Method and device for controlling hot rolling process

A technology of process control and sizing machine, applied in rolling mill control device, length measuring device, metal rolling, etc., to achieve the effect of high judgment accuracy, production quality assurance, production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

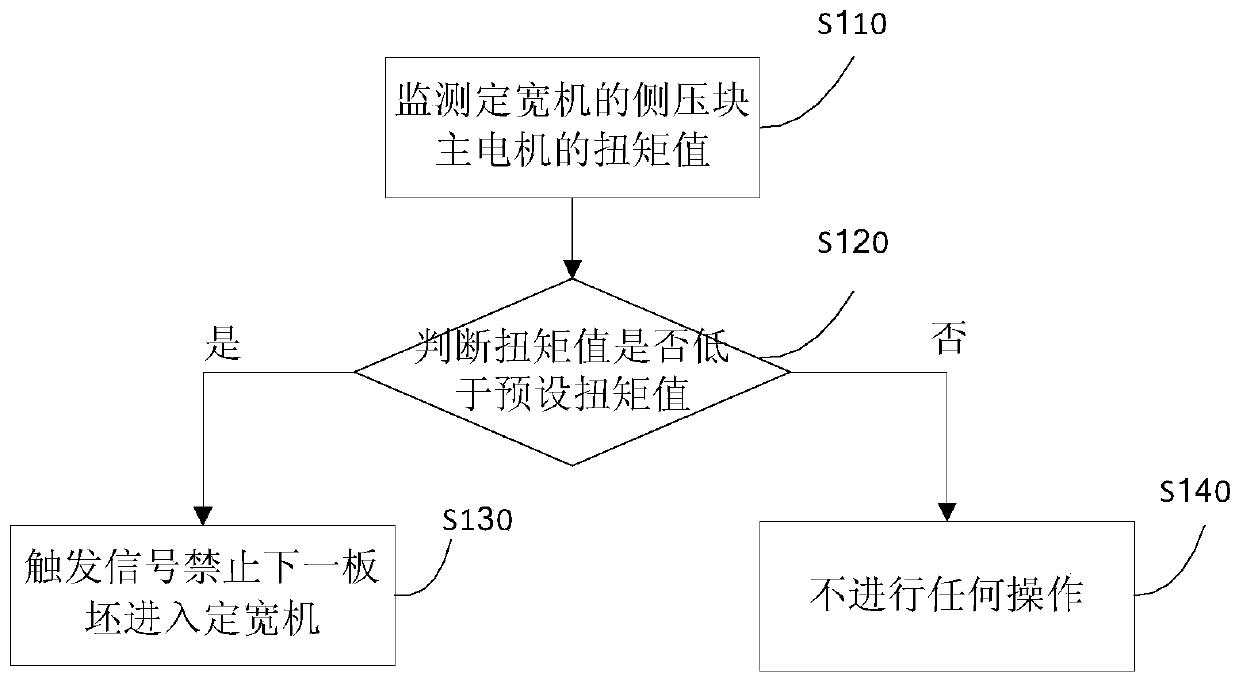

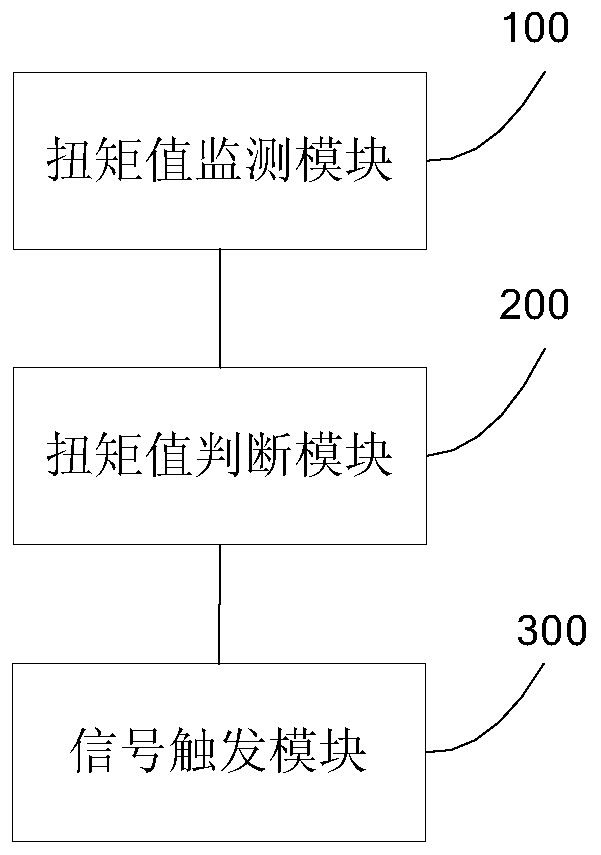

[0041] The embodiment of the present invention provides a hot rolling process control method and device, which solves the technical problem in the prior art that the operator fails to find the slab slipping in the area of the slab in time, and realizes the guarantee of production quality and production efficiency. technical effect.

[0042] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

[0043] By judging whether the monitored torque value of the main motor of the side pressing block of the sizing machine is lower than the preset torque value, it is judged whether the slab is slipping in the sizing machine, so that the trigger signal prohibits the next slab from entering the sizing machine, Therefore, a quick response is realized when the slab slips in the width-fixing machine, which not only ensures the production quality, but also ensures the production efficiency. The embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com