a washing machine

A technology for washing machines and washing machine shells, applied in the field of washing machines, which can solve problems such as inability to clean, easy accumulation of dirt, increased bacteria in washing machines, etc., and achieve the effect of increasing volume and washing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, in order to discharge the water in the inner tub of the washing machine and to realize the normal washing by sealing the inner tub with water during the working process of the washing machine, the following settings are performed:

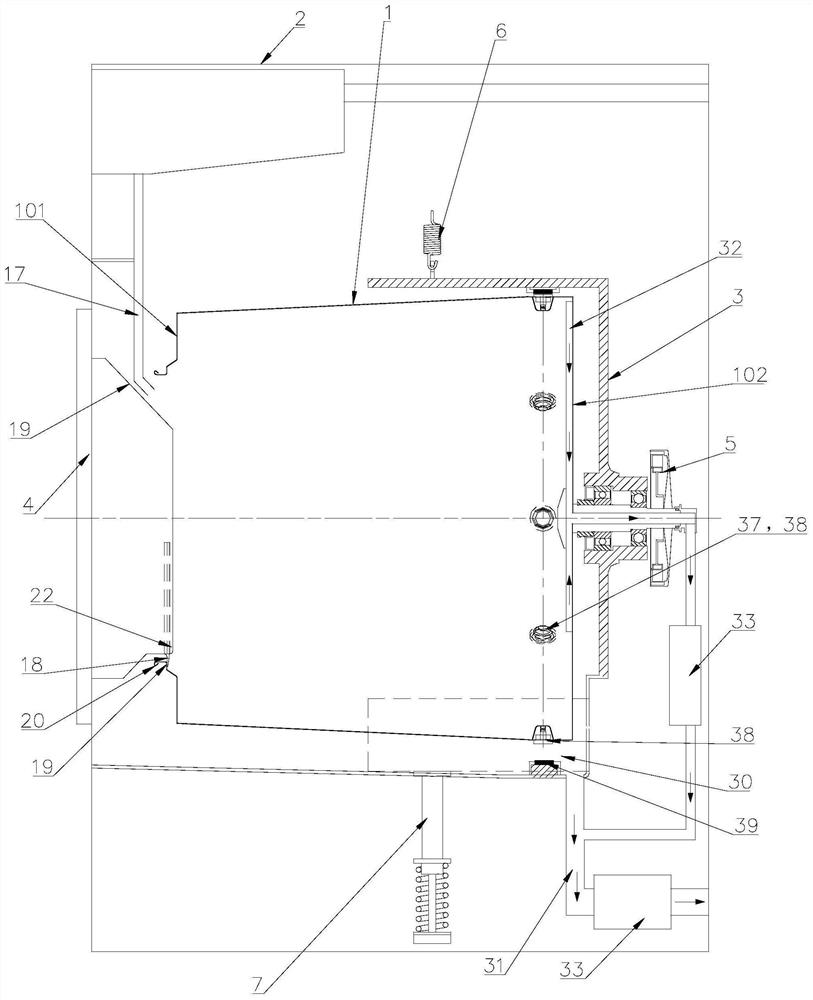

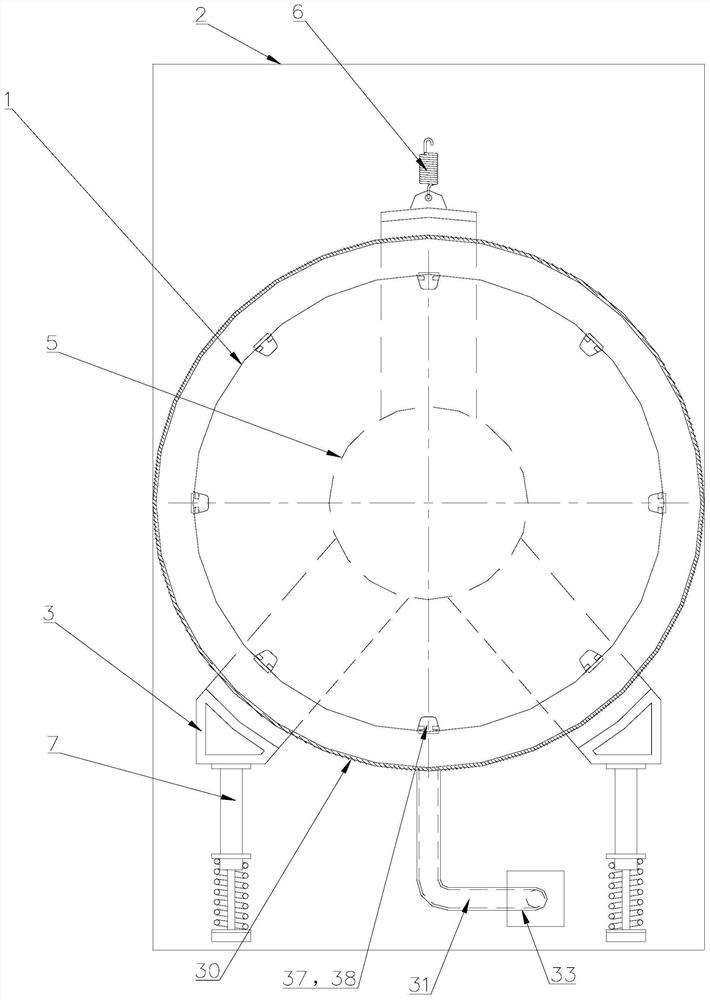

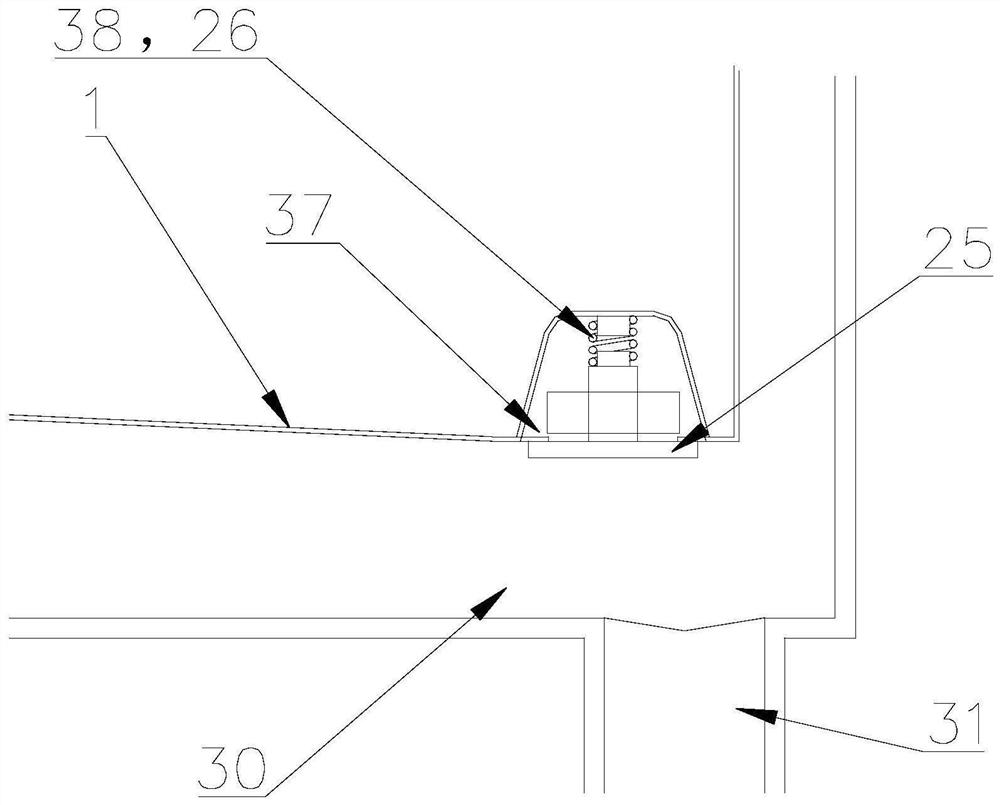

[0046] like figure 1 As shown, a drainage structure of a washing machine is installed in the washing machine shell 2 with an inner cylinder 1, the inner cylinder 1 is a conical cylinder with a small diameter at one end and a large diameter at the other end, and the large mouth end of the inner cylinder 1 is provided with a drainage channel 32 to drain the water. One end of the flow channel 32 communicates with the large mouth end of the inner tub 1 , and the other end passes through the inner tub 1 through the center of the large mouth end and communicates with the washing machine drain pipe 31 .

[0047] In the normal washing process of the drum washing machine, the inner drum 1 generally rotates at a low speed, and the ...

Embodiment 2

[0055] In this embodiment, a drainage method based on the washing machine described in the first embodiment above is introduced. The inner cylinder rotates at a certain speed, so that the washing water in the inner cylinder flows against the inner wall of the conical inner cylinder to the large mouth end under the action of centrifugal force, and the water flows into the inner cylinder. When the tub has a large mouth end, the drainage channel arranged along the large mouth end flows out from the center of the large mouth end of the inner tub, and flows out of the washing machine along the drain pipe, so that the washing water in the inner tub can be drained out.

[0056] Through the above method, in the normal washing state of the washing machine, the water flow in the inner drum is not affected by centrifugal force, and does not converge and flow toward the large mouth end of the inner drum. The flow channel flows and discharges outward, so that the water in the inner tube wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com