Lifting appliance for production

A technology of a spreader and a fixed seat, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of difficulty in ensuring the closure of the spreader, wire rope breakage, dangerous accidents, etc., saving process time, reducing labor intensity, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

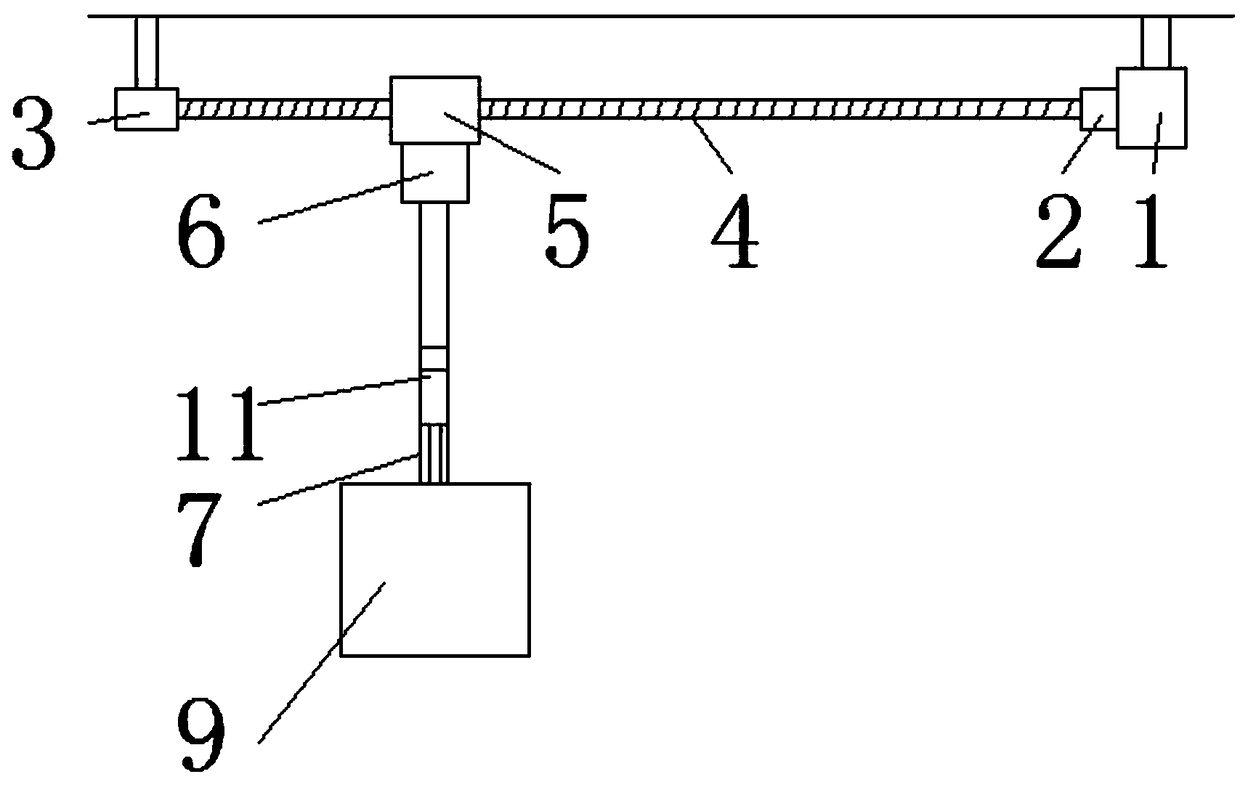

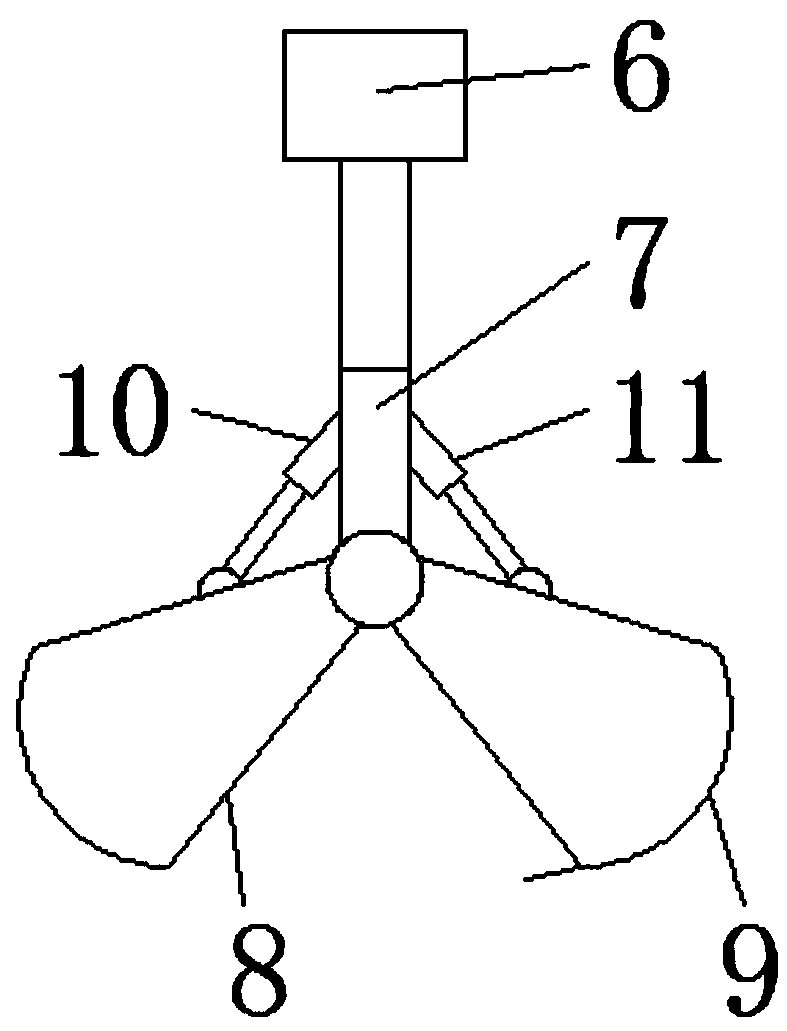

[0014] The preferred implementation of the production hanger of the present invention will be described in detail below in conjunction with the accompanying drawings.

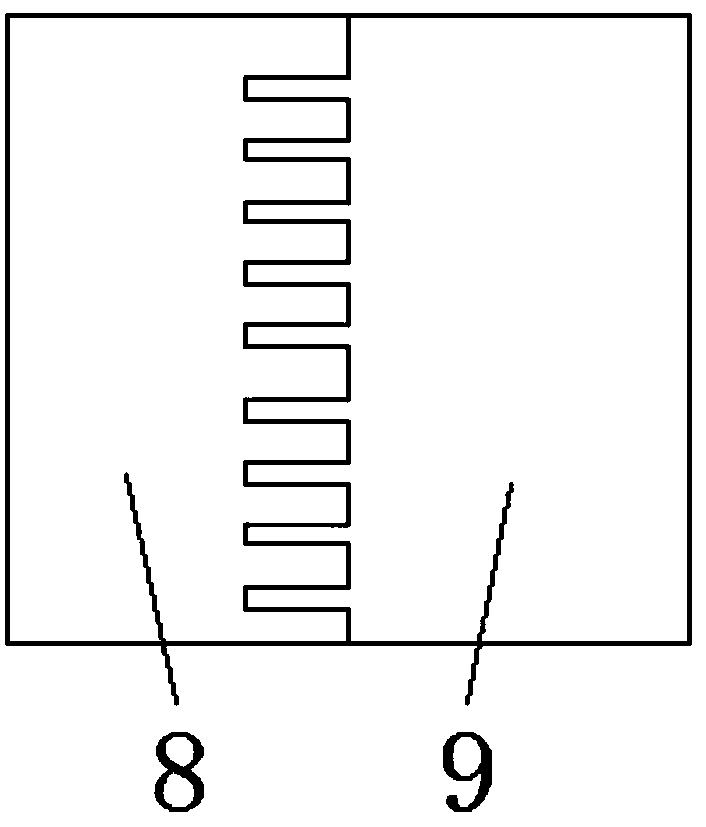

[0015] Figure 1-Figure 3 Show the specific implementation of the production sling of the present invention: a production sling, including a fixed seat 1, the fixed seat 1 is provided with a motor 2, the main shaft of the motor 2 is connected with a lead screw 4 through a coupling , the other end of the lead screw 4 is rotatably connected with a swivel seat 3, the lead screw 4 is also provided with a lead screw nut 5 threaded with the lead screw 4, and the lower end of the lead screw nut 5 is fixed with a hydraulic drive mechanism 6, so The end of the piston cylinder of the hydraulic drive mechanism 6 is connected with a bracket 7, and the bottom end of the bracket 7 is hinged with a symmetrically arranged left grab bucket 8 and a right grab bucket 9, and the left and right sides of the bracket 7 are also hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com