Detection device for measuring contour of non-circular inner hole and detection method

A technology of detection device and detection method, which is applied to measurement devices, optical devices, instruments, etc., can solve problems such as low detection efficiency of non-circular inner holes, and achieve the effect of avoiding measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

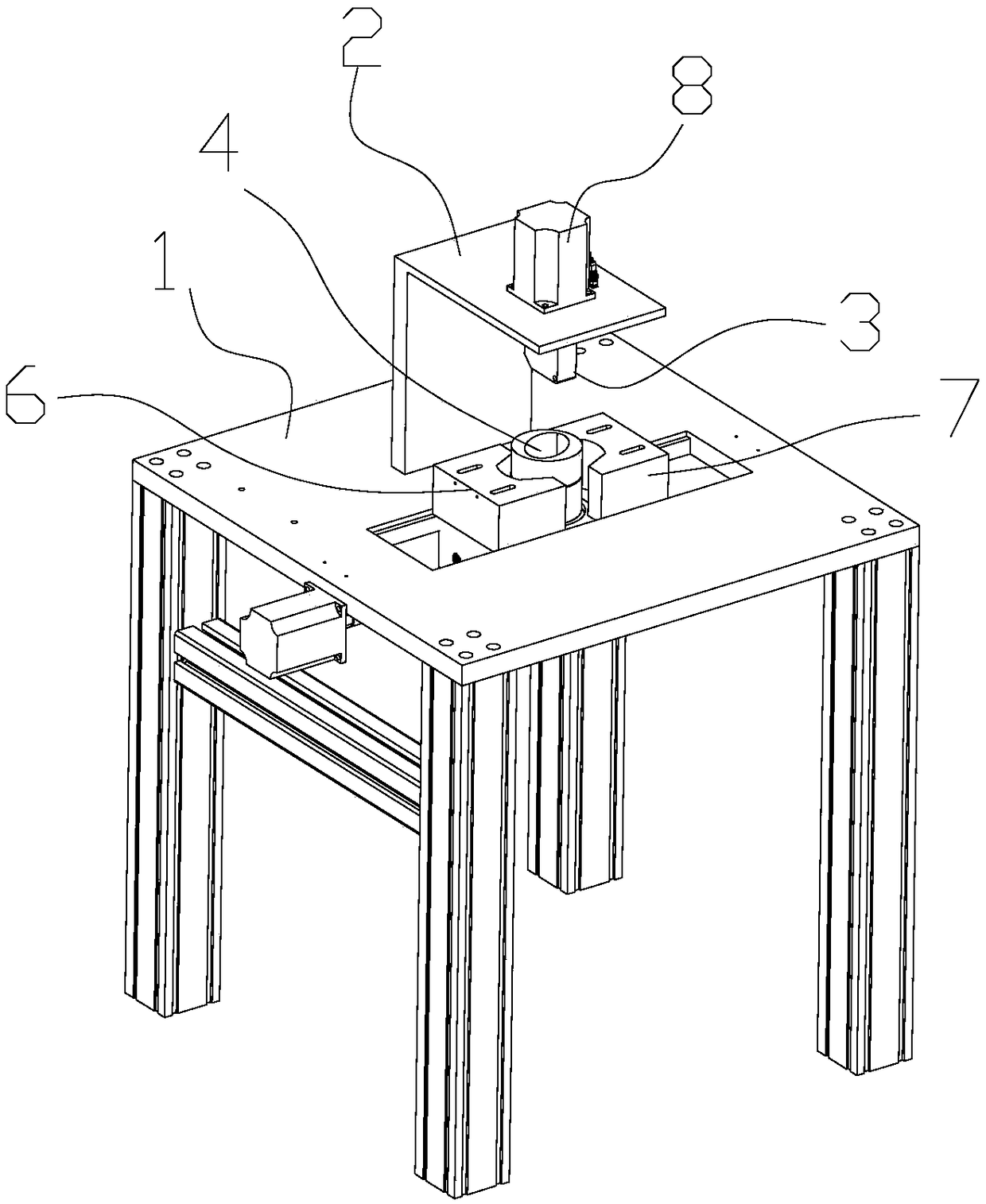

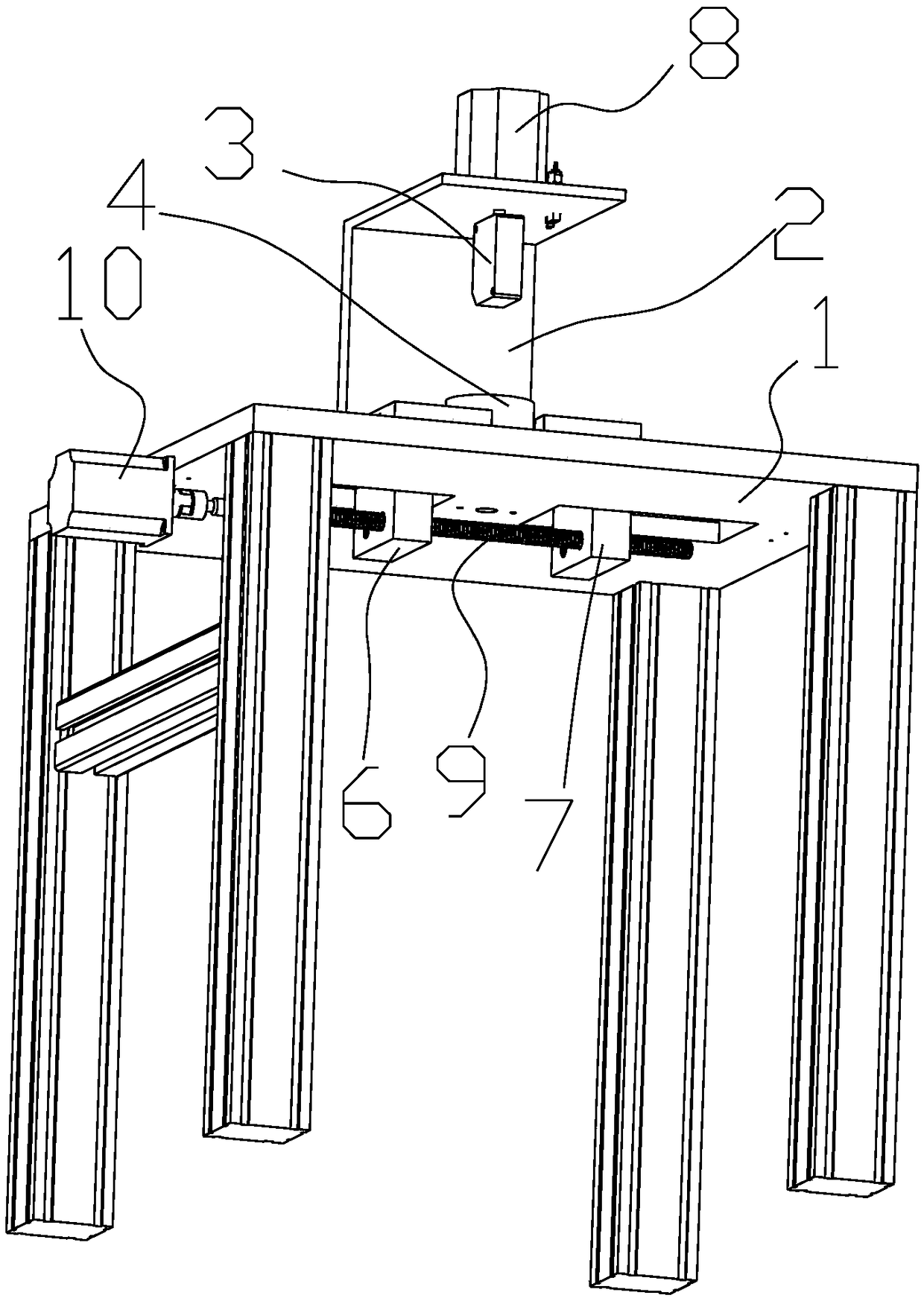

[0024] Such as Figure 1-2 , the first stepper motor 8 is fixed on the support frame 2, the laser displacement sensor 3 is fixed on the output end of the first stepper motor 8, the platform 5 is fixedly connected with the workbench 1, and the driving device includes the first V-shaped The positioning block 6 and the second V-shaped positioning block 7 are screwed to the first leading screw 9, and one end of the first leading screw 9 is connected with a second stepper motor 10, and the first V-shaped positioning block 6 and the second V-shaped positioning block The direction of rotation of the threads is opposite, and the working platform 5 is provided with a first position sensor for detecting whether the part 4 to be tested is at the mechanical zero point.

[0025] The detection method of the detection device of the present embodiment is:

[0026] (1) The second stepper motor 10 drives the first V-shaped positioning block 6 and the second V-shaped positioning block 7 to get ...

