Adsorption type plunger latch

A technology of adsorption and latch, which is applied in the direction of building fastening devices, wing leaf fastening devices, buildings, etc., and can solve problems such as difficult adaptation of latches and damage to fixing parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

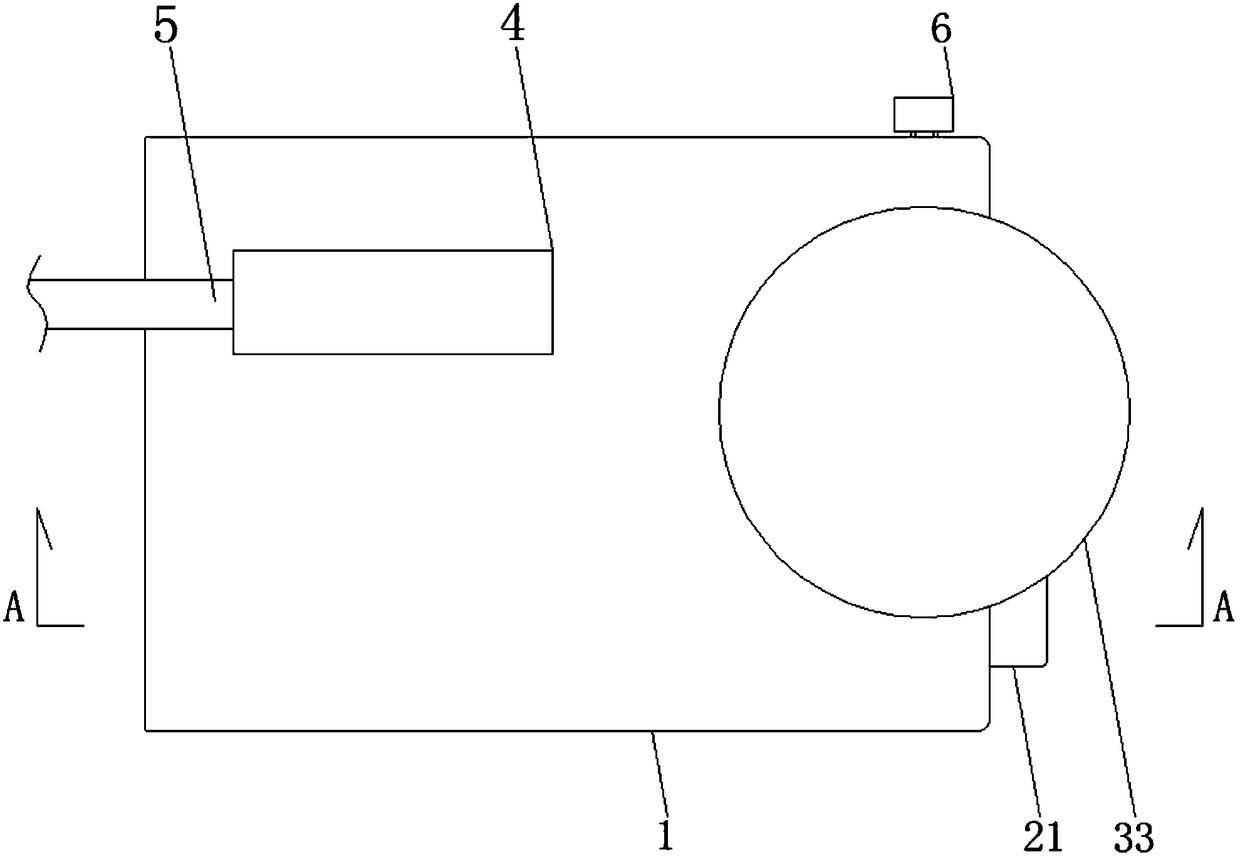

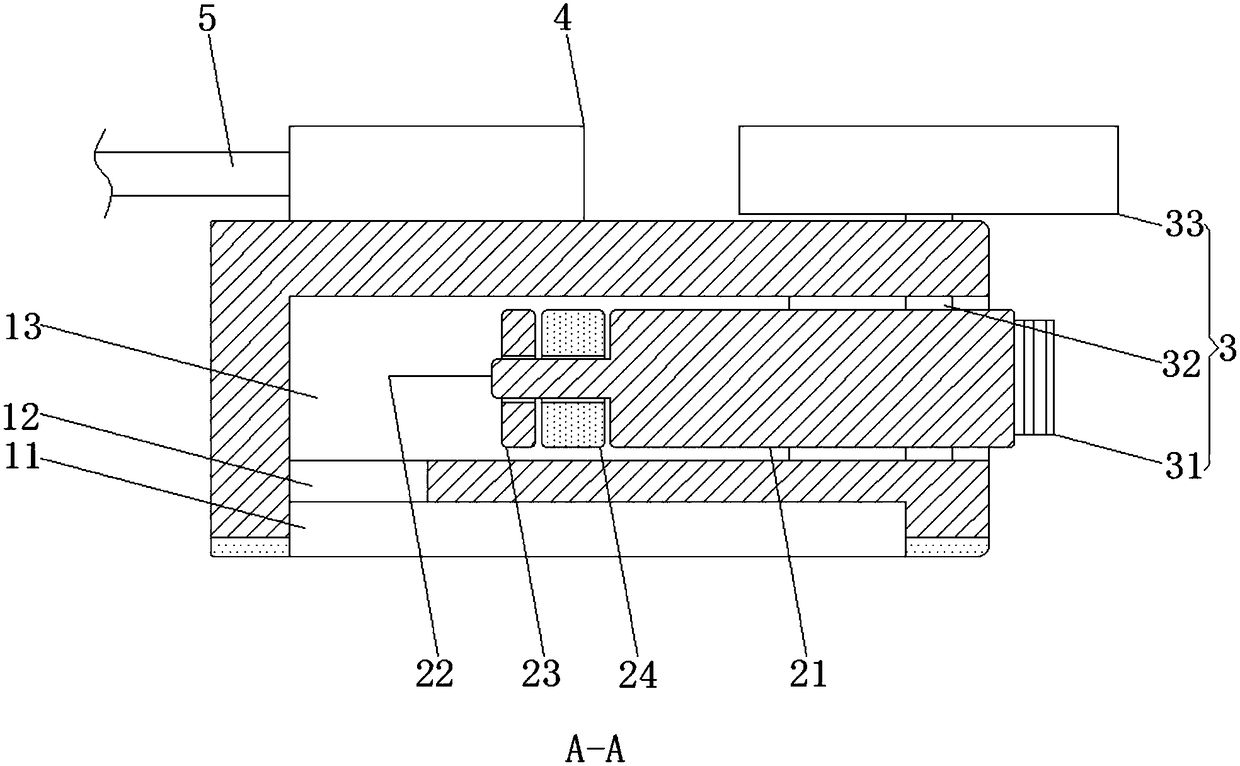

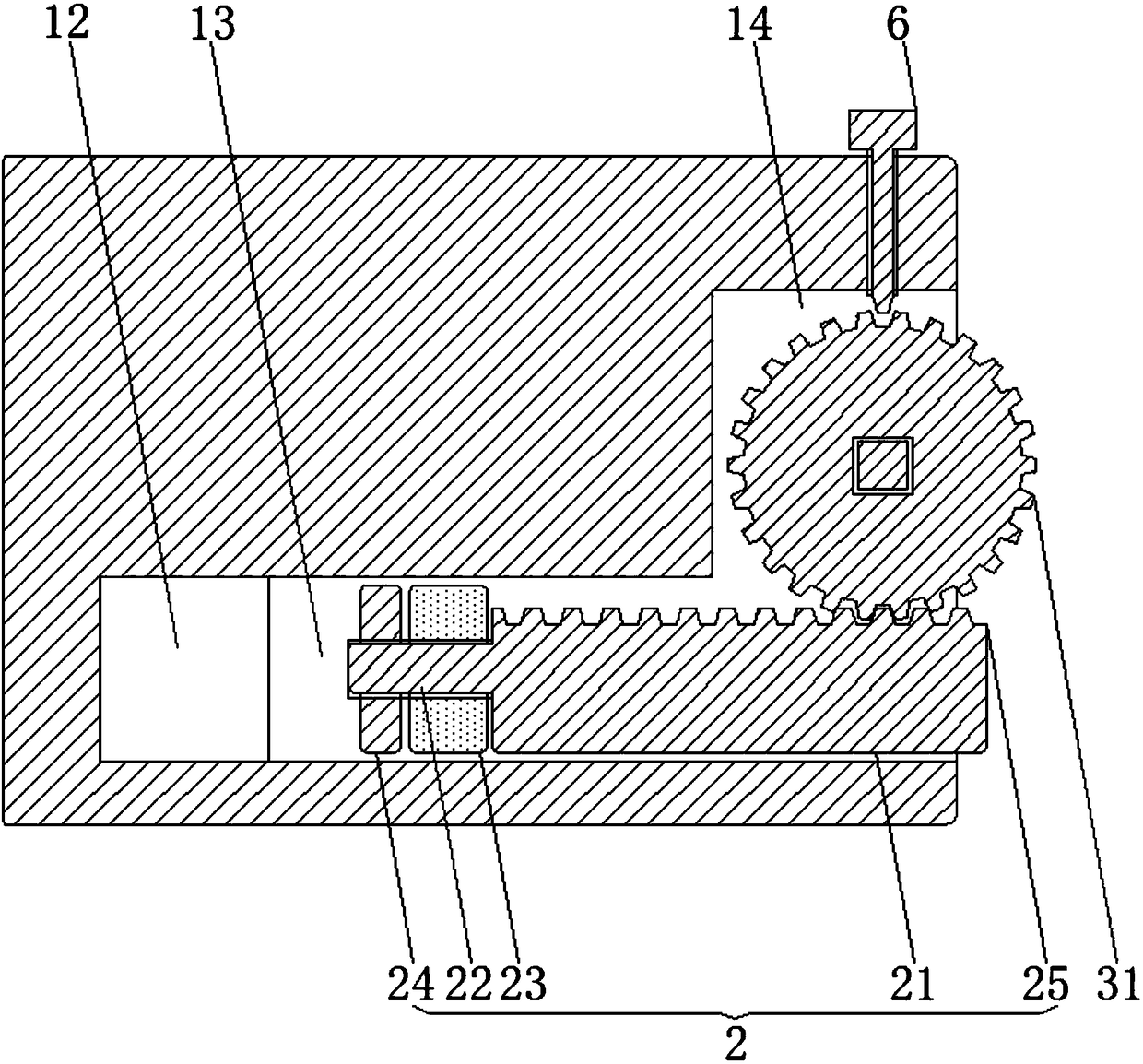

[0036] An adsorption type latch, comprising an adsorption base 1, a negative pressure generating device 2, a pressure regulating device 3, a lug with holes 4, and a locking rod 5;

[0037] The adsorption base 1 is provided with a pair, the lower end surface of the adsorption base 1 is provided with an adsorption groove 11, the upper end of the adsorption groove 11 is provided with a connecting hole 12, and one side of the adsorption base 1 is also provided with the connecting hole 12. Connected negative pressure suction hole 13, one side of the negative pressure suction hole 13 is provided with a rotation hole 14;

[0038] The negative pressure generating device 2 includes a piston rod 21 inserted in the negative pressure suction hole 13, a screw rod 22 arranged at the inner end of the piston rod 21, an annular plug 23 sleeved on the screw rod 22, a screw rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com