Washing machine

A technology of washing machine and washing machine shell, applied in the field of washing machine, to achieve the effects of preventing water leakage, increasing the volume of the inner cylinder, and clear design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

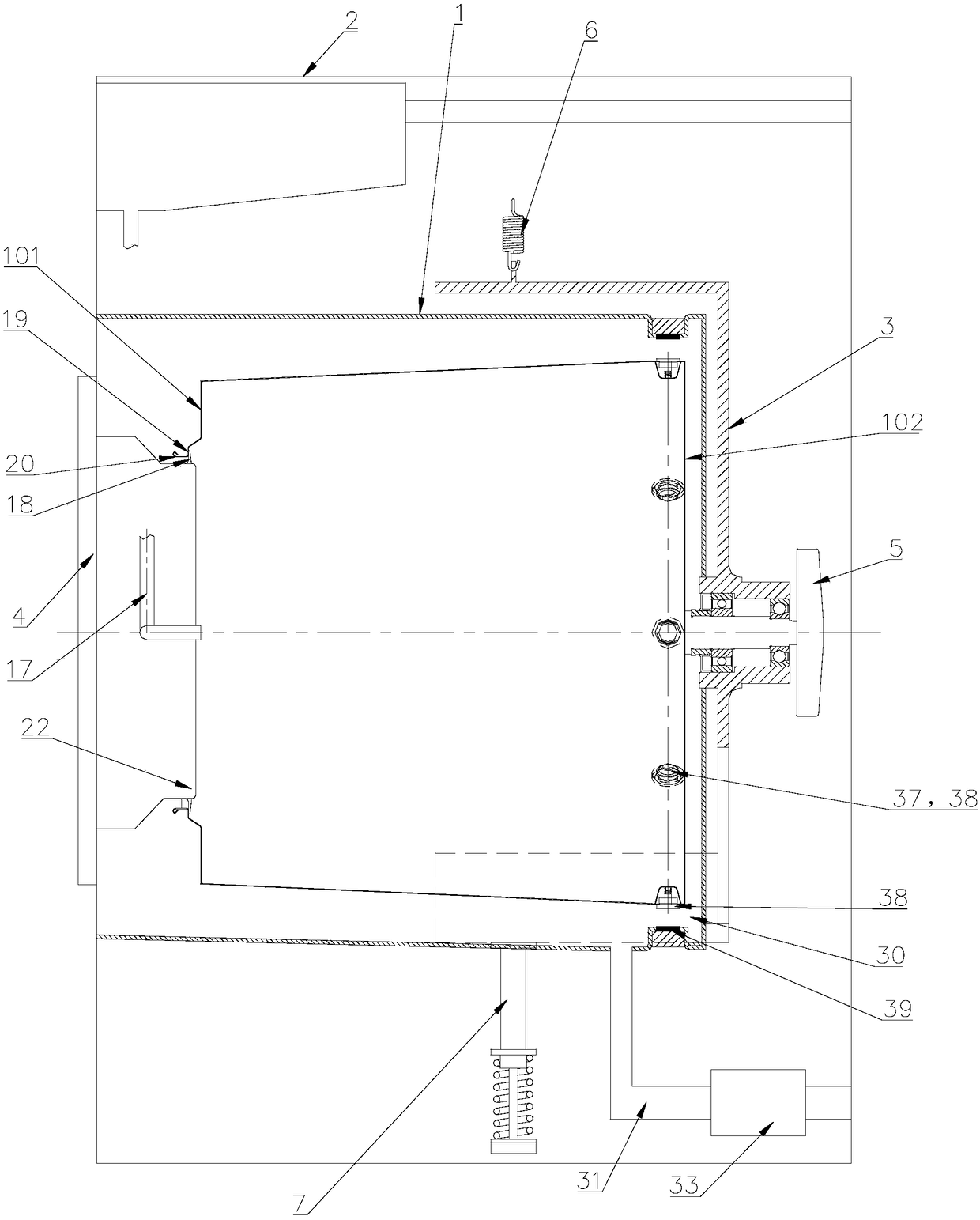

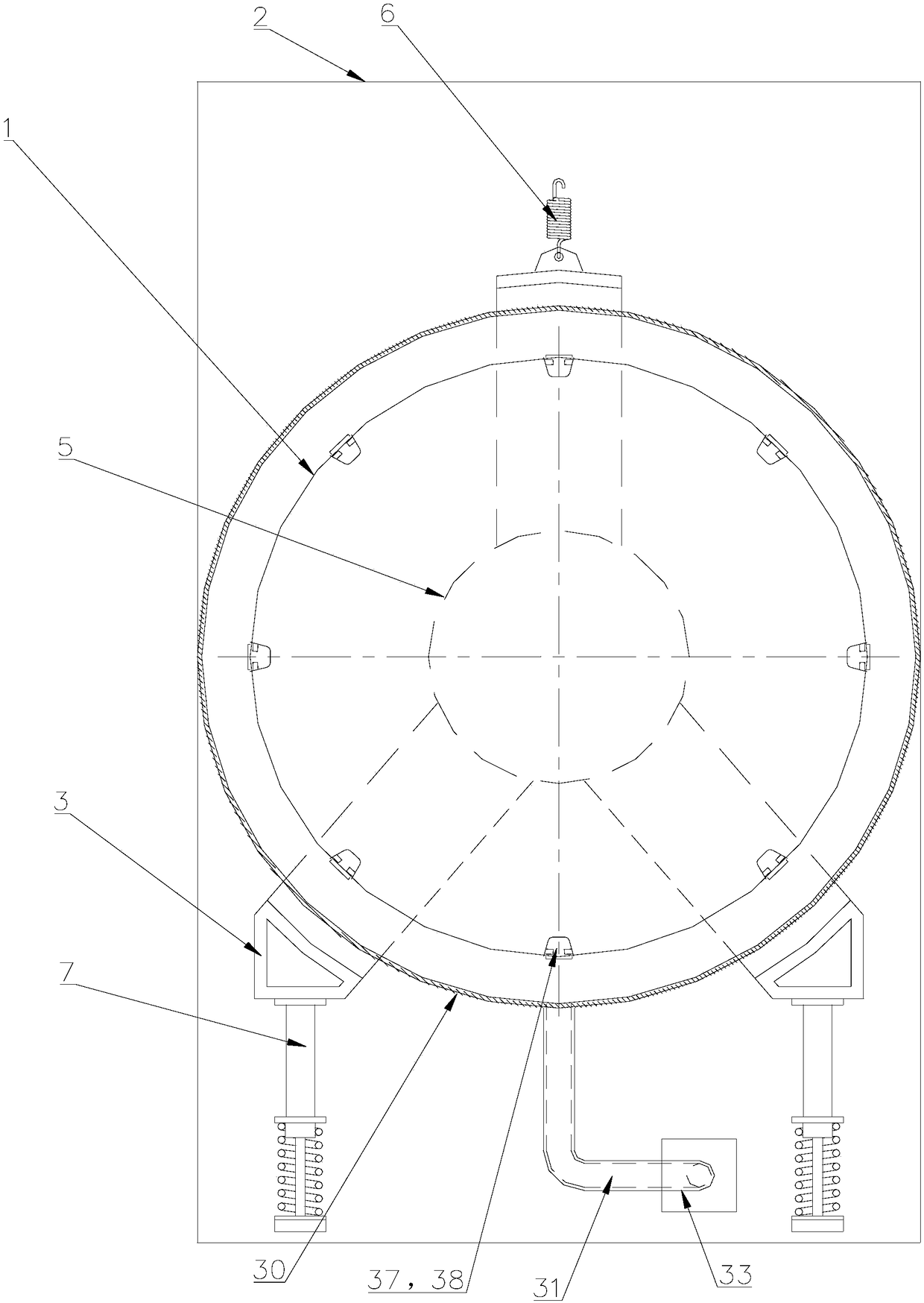

[0047] Such as figure 1 As shown, a washing machine is introduced in this embodiment. A door cover 4 is installed on the washing machine housing 2. A sealing ring 18 protruding from the outer periphery is provided on the inner side of the door cover 4. The sealing ring 18 is connected to the mouth of the inner cylinder. 101 is connected with an elastic seal so that when the door cover 4 is fastened to the mouth of the inner cylinder 101, the opening of the mouth of the inner cylinder is sealed to achieve the purpose of sealing the inner cylinder.

[0048] In this embodiment, the door cover 4 is arranged coaxially with the inner cylinder 1, the inner side of the door cover 4 is provided with a protruding part 22 protruding into the inner cylinder mouth 101, and the outer periphery of the protruding part 22 is provided with a radially outwardly protruding The sealing ring 18 is made of elastic material, and the sealing ring 18 is in sealing contact with the inner surface of the ...

