Continuously variable transmission used for forklift

A variable-speed transmission and forklift technology, which is applied in transmission devices, fluid transmission devices, belts/chains/gears, etc., can solve the problems of difficult starting and shifting operations, high energy consumption, and low transmission efficiency of torque converters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

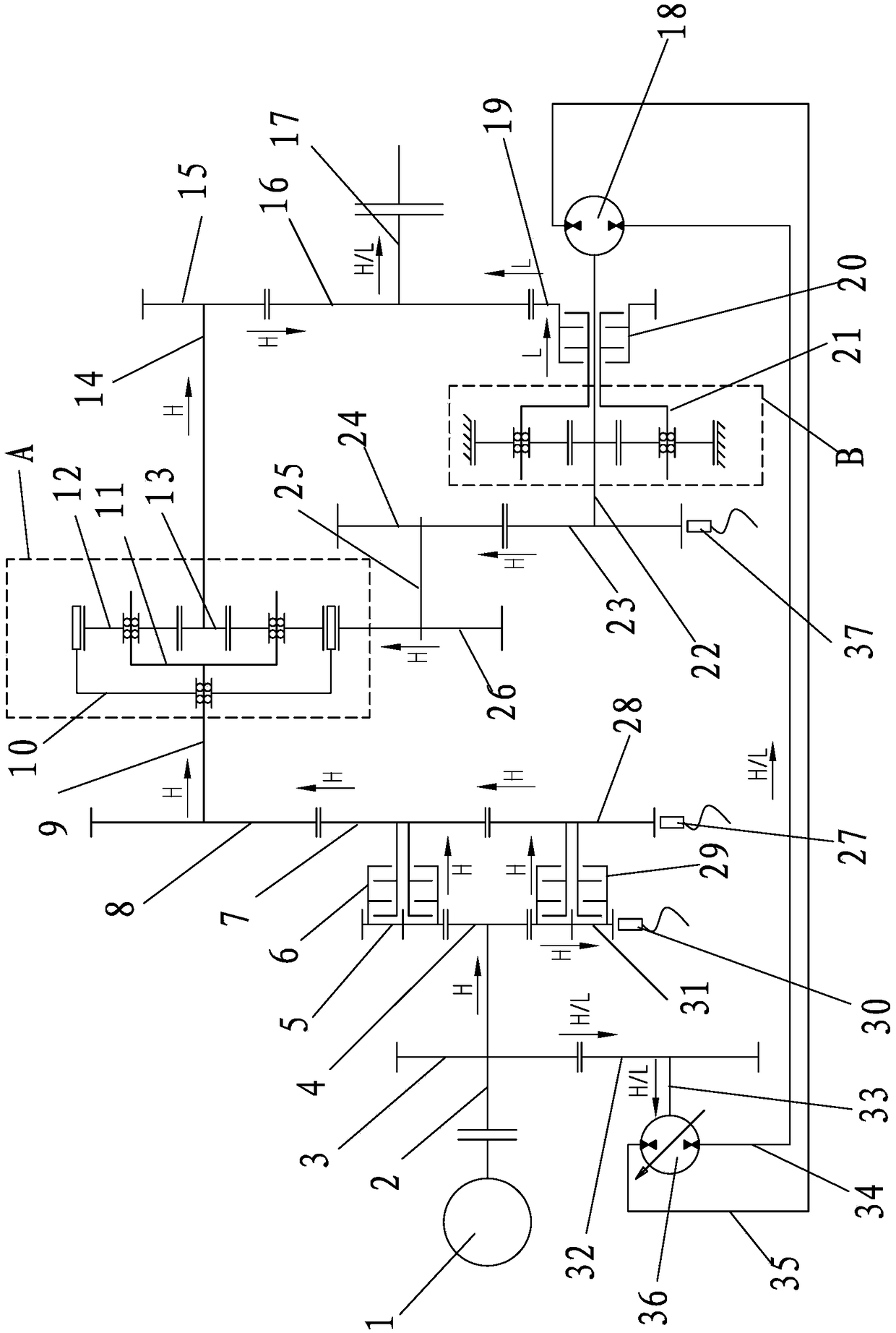

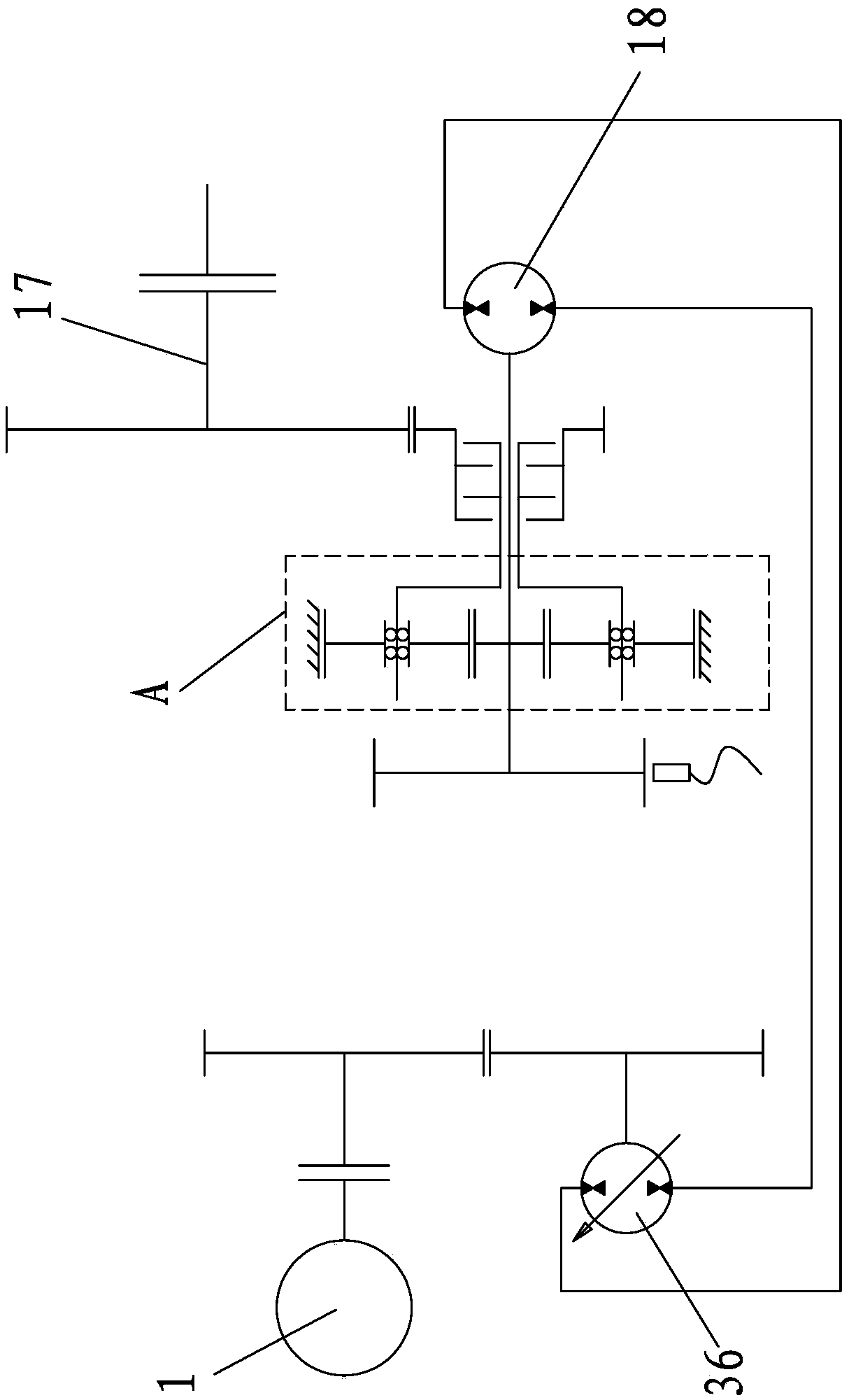

