Dismantling device for charging screws on storage battery

A technology for dismantling devices and batteries, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the labor cost of battery packaging work, reducing the work efficiency of battery packaging work, etc., so as to reduce labor costs and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

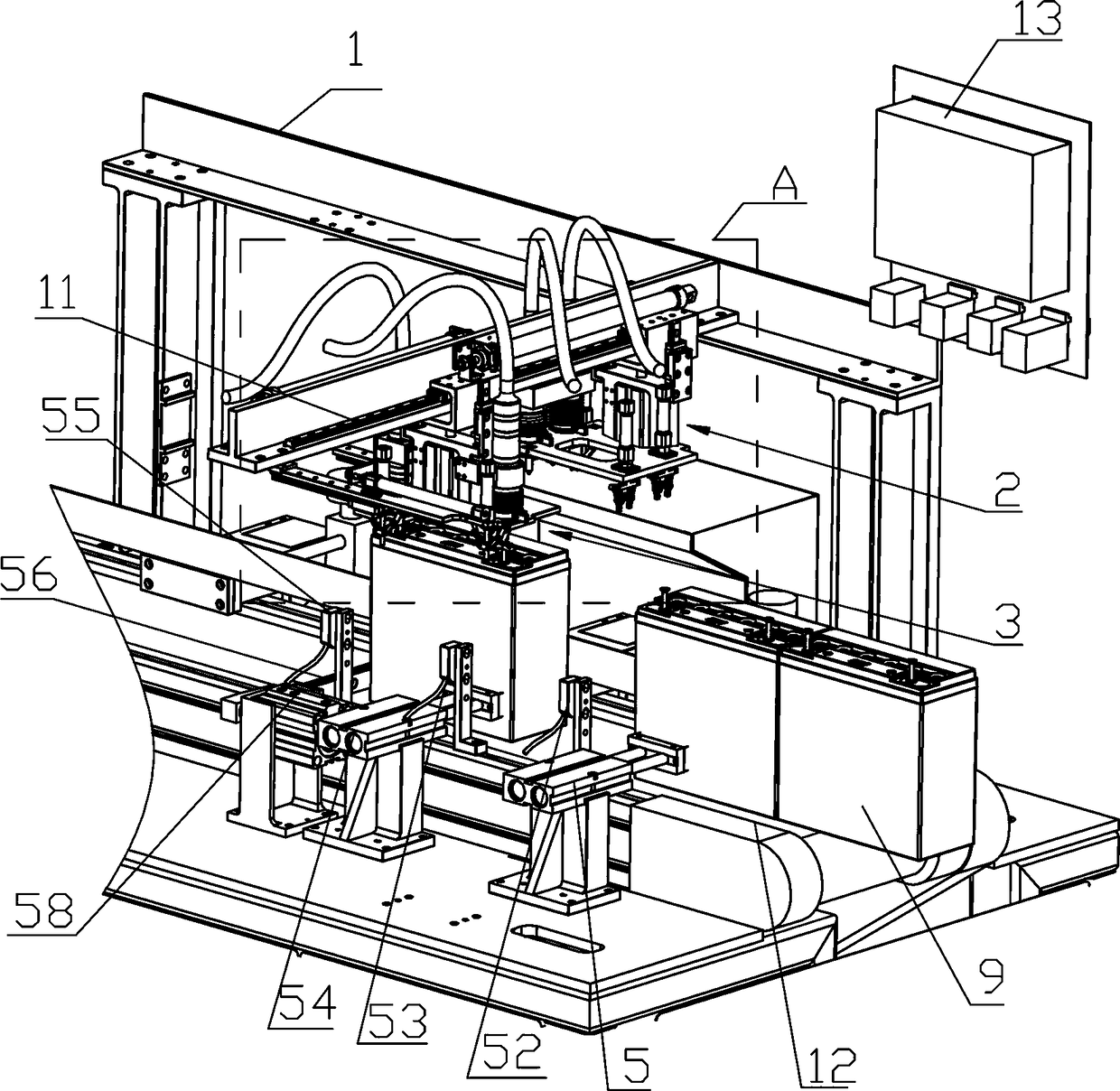

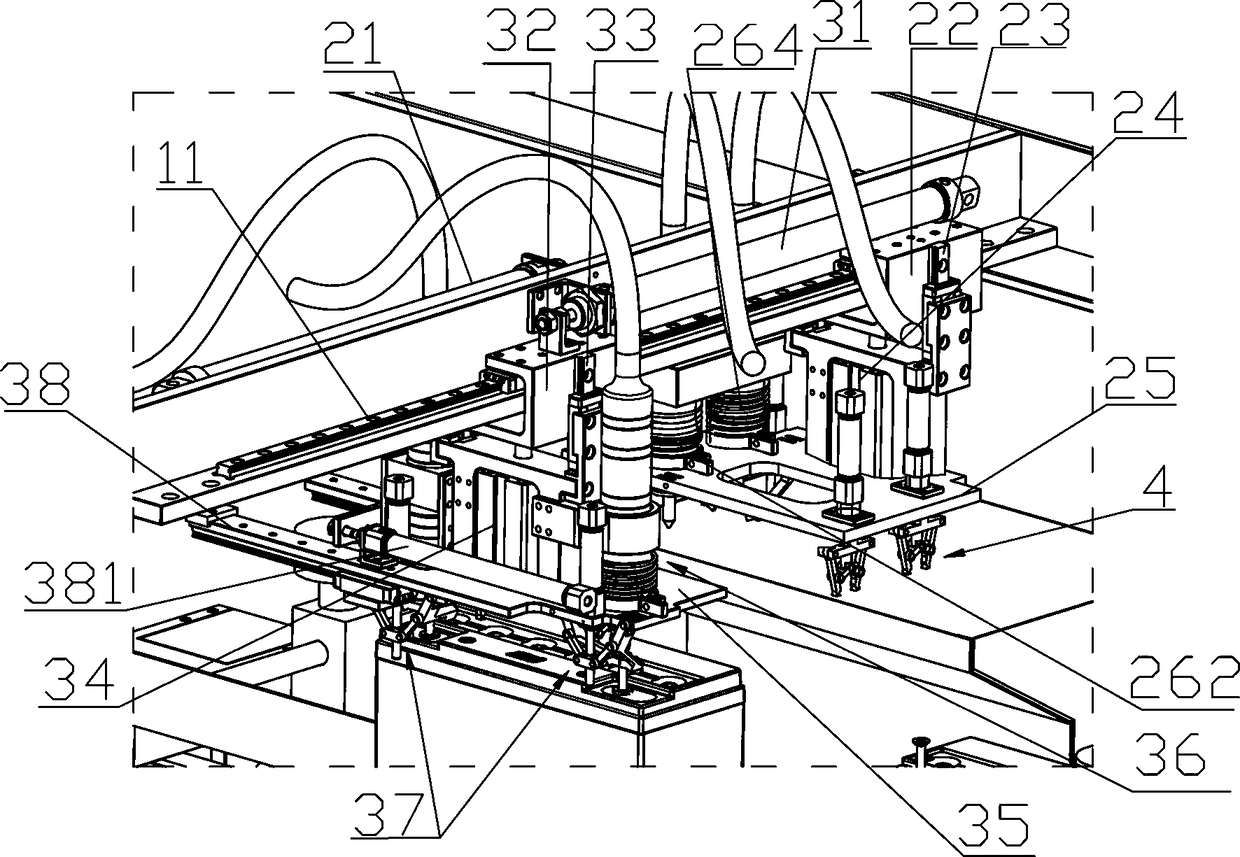

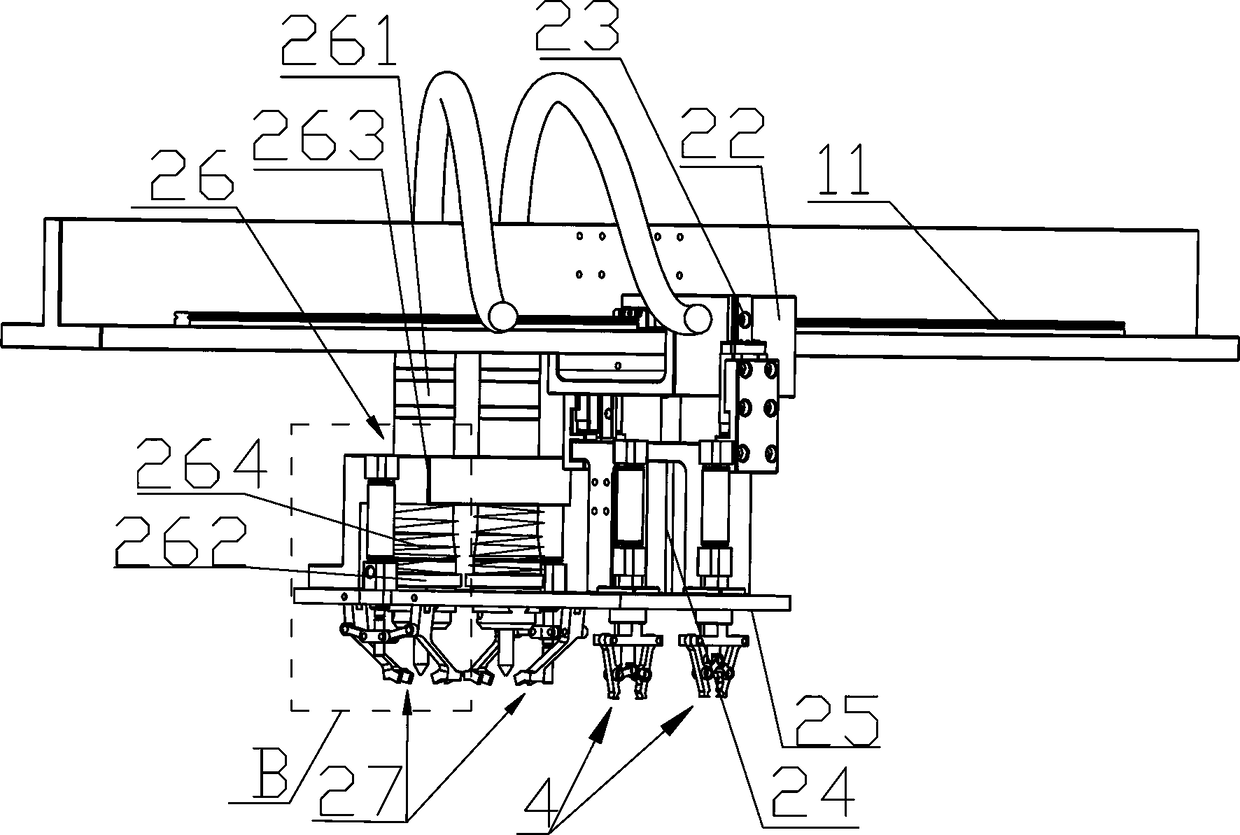

[0023] like figure 1 , figure 2 , Image 6 , Figure 7 As shown, the dismantling device for charging screws on the battery includes a frame 1, on which a conveyor belt 12 that can transport the battery 9 from the rear to the front is provided, and a straight line running left and right is arranged on the frame 1 above the conveyor belt 12 The rail 11 is slidably provided with two dismantling and grabbing devices capable of dismantling and grabbing the two charging screws on the batteries of different specifications, namely the first dismantling grabbing device 2 and the second dismantling grabbing device 2 Grabbing device 3, the two dismantling and grasping devices are respectively provided with left and right driving mechanisms on the frame 1 that can drive them to slide left and right on the linear track 11—that is, the first left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com