FRP-constrained basin-shaped rubber support

A technology of rubber bearings and pots, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of lack of effective restraint of rubber layers, fracture and damage of steel pots, and large lateral deformation, so as to improve rigidity, load capacity, and strength The effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

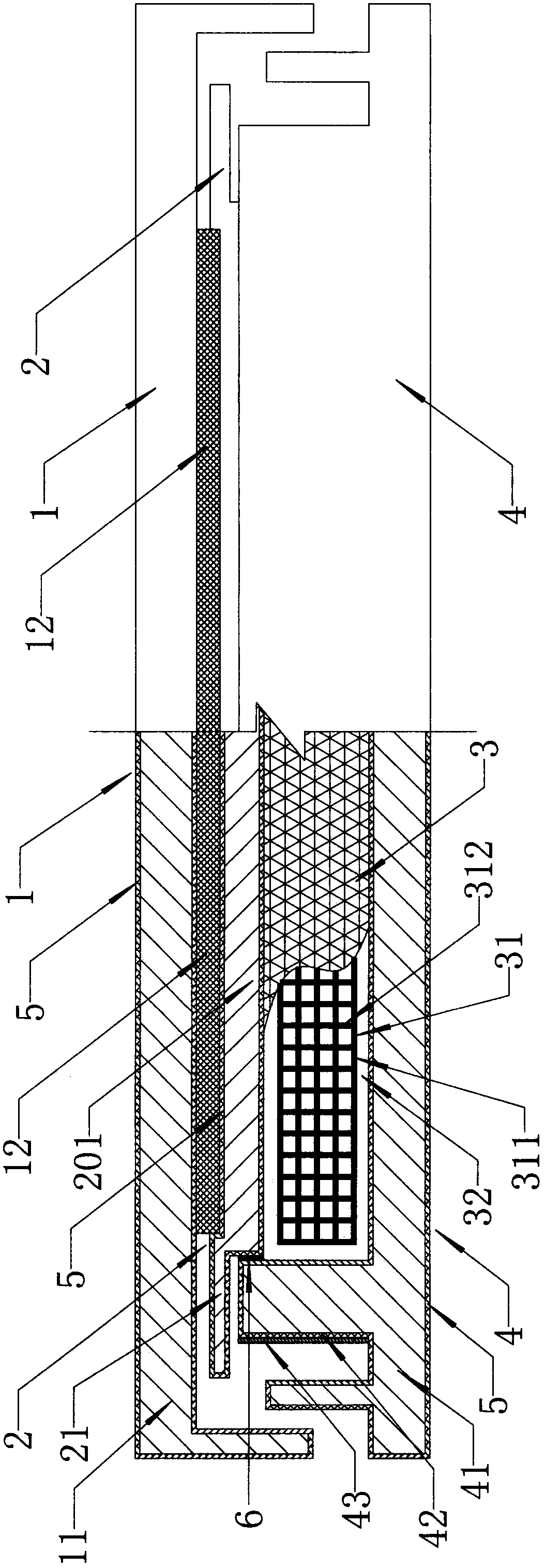

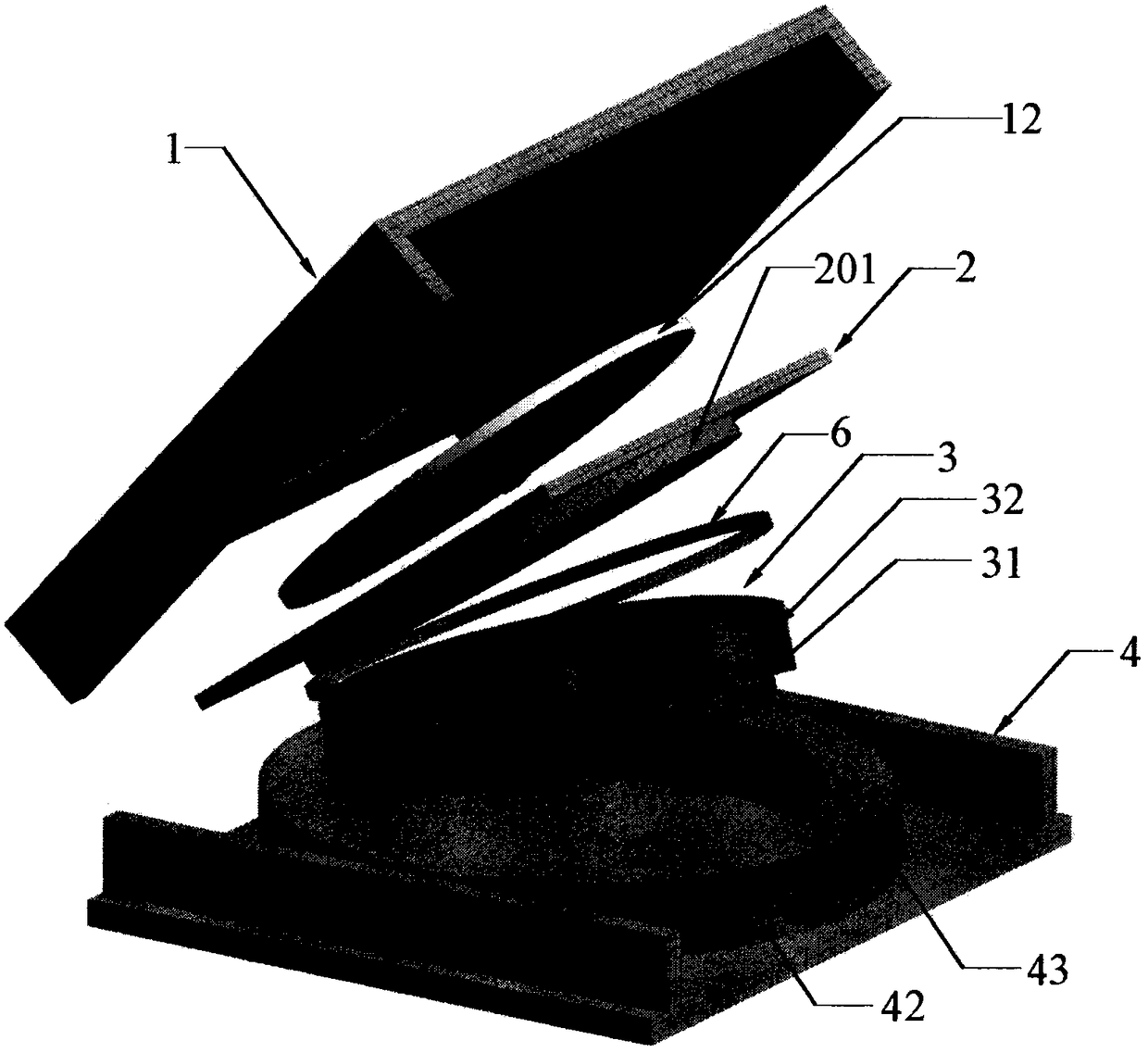

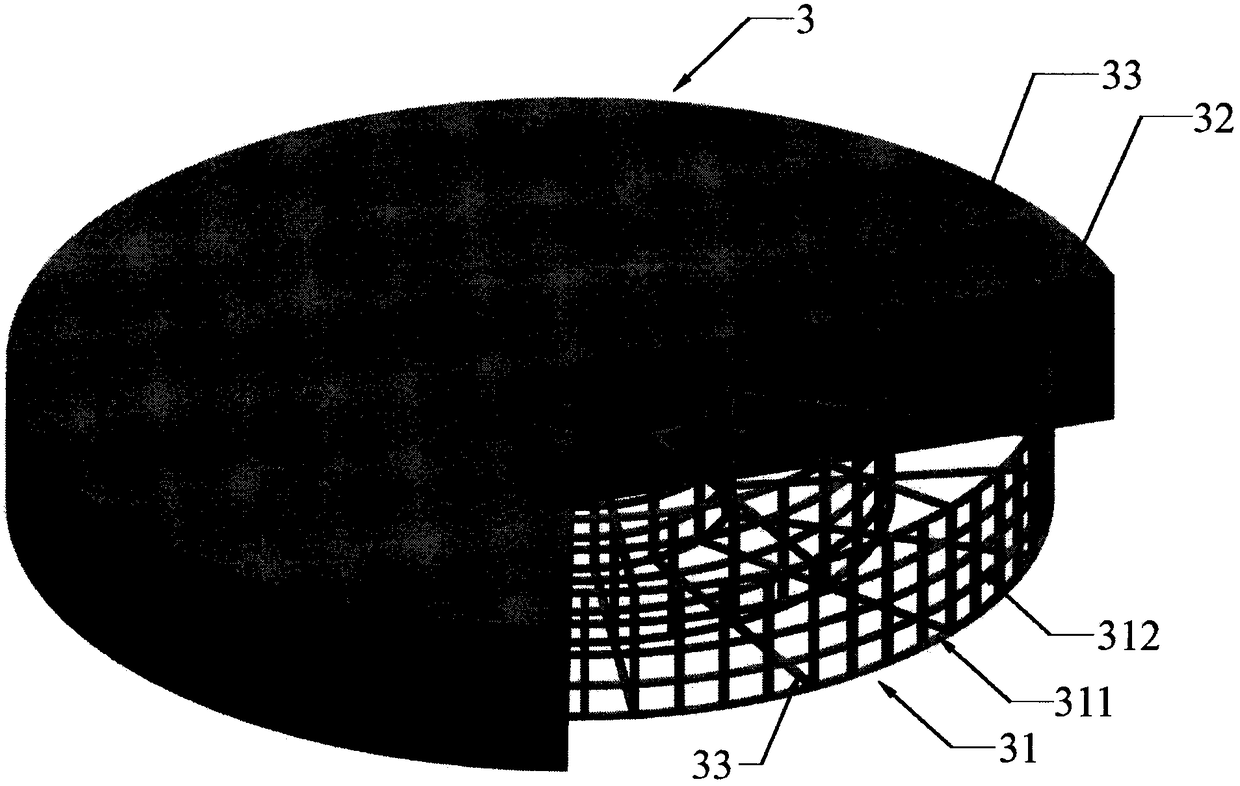

[0033]As shown in the attached figure, an FRP-constrained pot-type rubber bearing, more than one layer of FRP sheet wrapping layer 5 is respectively wrapped and bonded to the steel upper seat plate 11, the steel middle plate 21 and the steel bottom basin 41 through dipping. , to form a composite upper seat plate 1, a composite middle plate 2 and a composite bottom basin 4. The FRP columnar grid 31 is connected as a whole through the strips 33, and is fully vulcanized into one with the rubber layer 32 to form a reinforced rubber layer 3, and the reinforced rubber Layer 3 is placed in the composite bottom basin 4, the height of the reinforced rubber layer 3 is smaller than the cavity height of the composite bottom basin 4, and the annular protrusion 201 of the composite middle plate 2 is embedded in the composite bottom basin 4, located on the upper part of the reinforced rubber layer 3, and Set the sealing ring 6 at the joint between the annular protrusion 201 and the composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com