Embodiment 2

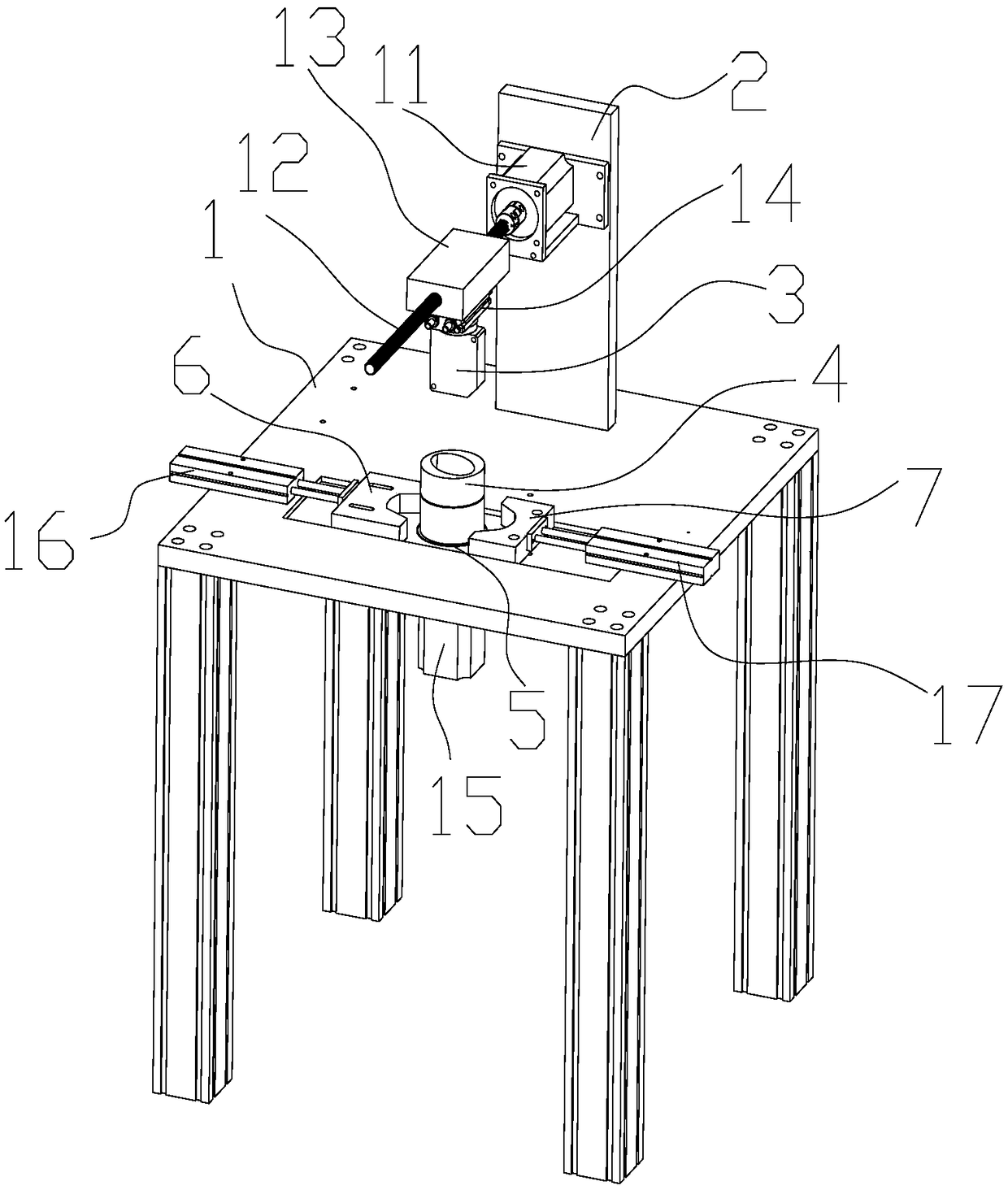

[0030] Such as image 3 , the support frame 2 is fixed with a horizontal linear module, the horizontal linear module includes a third stepper motor 11, the output end of the third stepper motor 11 is connected with a second lead screw 12, and the second lead screw 12 is threaded with a Nut slider 13, the lower end of the nut slider 13 is fixed with a rotary cylinder 14, the laser displacement sensor 3 is fixed at the output end of the rotary cylinder 14, and the support frame 2 is provided with a second position sensor for detecting whether the laser displacement sensor 3 is located at the mechanical origin , the platform 5 is connected with the workbench 1 in rotation, the fourth stepper motor 15 driving its rotation is connected below the platform 5, the first positioning and clamping cylinder 16 is connected on the first V-shaped block, and the second V-shaped block is connected with a The second positioning clamps the cylinder 17.

[0031] The detection method of the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com