Multifunctional robotic gripper

An industrial robot and hand grasping technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of small grasping load, impact on work efficiency, and low positioning accuracy, so as to improve production efficiency, improve flexibility, and improve The effect of finger stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] An industrial robot end effector of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

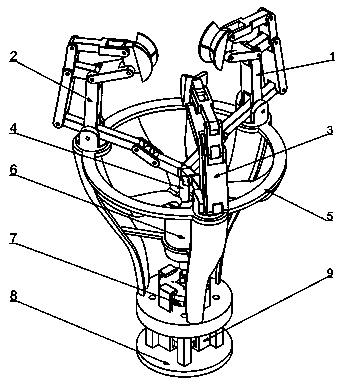

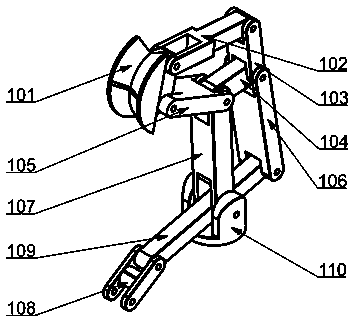

[0037] The invention relates to an end effector of an industrial robot, which adopts the design of a three-grab self-centering structure, and three hand grippers interact to form an end operation part. The connection between the hand clamp and the chassis is fixed by bolts. Whether the end effector can accurately clamp the product and deliver the product to the designated position depends not only on the positioning accuracy of the end effector, but also on the magnitude of the clamping error and the installation positioning accuracy. With the structural device of the present invention, according to the shape and size of the product and the requirements of the material, hardness and surface properties of the clamping part, the fingertip part is designed with a half-moon-shaped V-shaped groove surface and made of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com