One-way restraint breaking buckle mechanism

A one-way, electric motor technology, applied in the field of strand rope continuous buckle breaking, can solve the problems of impracticality, inability to insert the plug into the rope, and the position and shape of the gap are not fixed, so as to achieve the effect of improving reliability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

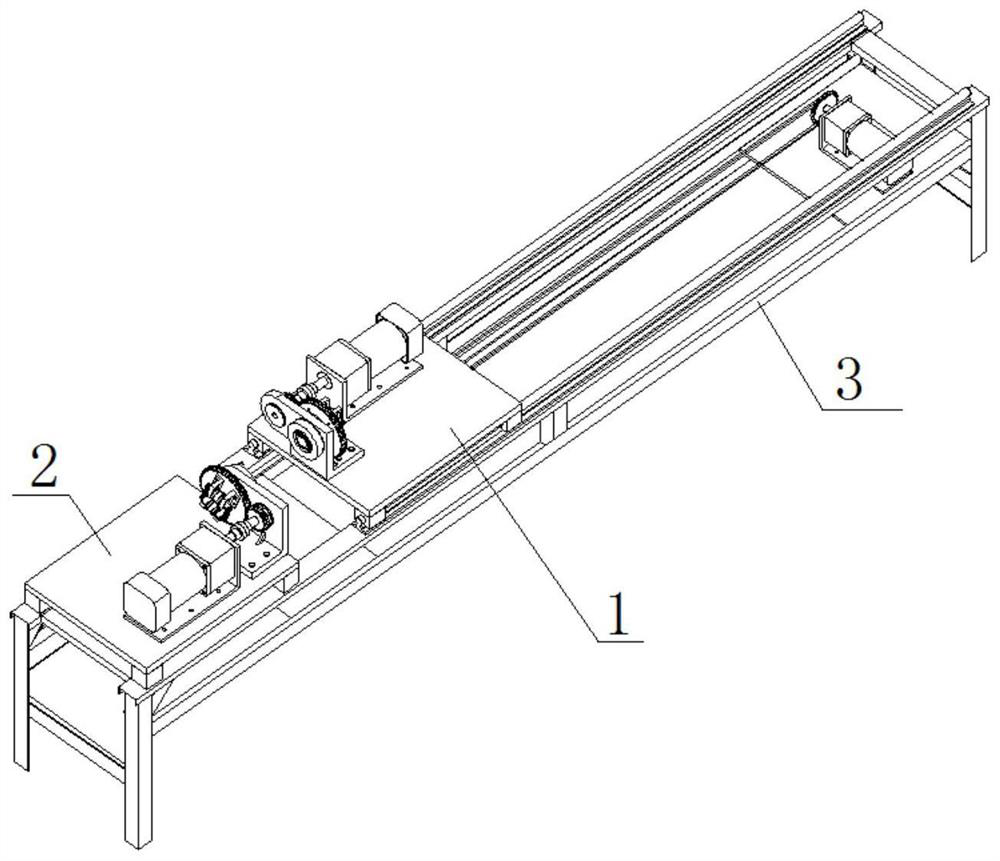

[0023] Such as figure 1 As shown, the one-way restraint breaking mechanism of the present invention includes a movable twisted rope part 1, a fixed twisted rope part 2 and a base 3, and the movable twisted rope part 1 and the fixed twisted rope part 2 are both arranged above the base 3, wherein The fixed twisted rope part 2 is fixedly connected with the base 3 , and the movable twisted rope part 1 can reciprocate along the top surface of the base 3 .

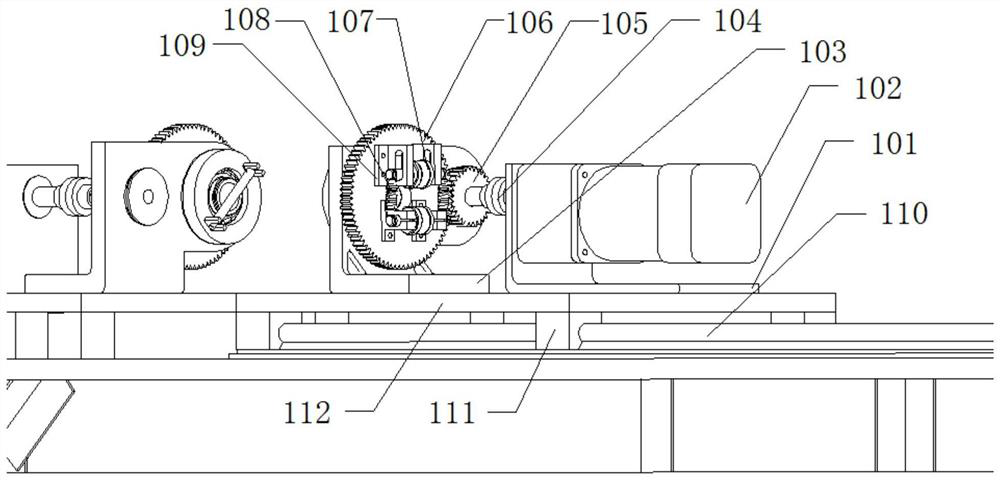

[0024] Such as figure 2 As shown, the active twisting rope part 1 includes a clamping and rotating device and a reciprocating moving device, wherein the clamping and rotating device includes a motor I102, a coupling I104, a transmission pinion I105, a twisting rope gear I106, a clamping sheave I107, a clamping Spring I108, clamping guide rail I109 and support platform I112, motor I102 are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com