Embodiment 2

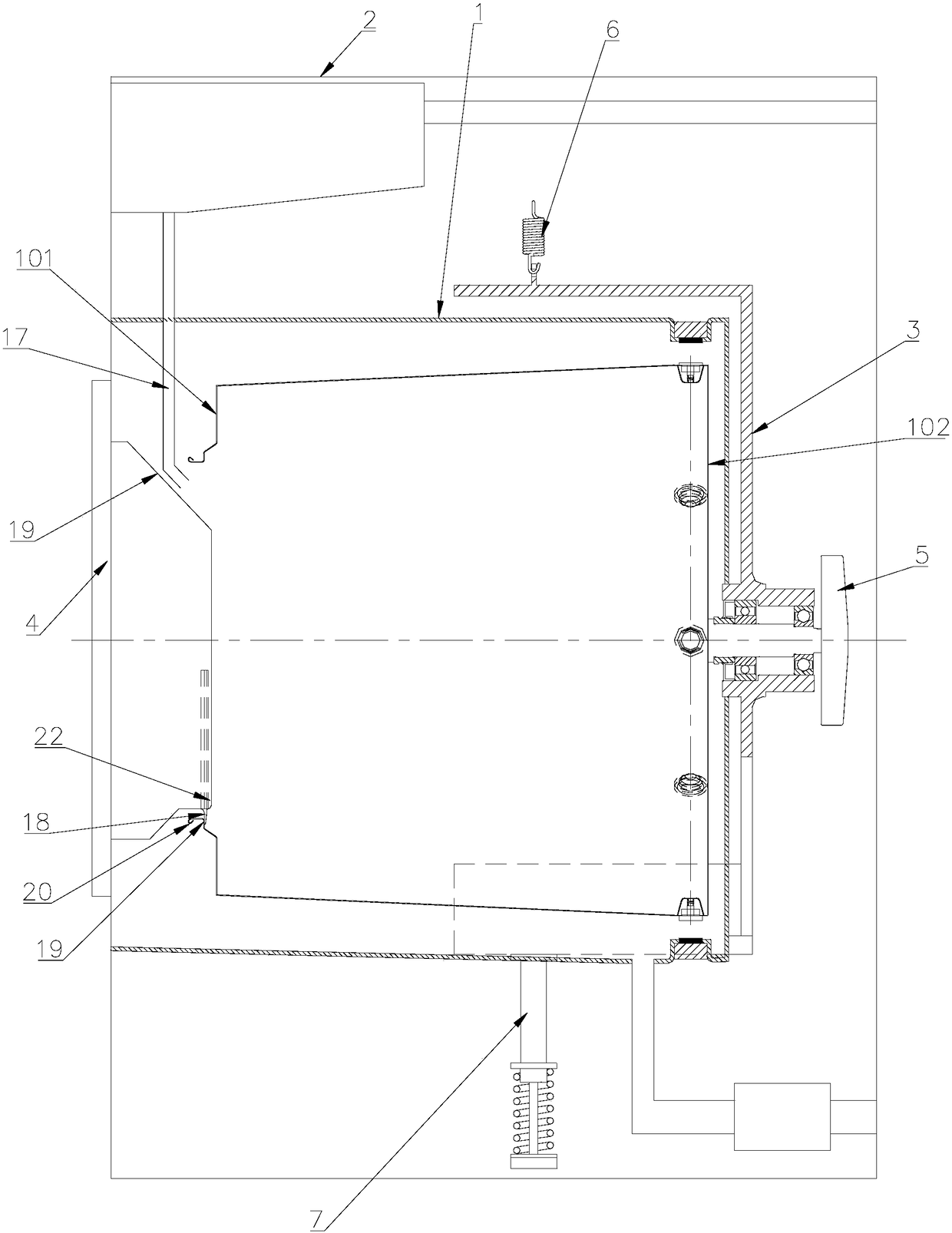

[0057] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the sealing ring 18 is a section of arc-shaped sealing ring 18 protruding radially outward from the outer periphery of the door cover 4, and the arc-shaped sealing ring 18 is arranged on the horizontal central axis At least the lower part of the inner cylinder mouth 101 is sealed after the door cover 4 is closed.

[0058] Since the water inflow of the drum washing machine is only to soak the clothes during the washing process, the water intake of the drum washing machine is generally less, and there will be no situation where the water inlet level exceeds the middle of the inner cylinder; therefore, in this embodiment, only in the The lower part of the door cover 4 is provided with a sealing ring 18, so that the lower part of the inner cylinder containing the washing water is sealed, and the purpose of sealing the mouth of the inner cylinder and preventing the water from flowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com