Method for digesting vanadium-chromium-titanium alloy and detection method for digestion solution

The technology of a vanadium-chromium-titanium alloy and a detection method is applied in the field of detection and analysis, and can solve the problems that the simultaneous determination of secondary alloy elements cannot be satisfied, the complete digestion of vanadium-chromium-titanium is difficult to ensure, and the structure of the digestion alloy is complex, so as to improve product detection efficiency, The effect of reducing the influence of the matrix effect and shortening the inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

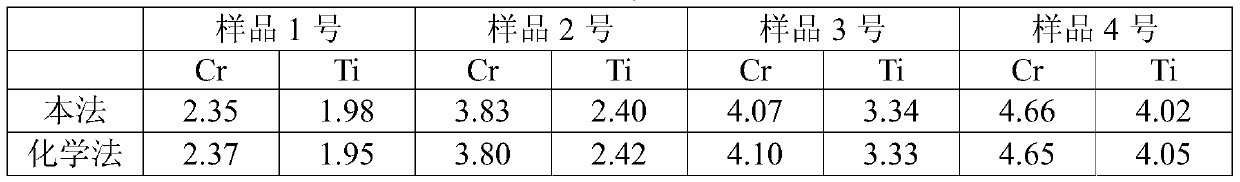

Embodiment 1

[0025] Sample detection solution digestion preparation of vanadium-chromium-titanium alloy

[0026] Weigh 0.2 vanadium-chromium-titanium alloy sample (No. 1 sample), add 30mL digestion reagent, place on a hot plate and heat to boil until the sample particles are dissolved and only a small amount of residue remains and the solution produces uniform large bubbles (the first digestion step); And keep the solution temperature at 65-75°C, add 0.5mL hydrofluoric acid to completely digest the sample residue, cool the solution to room temperature, dilute it with water and mix it evenly in a 100mL volumetric flask for testing (the second digestion step).

[0027] Determination of Minor Alloy Elements and Trace Impurity Elements in Sample Detection Solution by ICP-OES

[0028] Using Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-OES) as a detection method, the prepared vanadium chromium titanium sample detection solution is directly introduced into the ICP-OES instrument, ...

Embodiment 2

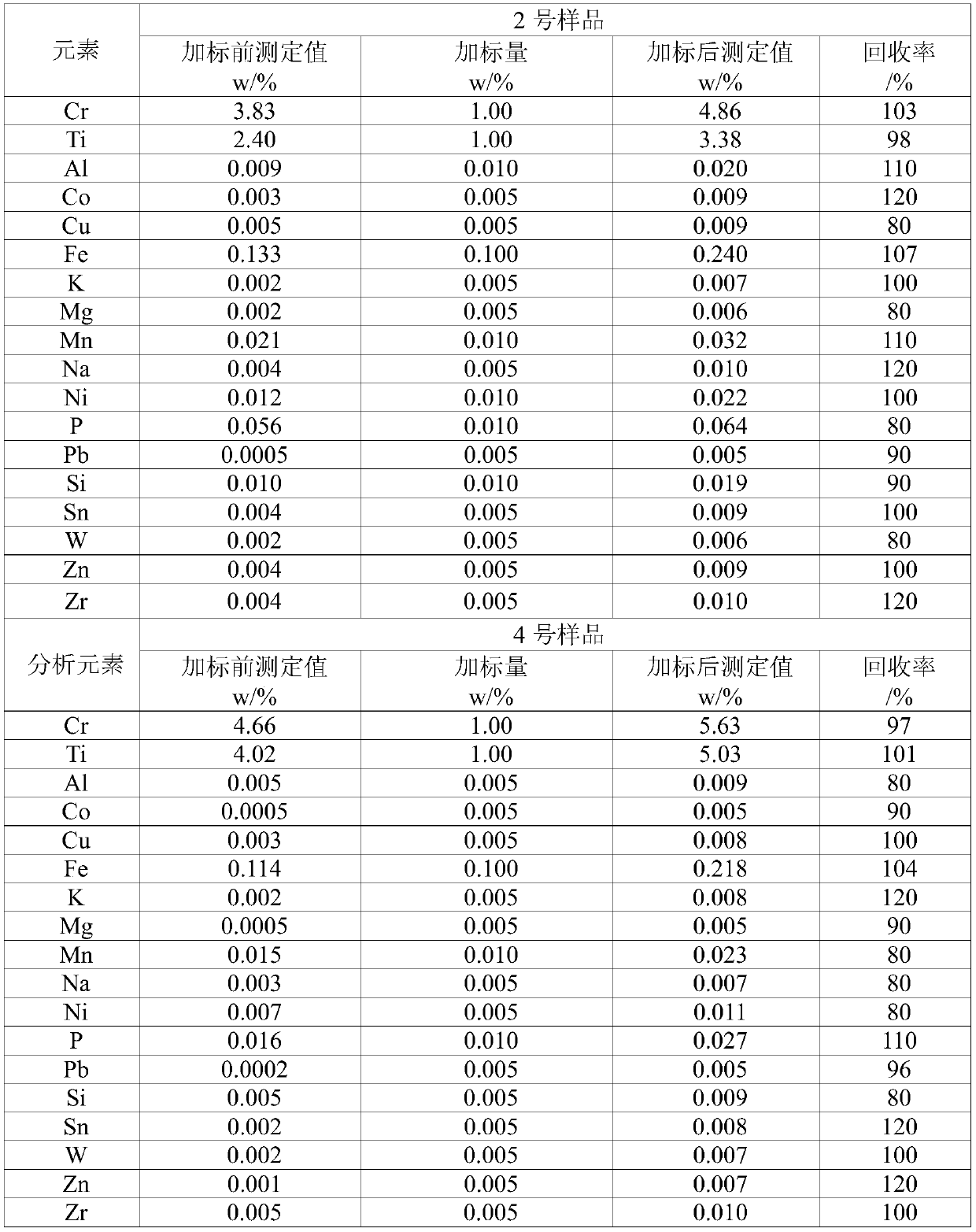

[0032] Weigh 0.3 vanadium-chromium-titanium alloy sample (No. 2 sample), add 45mL sample combination digestion reagent in proportion to carry out the digestion reaction of the first step, then add 0.8mL hydrofluoric acid to carry out the digestion reaction of the second step, in addition, The vanadium-chromium-titanium sample solution was prepared in the same manner as in Example 1, and the contents of minor alloying elements and trace impurities in the solution were determined by ICP-OES.

Embodiment 3

[0034] Weigh 0.4 vanadium-chromium-titanium alloy sample (No. 3 sample), add 60mL sample combination digestion reagent in proportion to carry out the digestion reaction of the first step, then add 1.0mL hydrofluoric acid to carry out the digestion reaction of the second step, in addition, The vanadium chromium titanium sample solution was prepared according to the same method as in Example 1, and the contents of minor alloy elements and trace impurities in the solution were determined by ICP-OES.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com