Wire clamp device automatic to fasten

A fastening and wire clip technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve problems such as loss of life and major electric shock risks, and achieve the effect of ensuring normal working conditions, solving dangerous situations, and avoiding high-altitude inspection operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

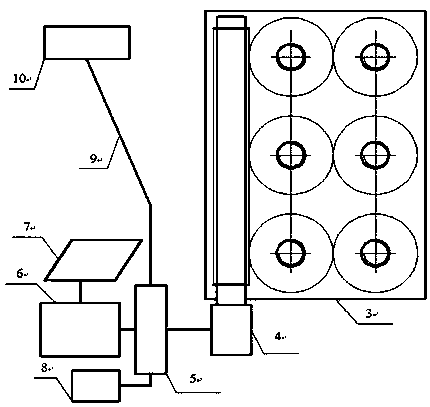

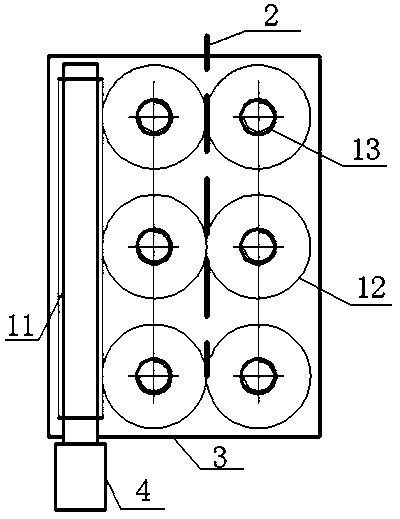

[0027] Embodiment 1: as Figure 1~3 As shown, the automatic fastening clamp device includes a clamp 1, a temperature sensor 2, a fastening part 3, a motor 4, a control switch 5, a storage battery 6, a solar photovoltaic panel 7, a lighting lamp 8, a transmission cable 9, Remote central control room 10;

[0028] The clamp 1 is an ordinary clamp provided with 3 U-shaped bolts, the fastening part 3 includes a worm 11 and 6 fastening gears 12, and the centers of the 6 fastening gears 12 are respectively provided with internal threads 13. Each U-bolt of the clamp 1 is matched with the internal thread 13 at the center of two fastening gears 12, and the two fastening gears 12 on the same U-bolt are engaged, and the worm 11 respectively meshes with one of the fastening gears 12 on each U-bolt, the temperature sensor 2 is installed on the fixed part of the high-voltage wire, and the temperature sensor 2 is connected to the control switch 5 through the wire, the output of the motor 4 ...

Embodiment 2

[0035] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, the difference is that the selected clamp 1 has 4 U-shaped bolts, and the number of fastening gears 12 is 8.

Embodiment 3

[0036] Embodiment 3: The structure of this embodiment is the same as that of Embodiment 1, the difference is that the selected clamp 1 has 5 U-shaped bolts, and the number of fastening gears 12 is 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com