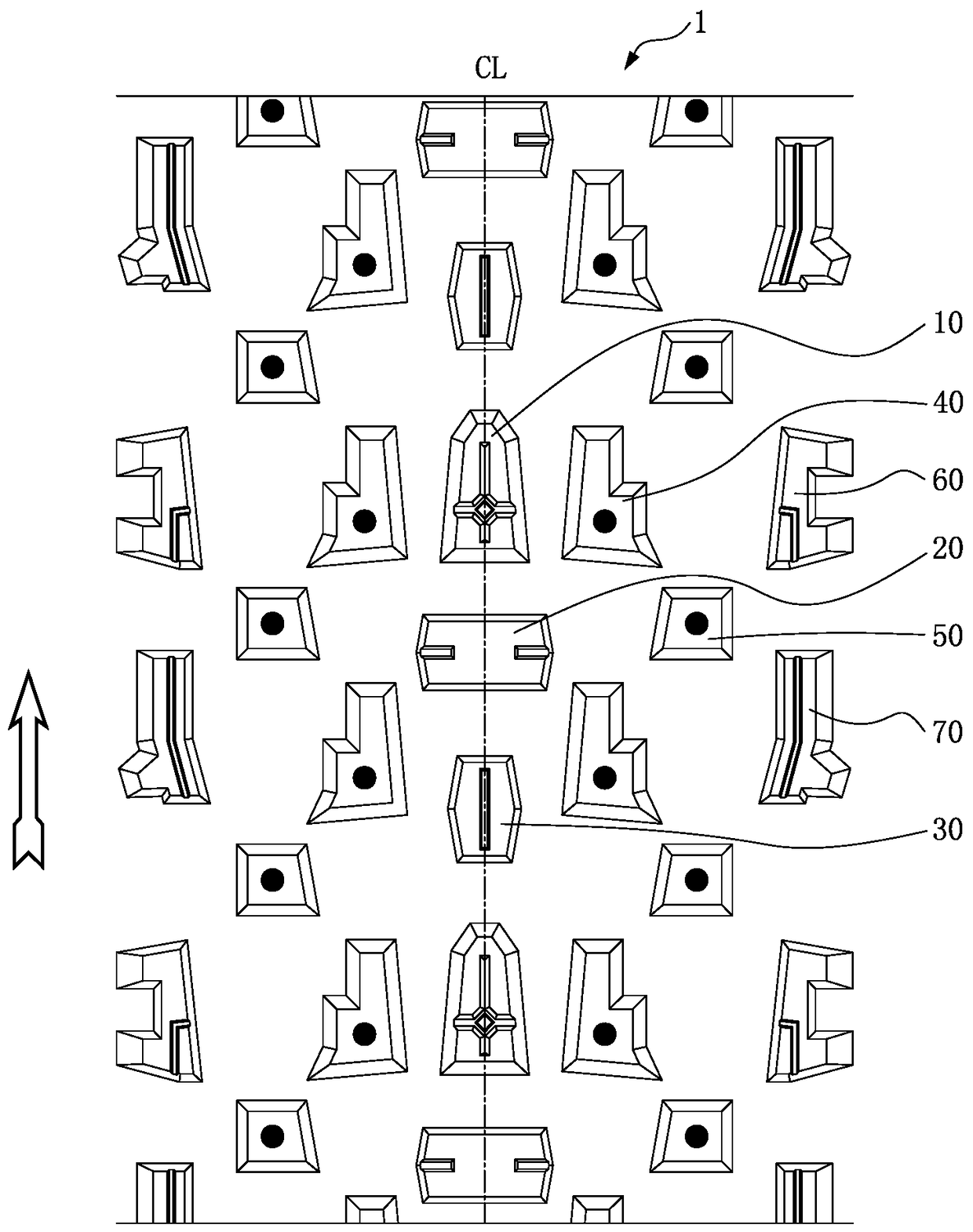

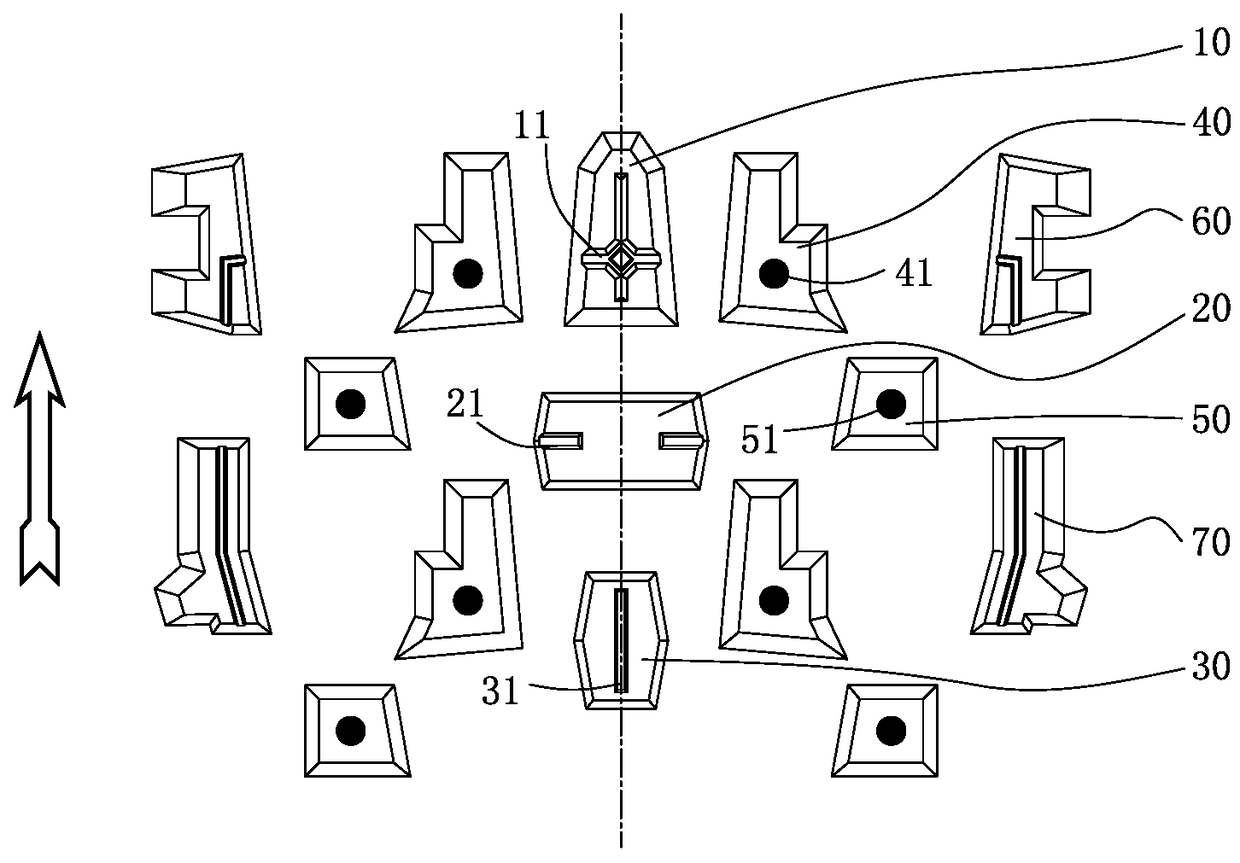

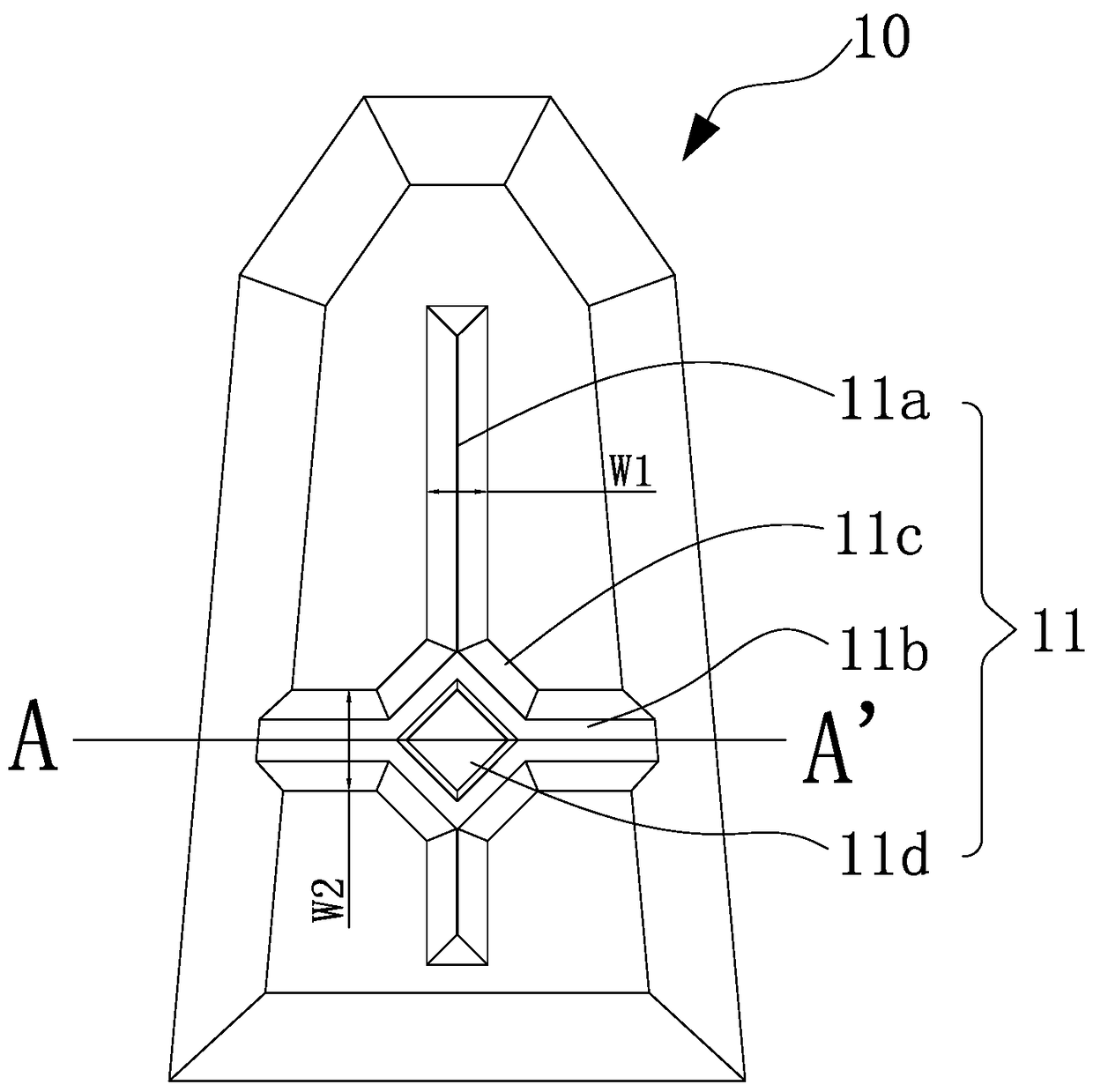

[0044] Such as Figure 1 to Figure 7 As shown, the present invention discloses a tire tread pattern structure, wherein: the vertical direction is set as the tire radial direction, the lateral direction is set as the tire axial direction, the single dotted line represents the equatorial plane, and the arrow points to the tire's running direction. The end of the pattern block pointing to the driving direction represents the front end, the end of the pattern block opposite the traveling direction represents the rear end, the end of the pattern block close to the tread centerline CL represents the inner end, and the end of the pattern block away from the tread centerline CL represents the outer end. In addition, the terms "first", "second", "third", etc. are only used to describe a feature, and should not be construed as indicating or implying the quantity of the feature.

[0045] Such as figure 1 , 2 As shown, the tire tread 1 of the present invention is provided with a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com