Compression mold with charging structure

The technology of a compression molding mold and a buckle structure is applied in the field of compression molding molds, which can solve the problems of large consumption of manpower and material resources, and achieve the effects of saving labor, saving time, and eliminating the step of reclaiming materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

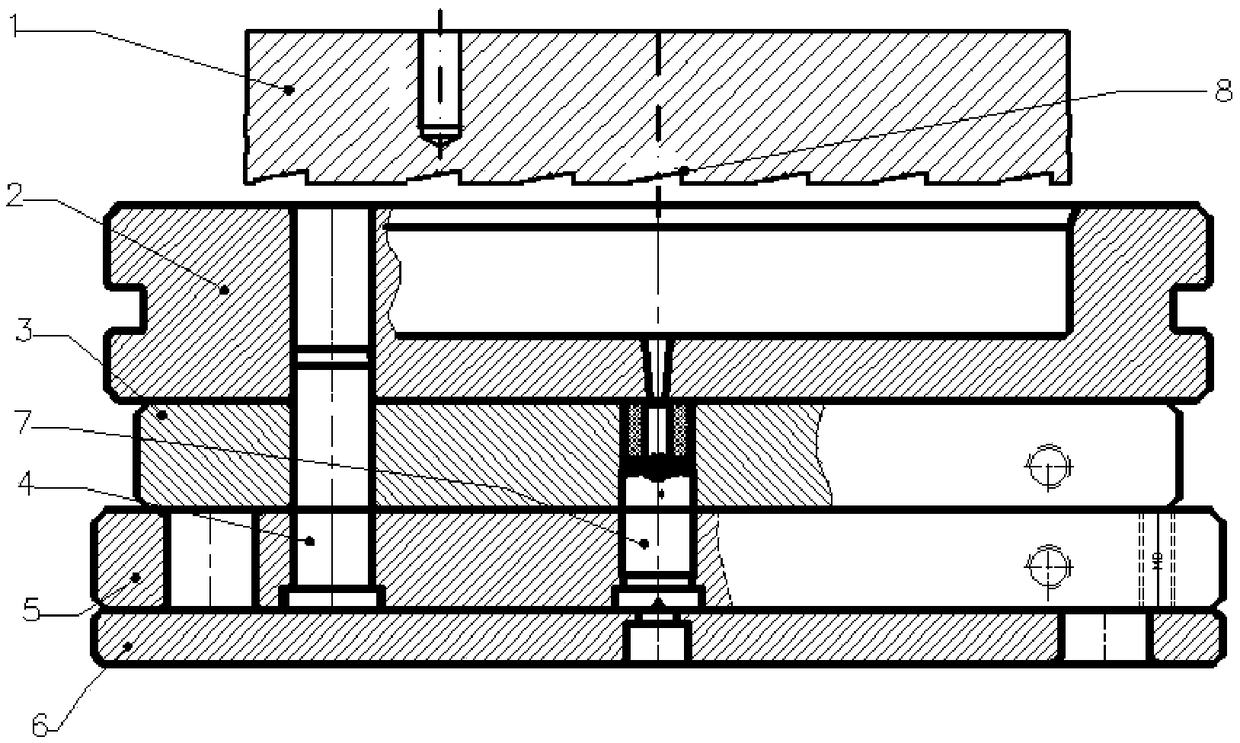

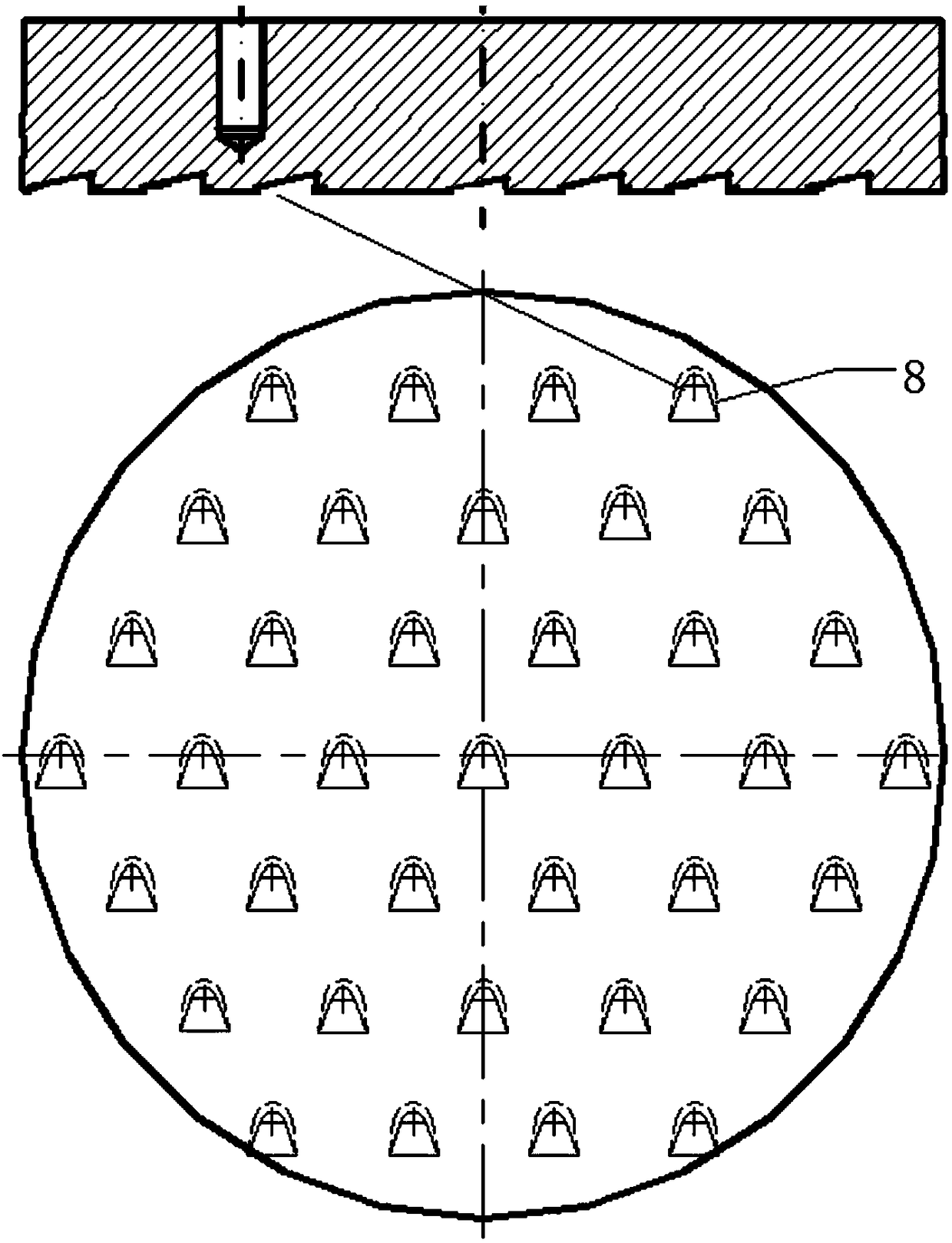

[0016] Such as Figure 1-2 Shown is a compression mold with an automatic feeding structure. The compression mold includes a lower template 5, a middle template 3, a material chamber 2, and a plunger 1 from bottom to top. The guide device 4 guides the lower template 5 , middle template 3, material chamber 2 positions; the bottom of the plunger 1 is provided with a belt structure, the belt structure 8 is a notch, and the vertical position of the top of the notch and the bottom are staggered; the bottom of the lower template 5 A backing plate 6 is provided; the guide device 4 is one of a guide plate, a conduit, and a guide post; the cross-section of the strip structure is obtuse-angled triangle, and the obtuse angle is arranged at the bottom.

[0017] When in use, put the preheated plastic into the material chamber 2, the plastic is heated and plasticized into a melt, the plunger 1 descends, presses down on the melt, and the melt squeezes into the mold of the middle template 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com