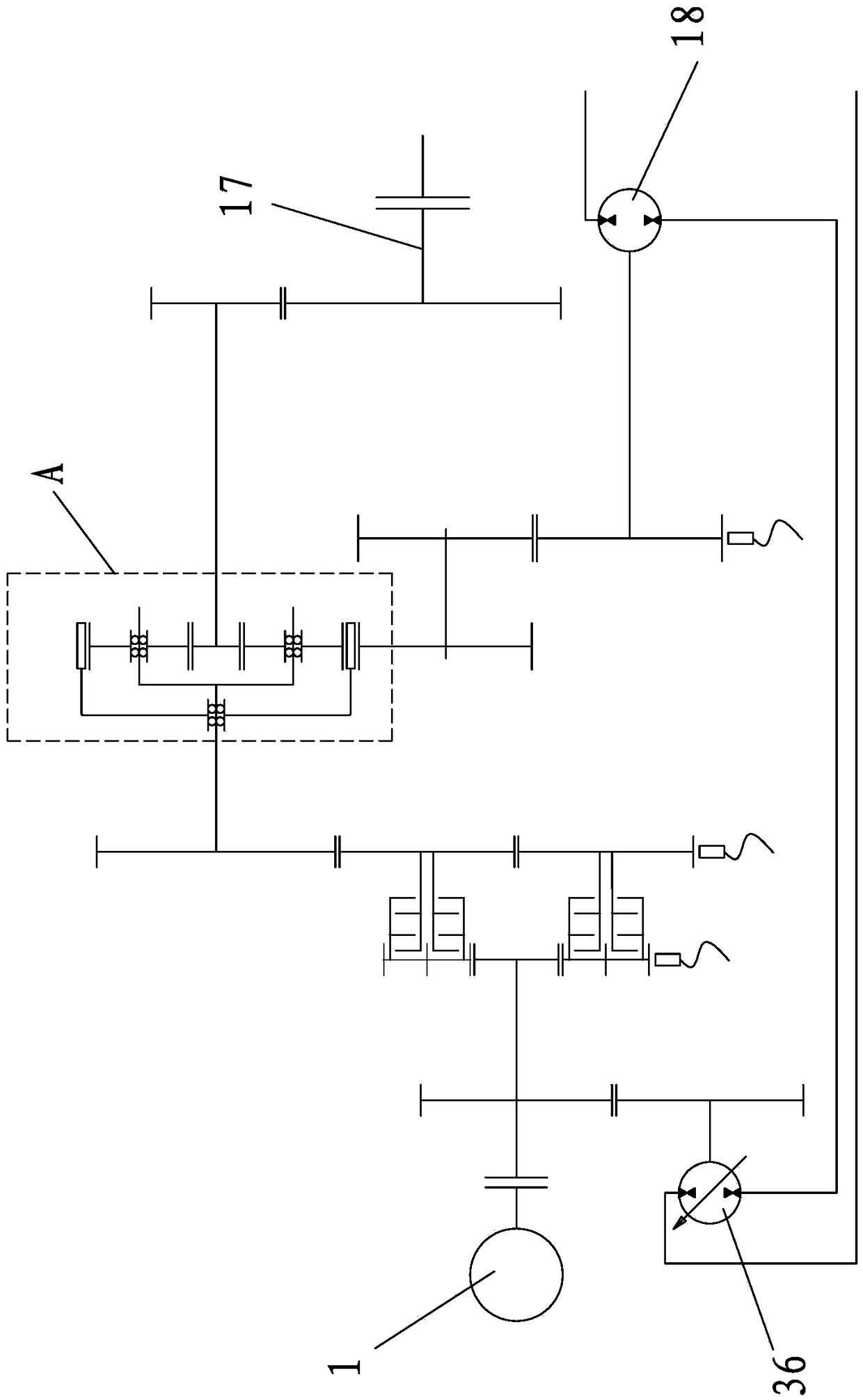

[0023] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0024] refer to Figure 1 to Figure 6 , a continuously variable transmission device for a forklift, characterized in that it includes an engine 1, a first gear 3 connected to the output shaft of the engine 1, a second gear 32 meshed with the first gear 3, and an output shaft of the engine 1 The third gear 4 in drive connection, the fourth gear 5 meshing with the third gear 4, the fifth gear 31 meshing with the third gear 4, the sixth gear 7, the seventh gear 28, the eighth gear 8, and the planetary gear mechanism A. The ninth gear 15, the tenth gear 16, the eleventh gear 19, the twelfth gear 23, the first hydraulic pump / motor 36 and the second hydraulic pump / motor 18, the first hydraulic pump / motor 36 and the second hydraulic pump / motor The hydraulic pump / motor 18 communicates with the second oil pipe 35 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com