Excitation tamping device

A technology of vibration excitation and tamping machine, applied in the field of rail transit, can solve the problems of unfavorable to ensure the centering and clamping, difficult to achieve dense clamping, poor force balance, etc., to achieve modular integrated connection, Force-balanced, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

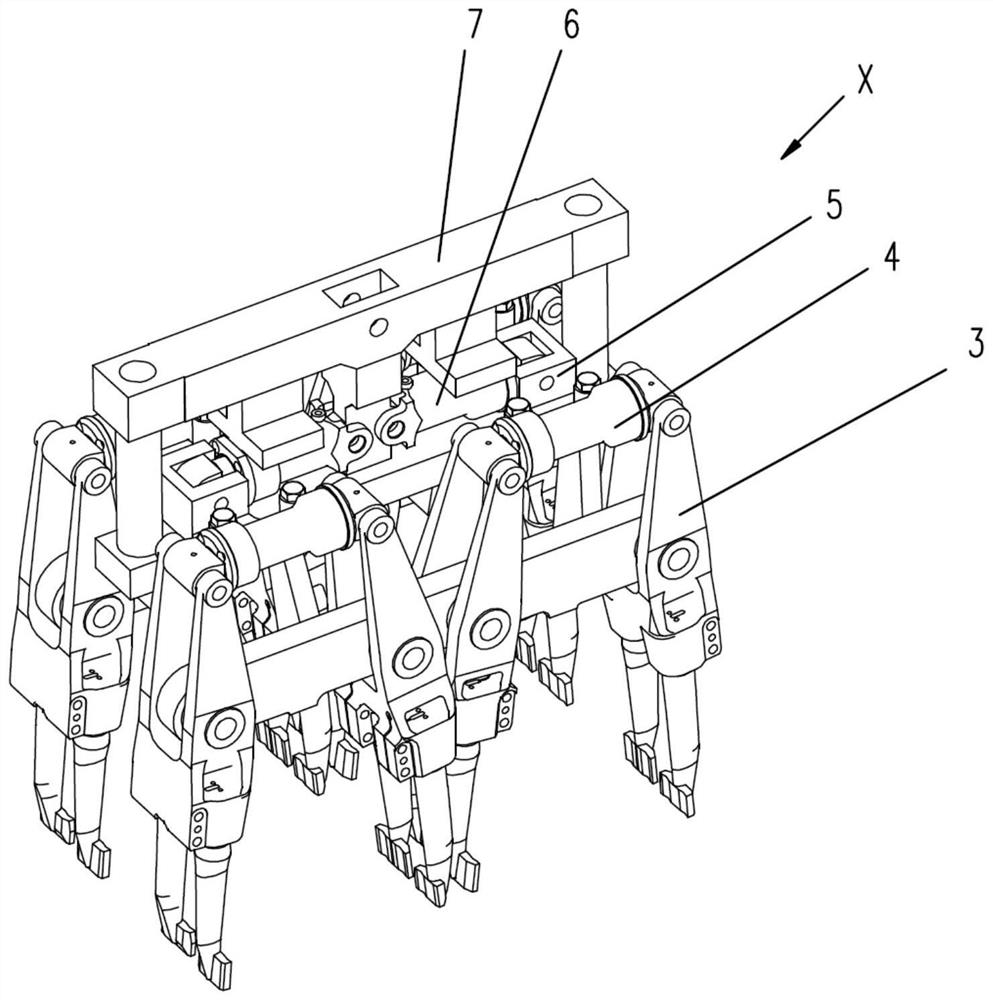

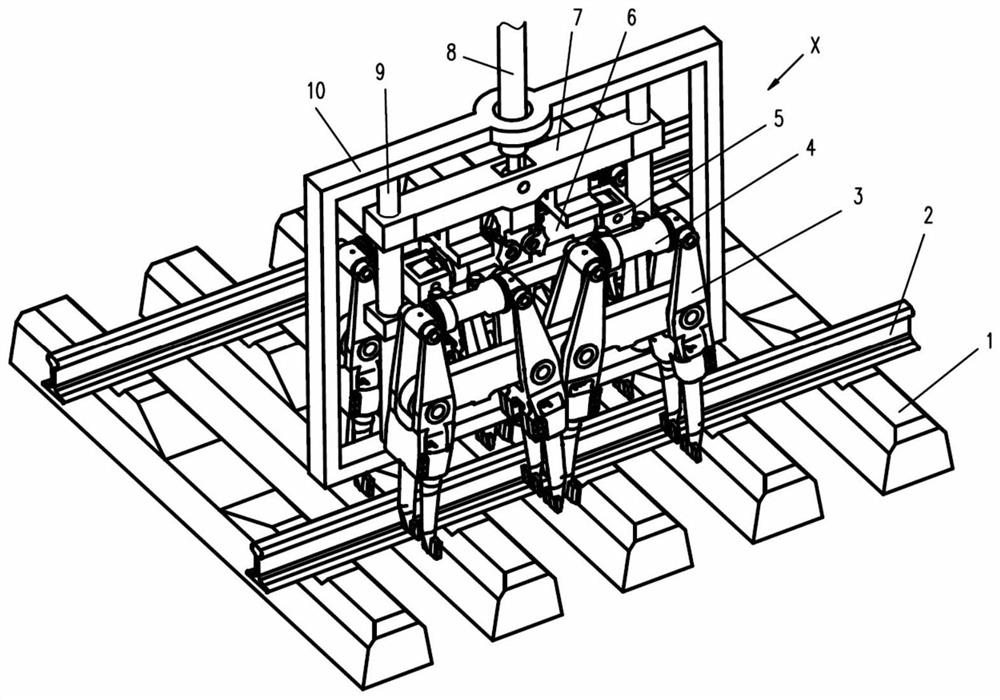

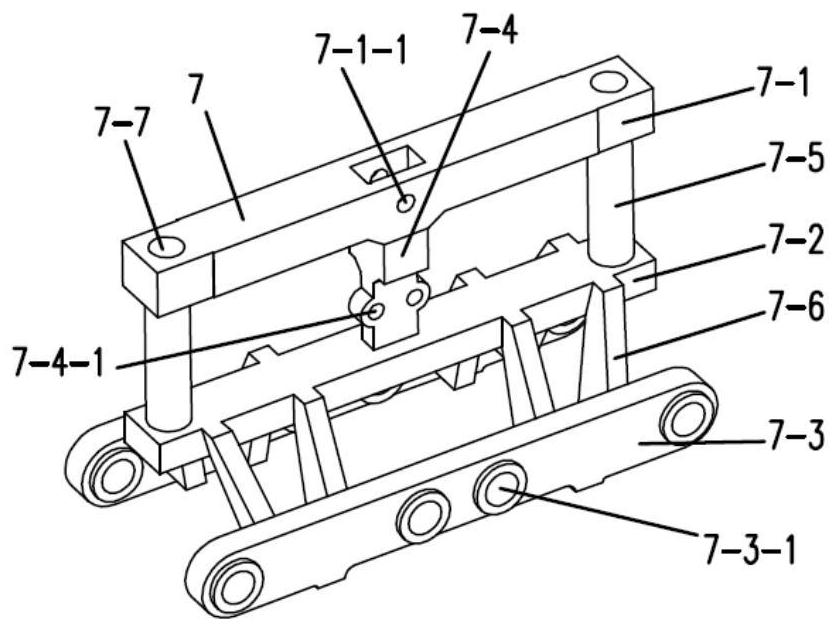

[0032] This embodiment is a double-pillow hydraulic excitation vibration tamping device, and its basic structure is as follows: figure 1 (see figure 2 ), the hydraulic vibration excitation tamping device X mainly consists of a liftable tamping frame 7, two hydraulic vibration cylinders 6 symmetrically hinged in the middle of the tamping frame 7, and two hydraulic vibration excitation cylinders 6 respectively. Two connecting plates 5 hinged at the piston rod ends of the oil cylinder 6, four double-ended telescopic clamping oil cylinders 4 fixedly connected to the two connecting plates respectively, are respectively hinged on both sides of the tamping frame 7, and the upper ends are respectively connected to the corresponding double ends. It is composed of four pairs of tamping arms hinged by end telescopic clamping cylinders. Driven by the lifting cylinder 8, the device can move up and down along the vertically arranged guide column 9 installed on the car body frame 10, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com