A front extension panel installation structure of an auxiliary instrument panel

A sub-dashboard and installation structure technology, applied in the field of the installation structure of the front extension panel of the sub-dashboard, can solve the problems of lowering the quality of the vehicle model, production complaints, and difficult assembly, so as to save assembly time, improve visual perception, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

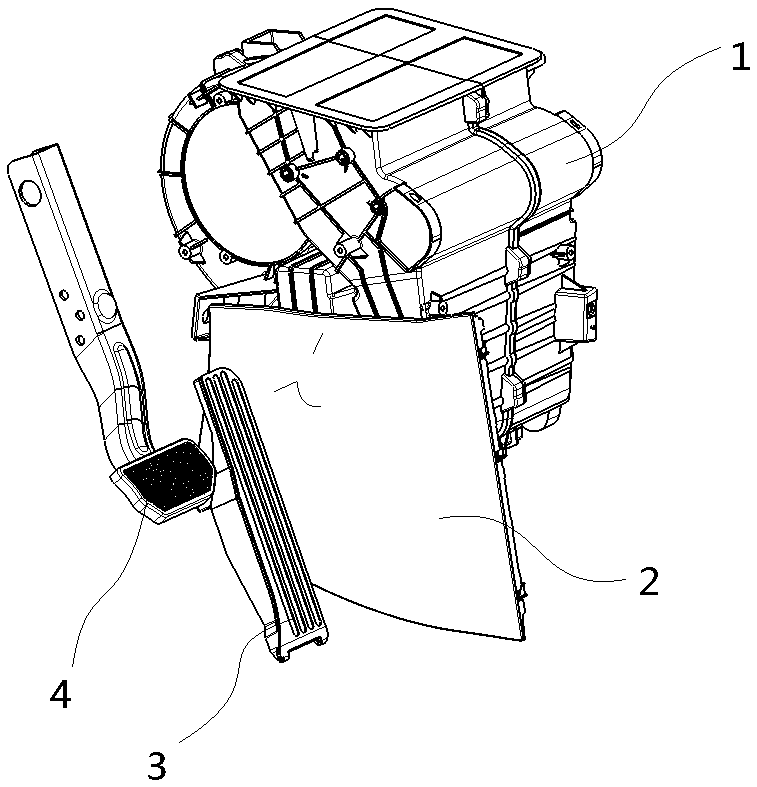

[0022] Such as figure 1 In the shown embodiment, a sub-dashboard front extension panel installation structure includes an air conditioner HVAC 1 and a sub-dashboard front extension panel 2 , and the sub-dashboard front extension panel is arranged on the side of the air-conditioning HVAC close to the brake pedal 4 and the accelerator pedal 3 .

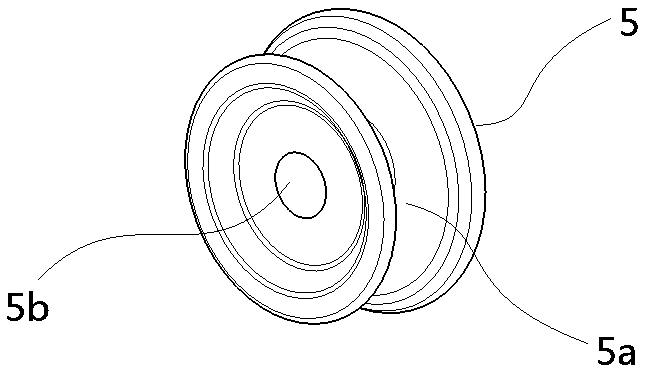

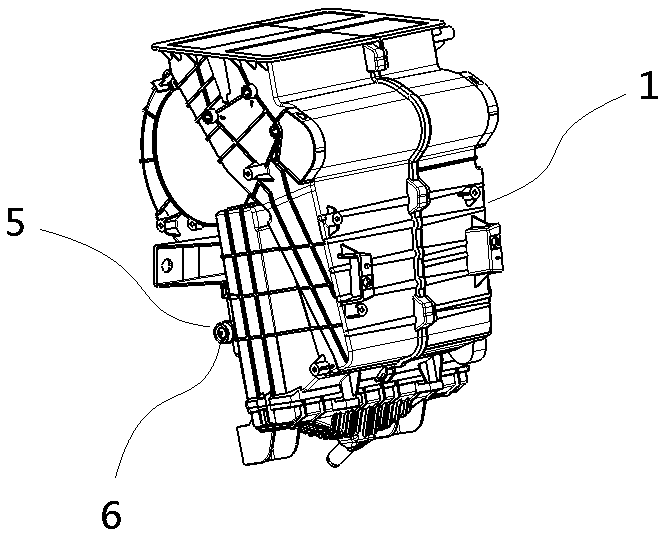

[0023] combine figure 2 As shown, the air conditioner HVAC is provided with a mounting bracket 5 on the side of the front extension panel of the auxiliary instrument panel, and the mounting bracket is made of POM material. The side surface of the air conditioner HVAC is provided with a threaded hole, and a screw 6 for fixing the mounting bracket is provided in the threaded hole. The mounting bracket is circular, and the center of the mounting bracket is provided with a through hole 5b, and the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com