A kind of agv trolley with good stability

A stable performance, small car technology, applied in the field of warehouse cargo transportation, can solve the problems of large car body damage, low anti-collision performance, time-consuming and labor-intensive, etc., to achieve the effect of reducing collision wear, prolonging service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

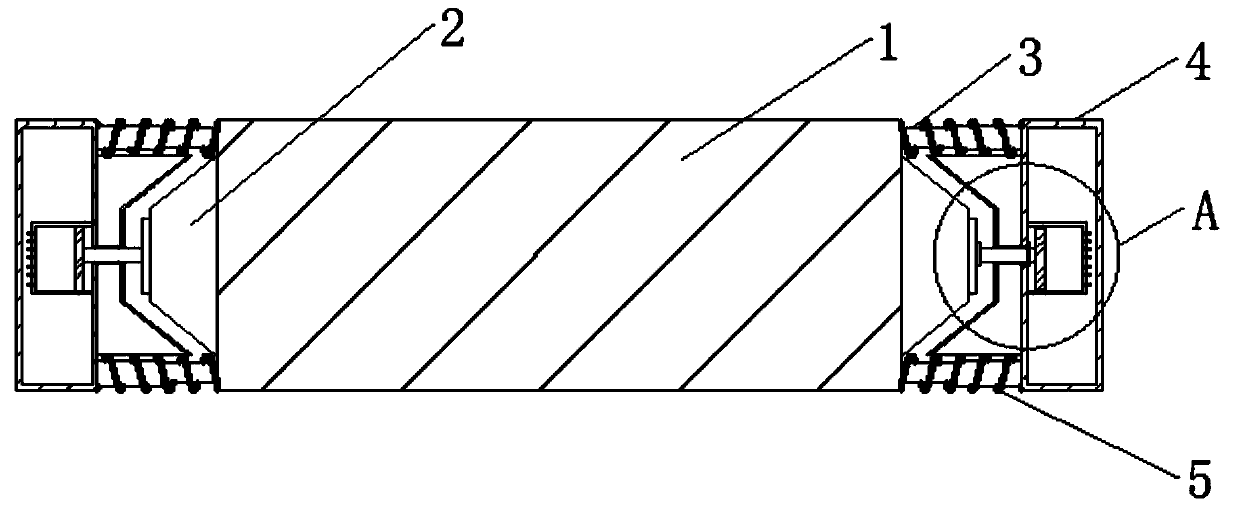

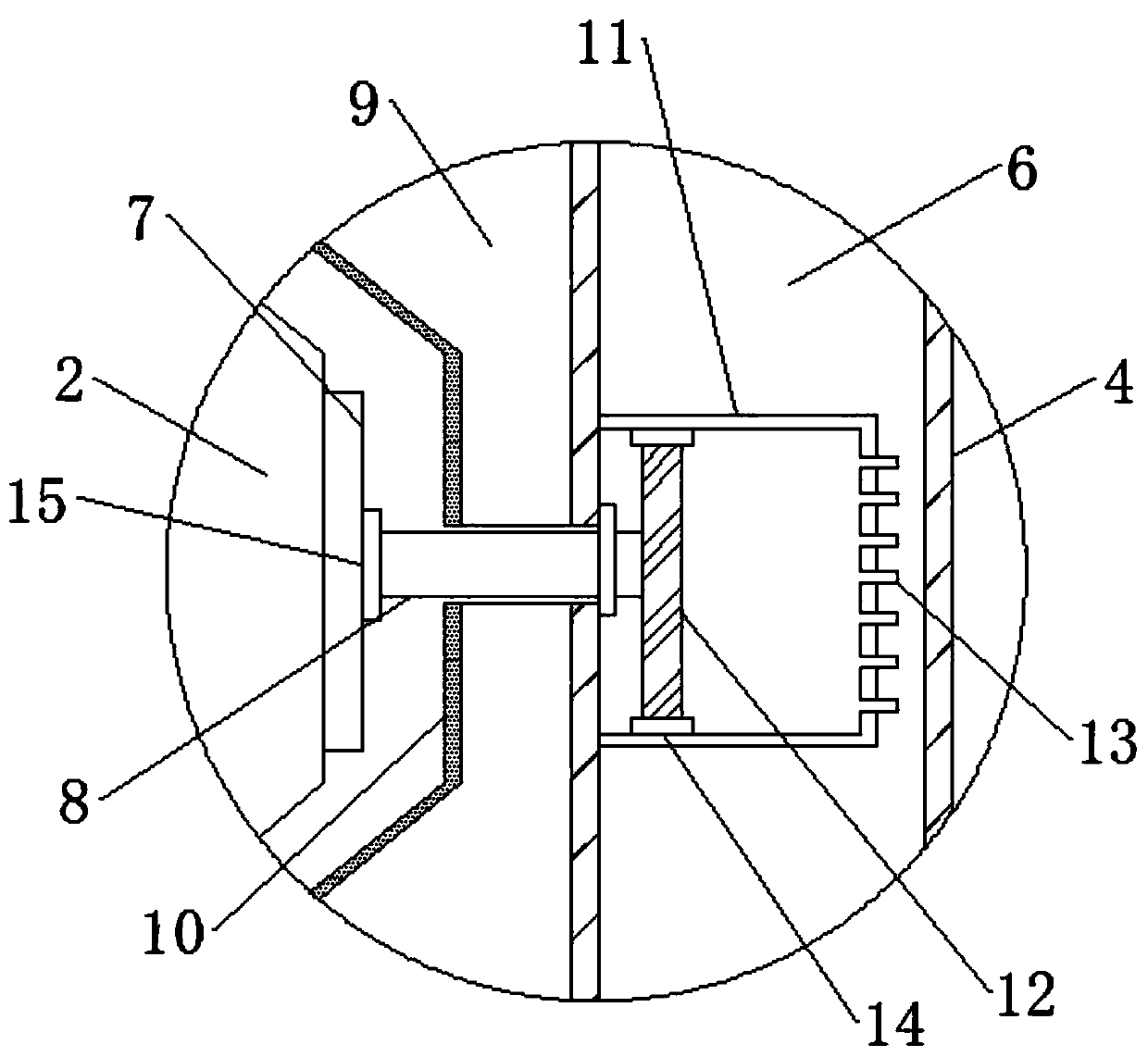

[0026] see Figure 1-2 , an AGV trolley with good stability, including a car body 1, fixed blocks 2 are fixedly connected to the left and right ends of the car body 1, and a buffer plate 4 is provided on the side of the fixed block 2 away from the car body 1, and the buffer plate 4 is connected to the car body 1 A pair of telescopic rods 3 are fixedly connected between the side walls, and the pair of telescopic rods 3 are respectively located on the upper and lower sides of the fixed block 2. The matched support plate 9 and the buffer plate 4 are provided with a cavity 6, and the inner wall of the end of the buffer plate 4 close to the support plate 9 is fixedly connected with a piston cylinder 11, and the piston cylinder 11 is provided with a matching piston push plate 12, and a fixed block 2 One end close to the support plate 9 is fixedly connected with a connecting plate 7, and one end of the connecting plate 7 away from the fixed block 2 is fixedly connected with a piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com